A model stage of mcl compressor and its design method

A compressor and model technology, applied in mechanical equipment, engine function, machine/engine, etc., can solve the problems of low unit performance, small shaft diameter, large axial span, etc., achieve high variable efficiency, reduce consumption power, saving energy and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

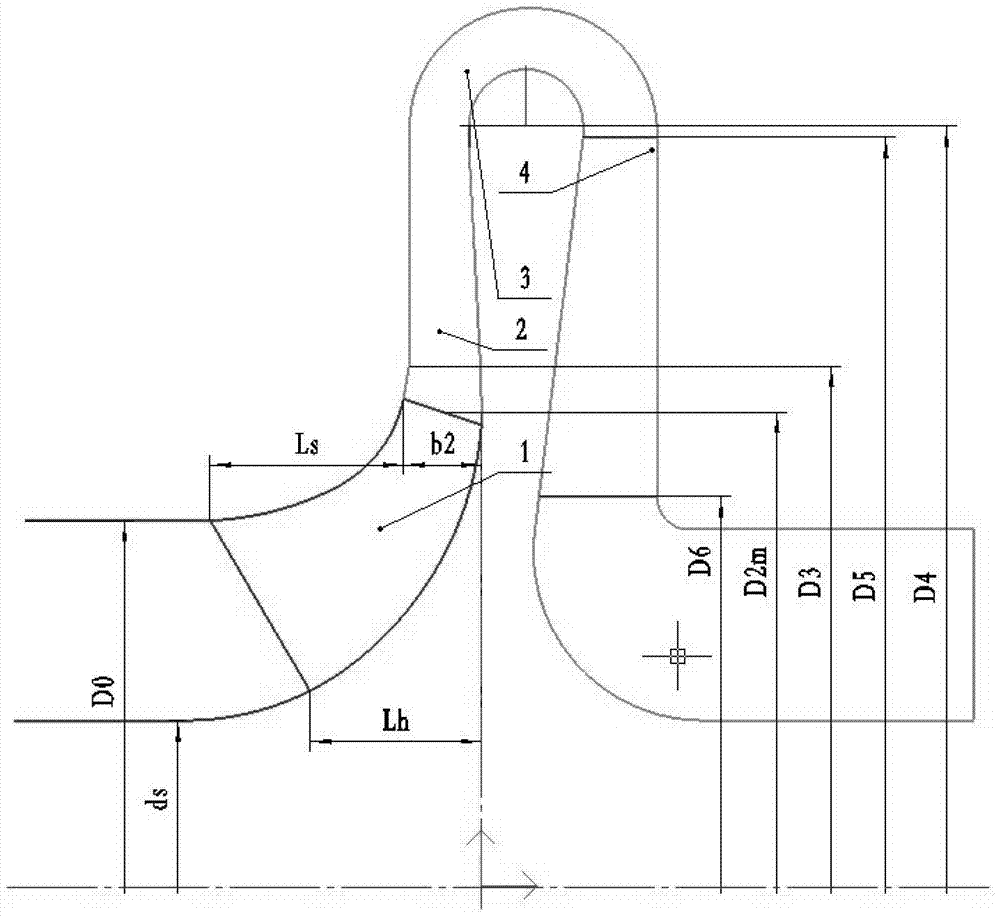

[0082] Such as figure 1 As shown, the structure of the meridian flow channel of the MCL compressor model stage of the present invention is as follows:

[0083] The MCL model stage is located in the compressor and is provided with an impeller 1, a vaneless diffuser 2, a curve 3, and a reflux device 4. The impeller 1 is set at the inlet of the model stage, and the reflux device 4 is set at the outlet of the model stage; The impeller 1 is a closed ternary flow impeller, and the refluxer 4 adopts full-height banana blades. After design and analysis, the meaning of each dimension in the meridian channel is defined:

[0084] D 0 —The entrance diameter of the cover plate;

[0085] D 2m —The average outer diameter of the impeller outlet;

[0086] D 3 —Inlet diameter of vaneless diffuser;

[0087] D 4 —Exit diameter of vaneless diffuser;

[0088] D 5 —The inlet diameter of the refluxer;

[0089] D 6 —The outlet diameter of the refluxer;

[0090] b 2 —The width of the impeller outlet;

[0091] ds—...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com