Air suction type safety valve

A safety valve and air extraction technology, which is applied in the field of safety valves, can solve problems such as slow seat return, valve opening height, discharge time and speed that cannot be adjusted on site, and flow that cannot be adjusted and controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

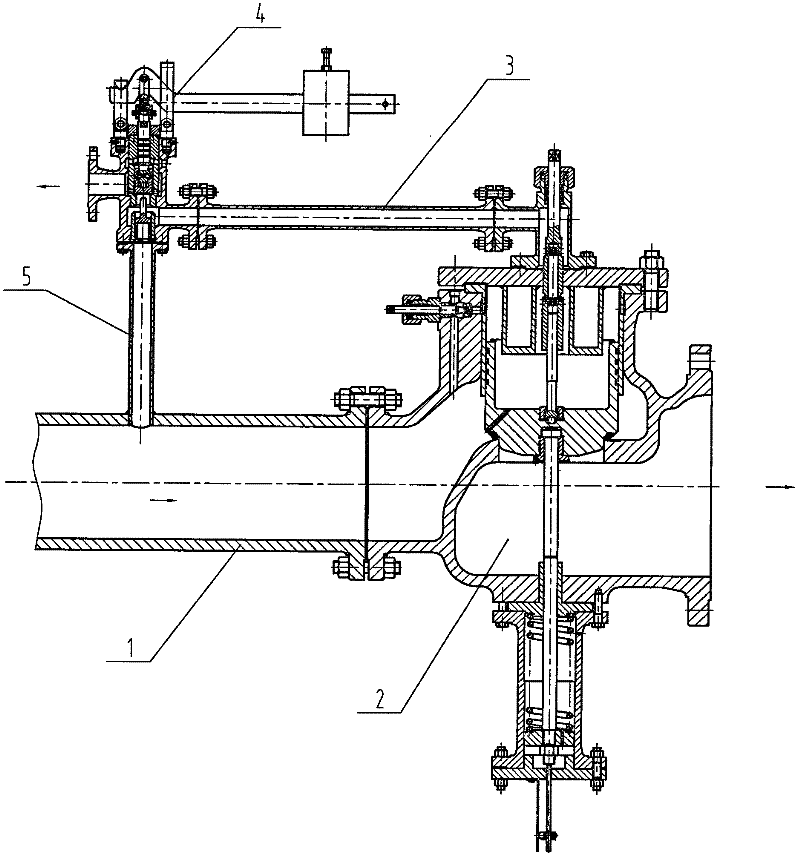

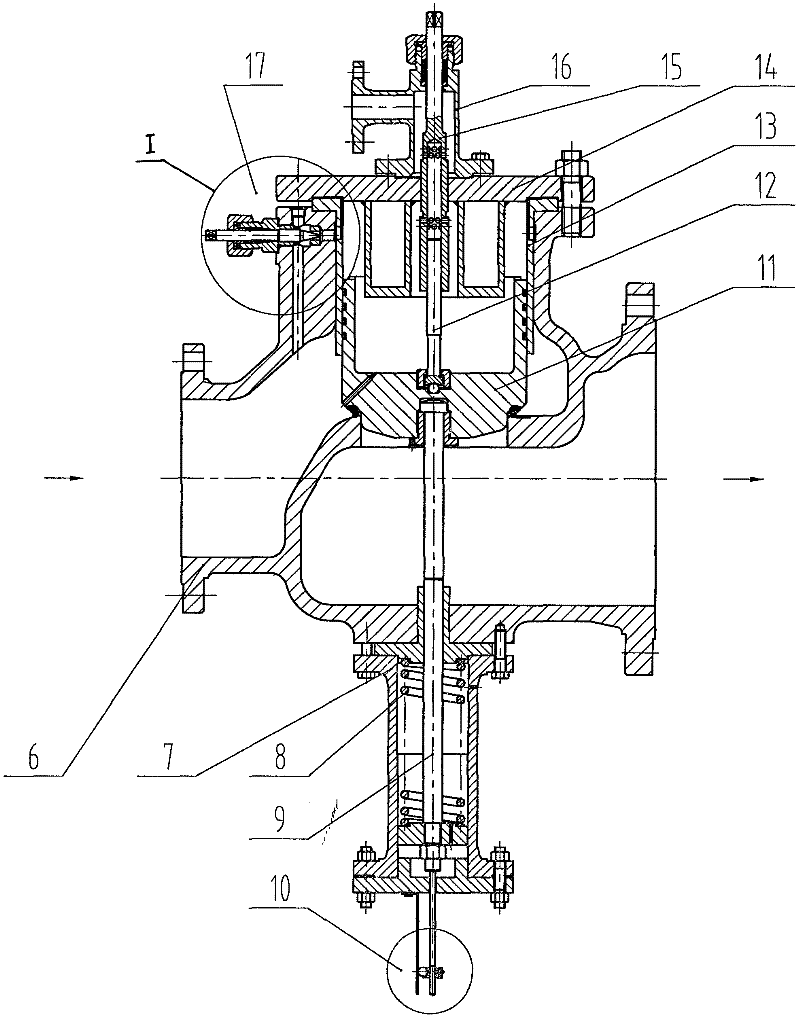

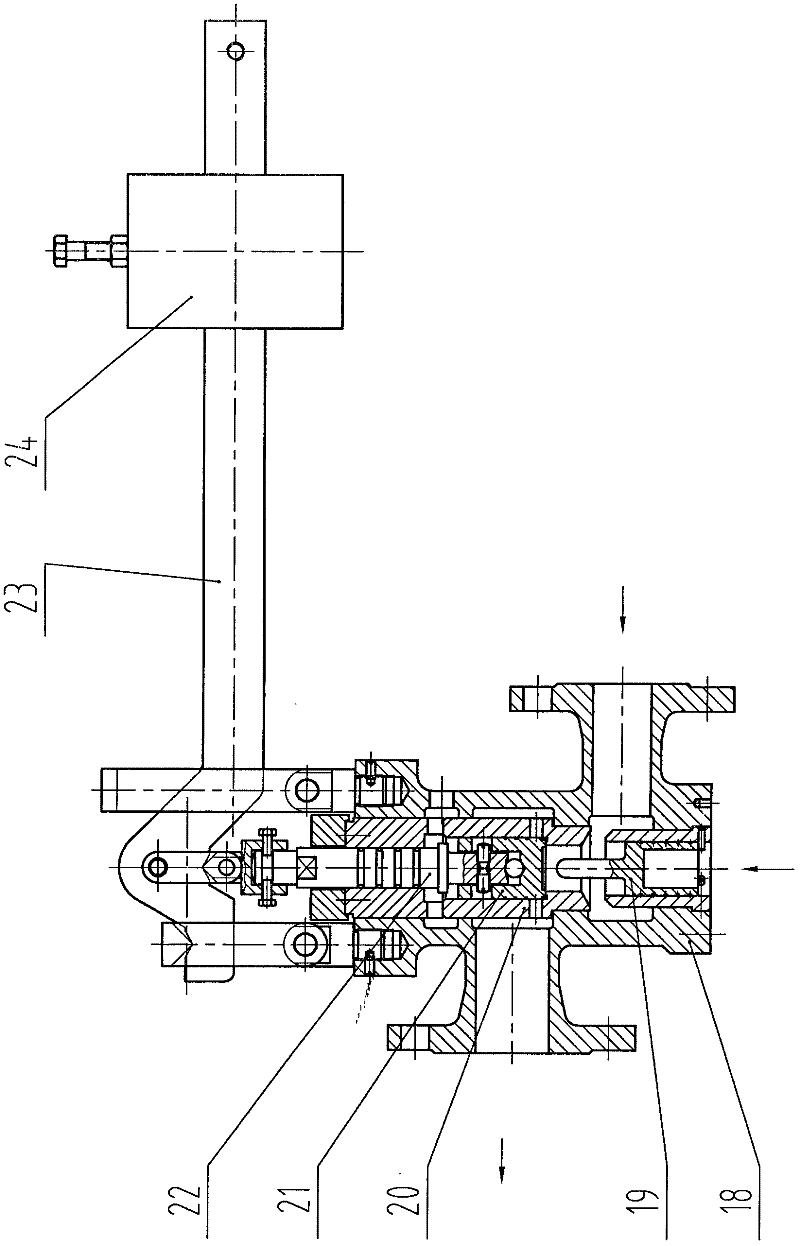

[0015] Such as figure 1 The suction type safety valve shown includes a main valve 2 and a pilot valve 4. The main valve 2 includes a valve body 6, a disc 11, a valve cover 14, and a valve stem. The valve stem is composed of an upper valve stem 12 and a lower valve stem 9. , the lower end of the upper valve rod 12 is fixed on the center of the upper plane of the valve disc 11 . There is an upwardly extending cylinder on the outer edge of the upper end surface of the valve disc 11. A piston cavity is formed between the cylinder and the valve cavity on the inlet side of the valve body 6 and the valve cover 14. The valve disc 11 is connected to the inlet channel of the valve body 6 and the piston cavity. small hole. The valve body 6 is formed with a through hole communicating with the inlet passage and the piston cavity, and a flow regulator 17 is arranged on the through hole. A height adjustment screw sleeve 15 is installed between the valve cover 14 and the piston chamber, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com