A method for predicting the flow of large low-head pumps

A technology of pump flow and low head, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high measurement accuracy, limited simplicity, and the truncation error of the fitting equation cannot be determined according to the proportional ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

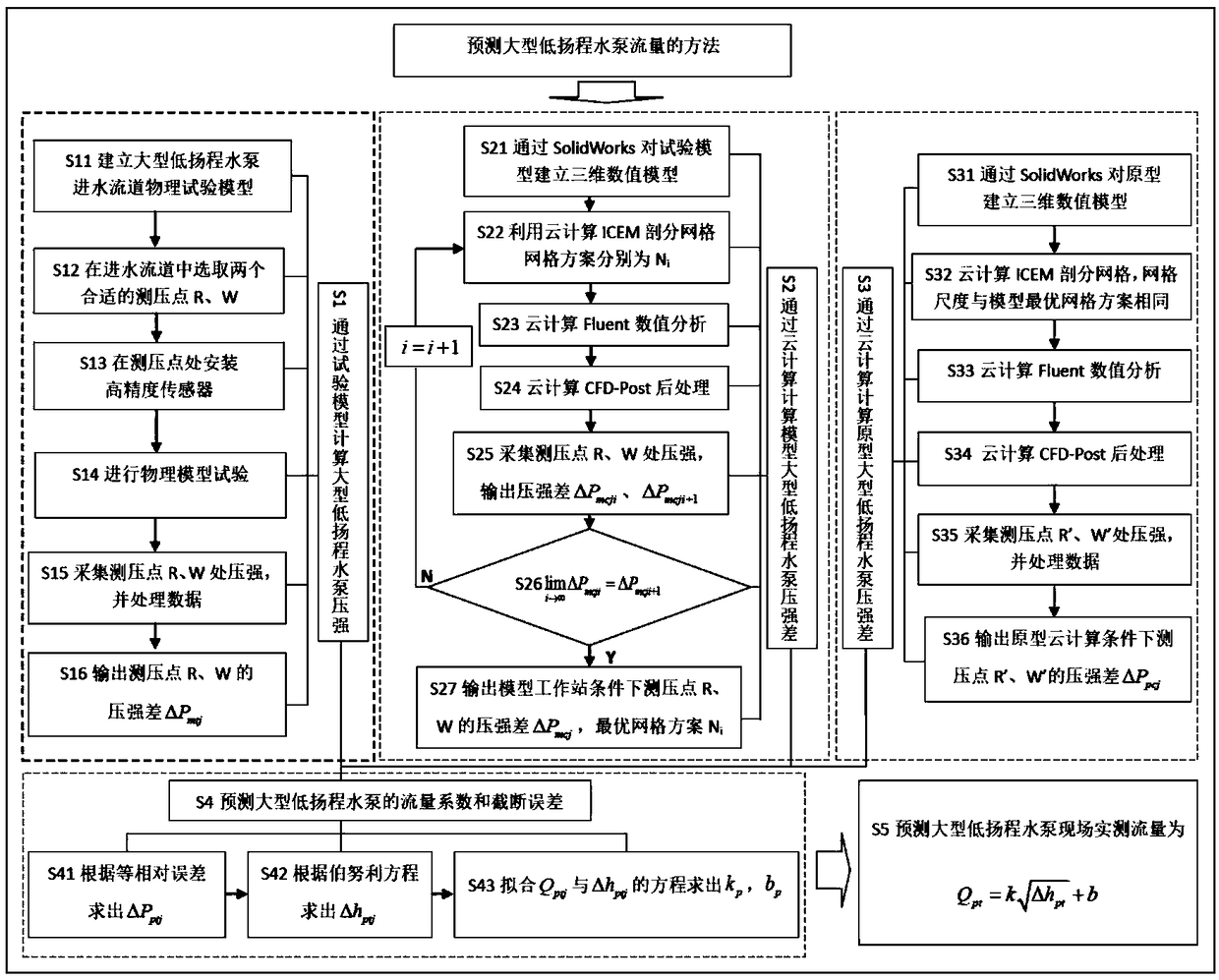

[0043] like figure 1 Shown is a flow chart of the method for predicting the flow rate of a large-scale low-lift water pump of the present invention. The method for predicting the flow rate of a large-scale low-lift water pump in this embodiment first establishes a physical test model of a large-scale low-lift water pump inlet flow channel, selects two suitable pressure measurement points in the water inlet flow channel, and installs high-precision sensors at the two pressure measurement points. , collect the pressures of the two pressure measuring points in the physical model test under different flow conditions, and obtain the pressure difference of each flow rate of the two pressure measuring points under the physical model test conditions; then use the three-dimensional modeling software SolidWorks to build a model of large-scale l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com