Patents

Literature

37results about How to "Reduce working speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

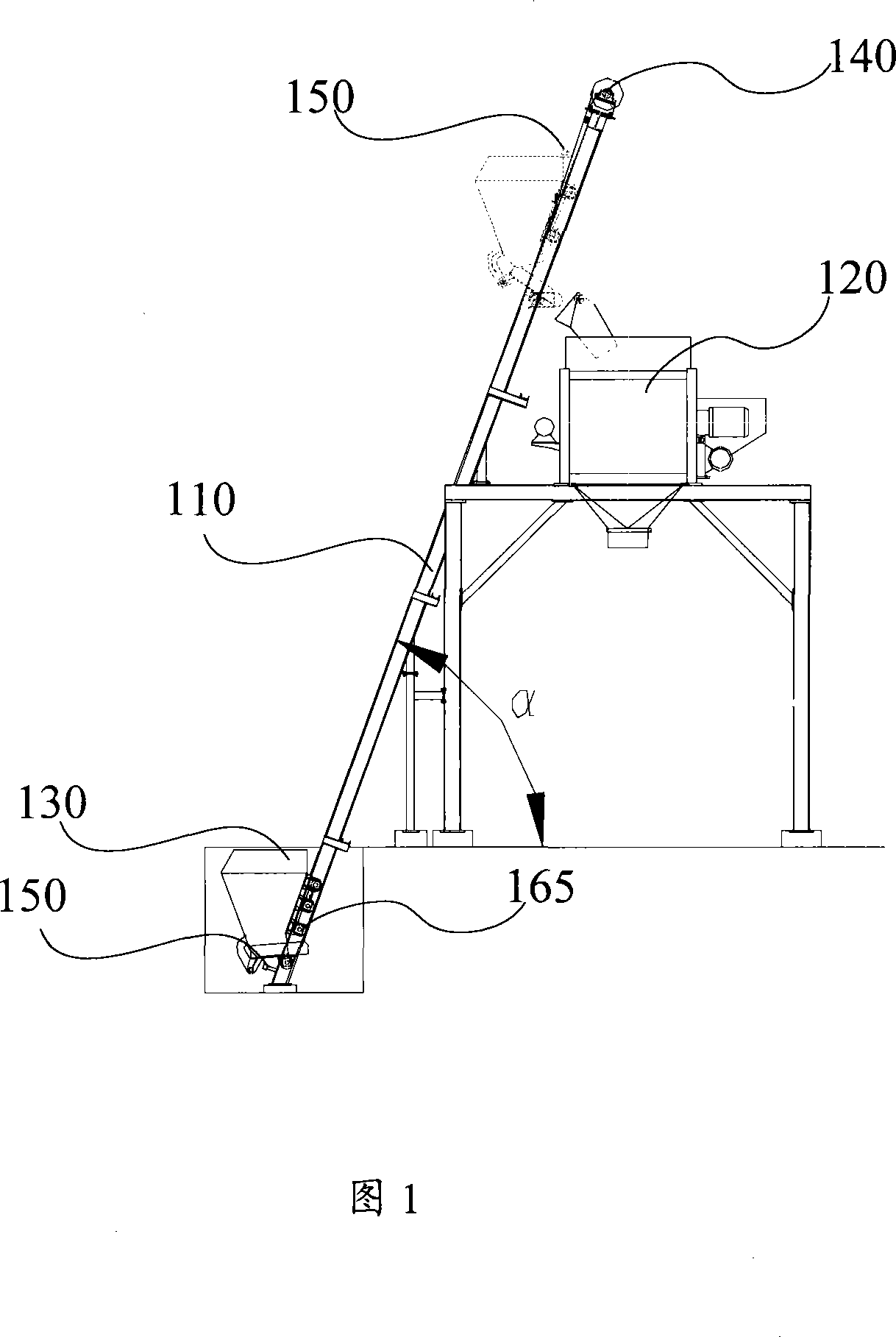

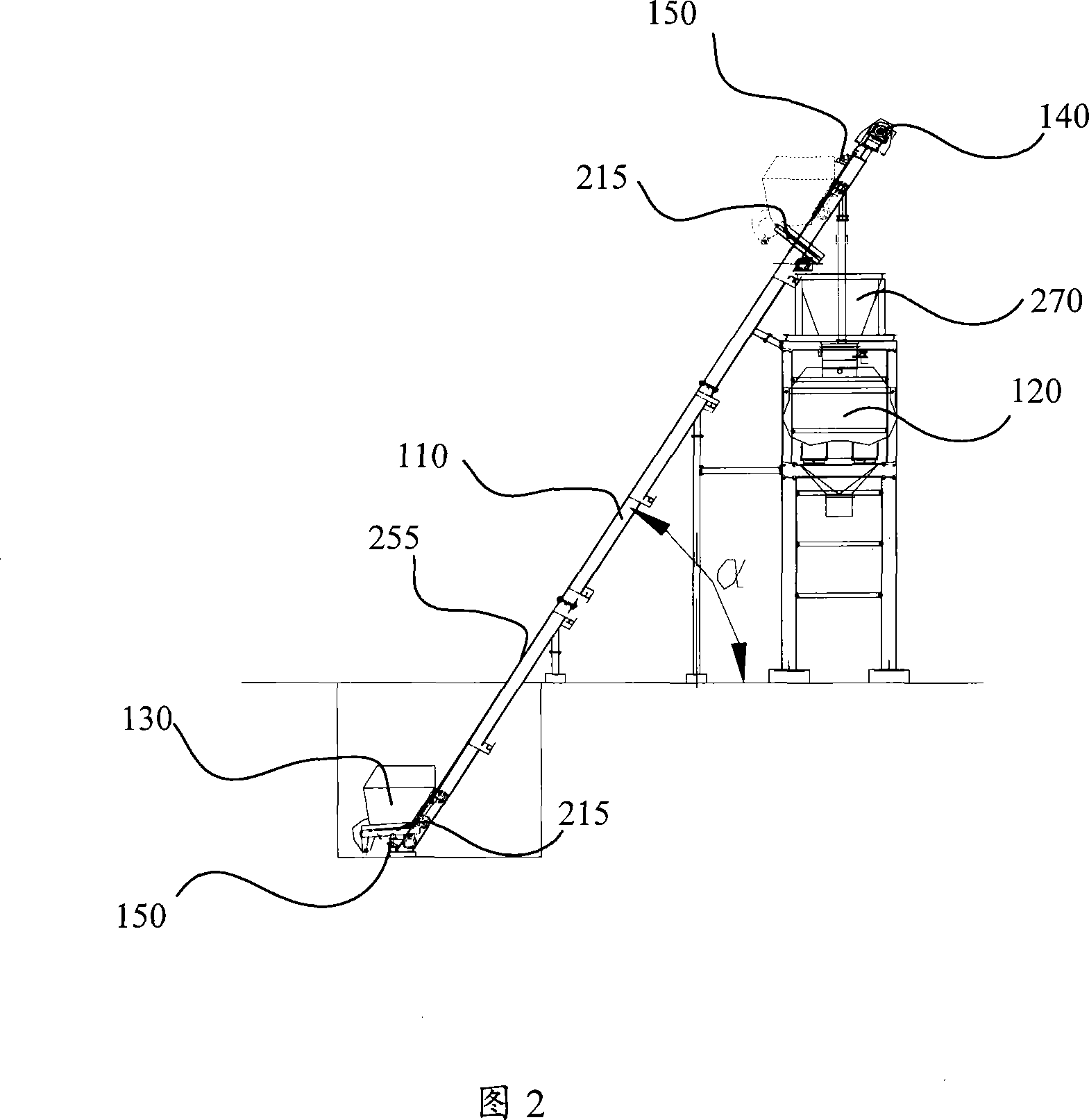

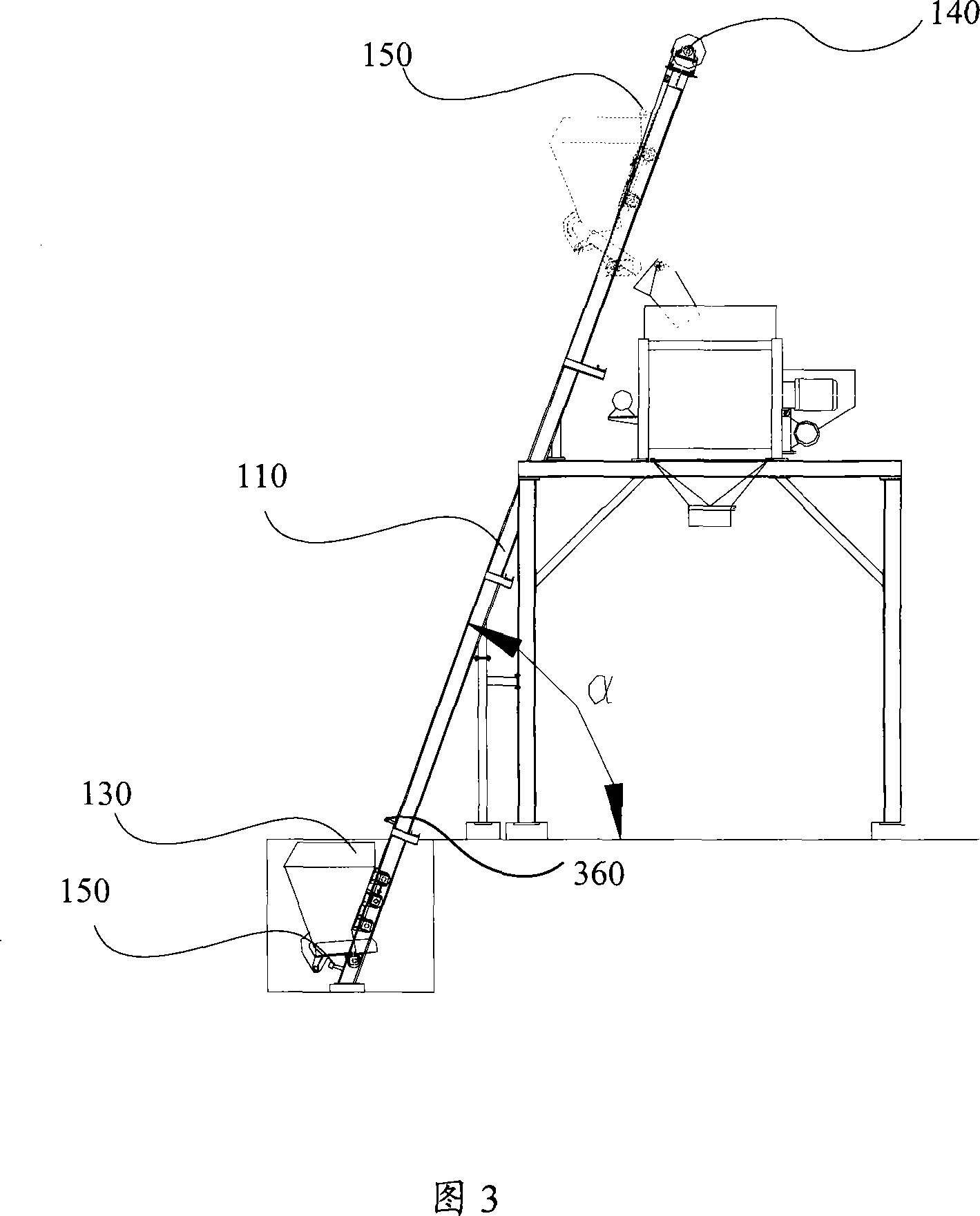

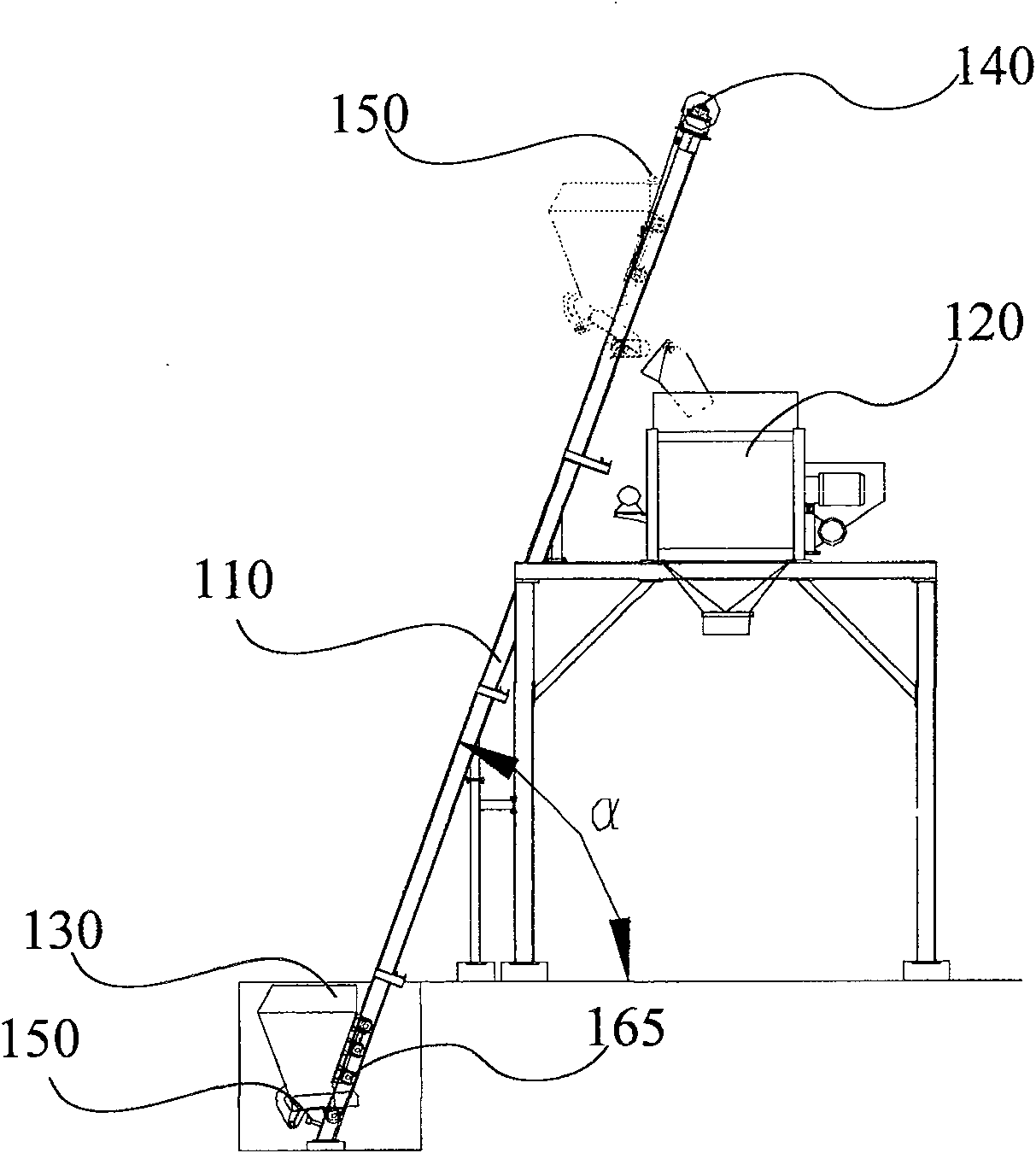

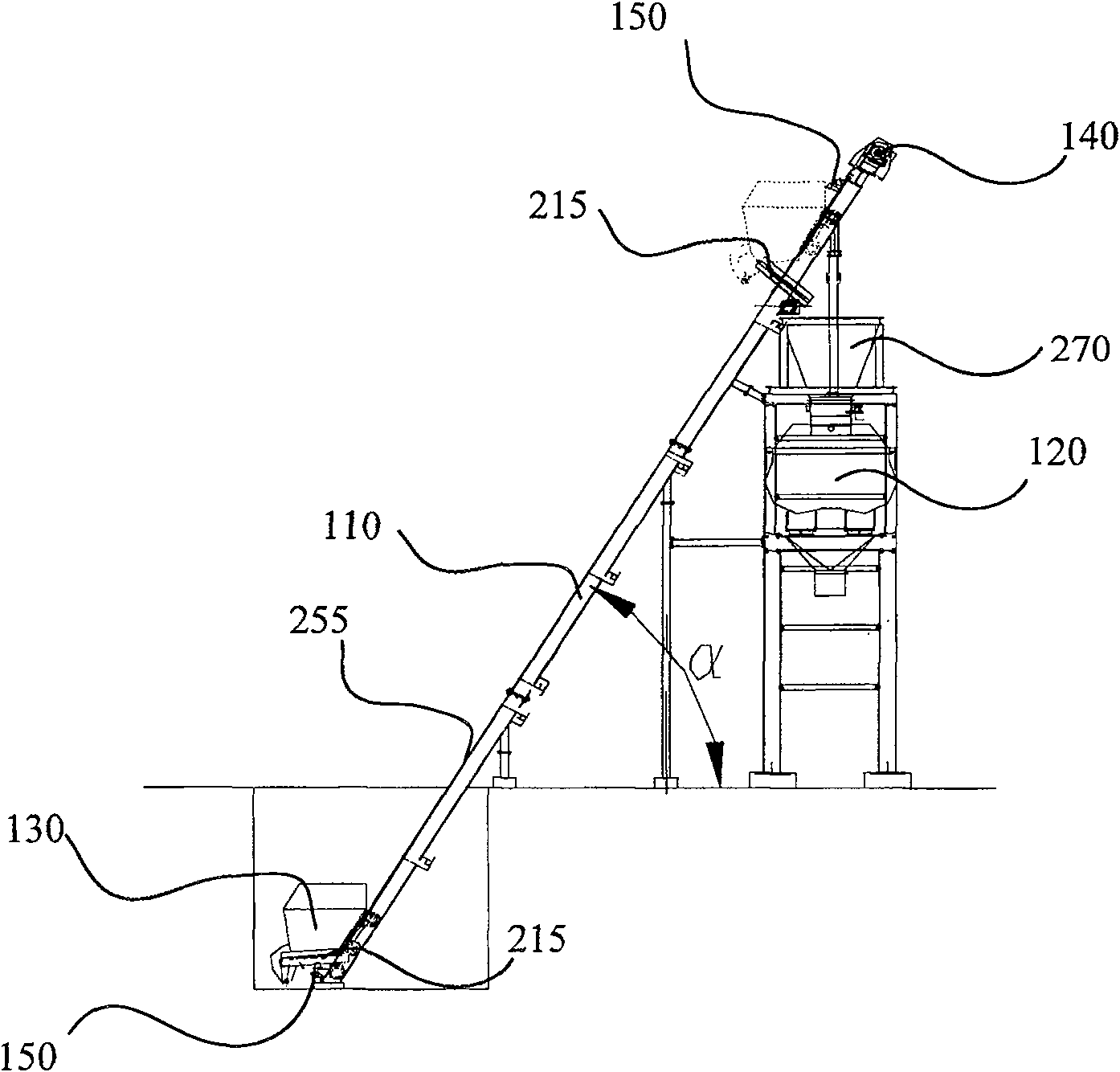

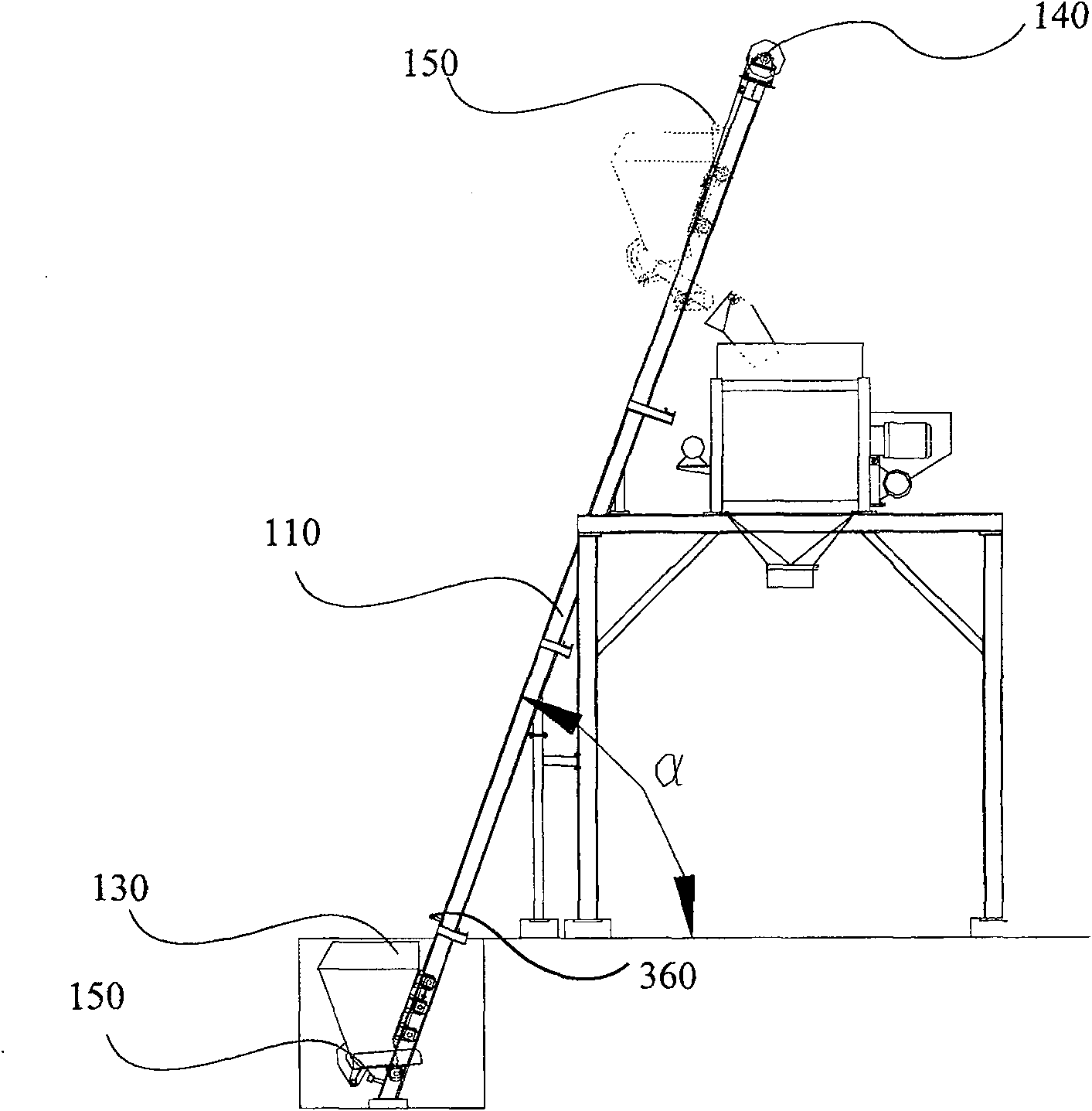

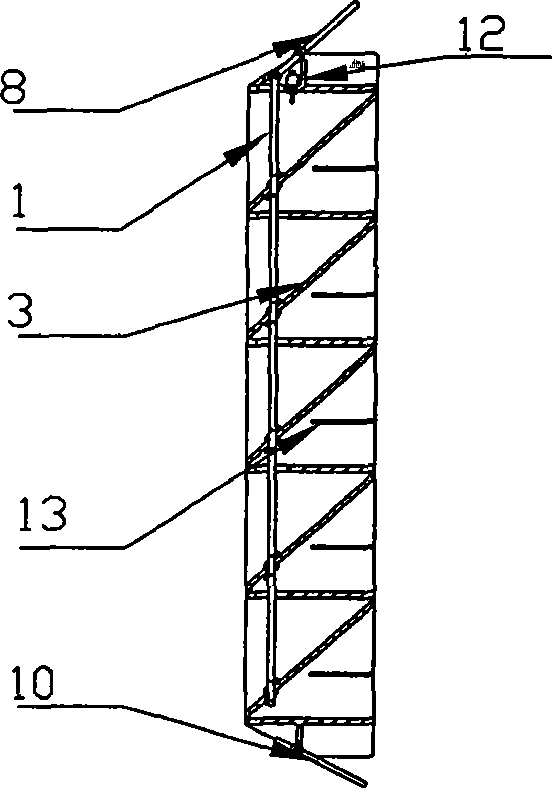

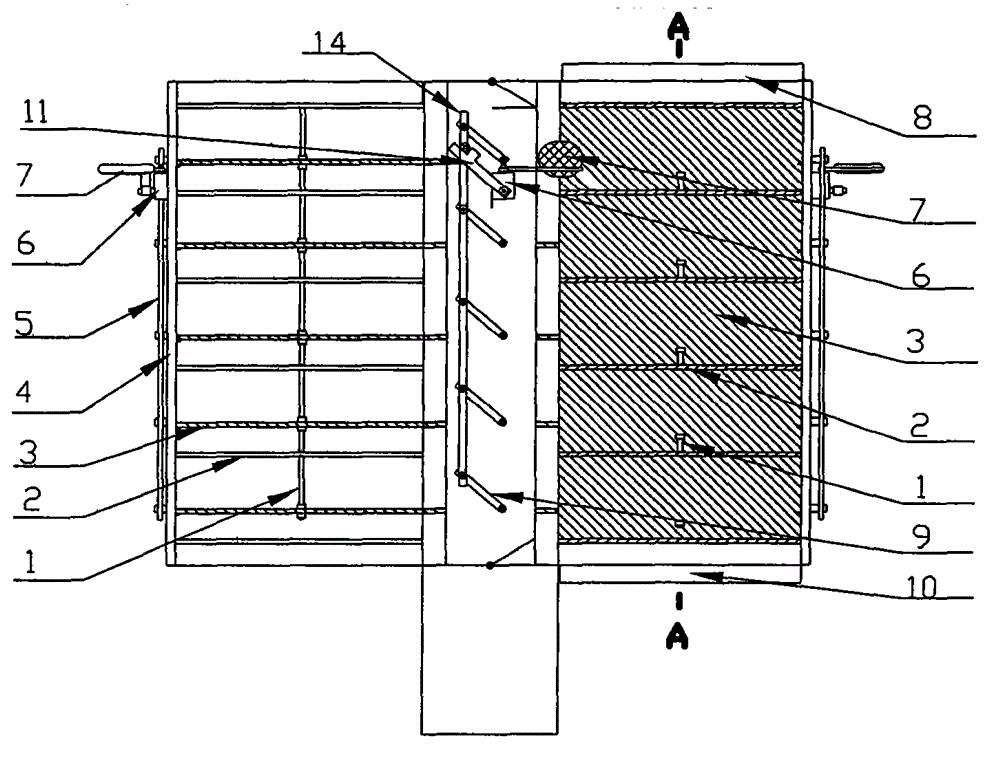

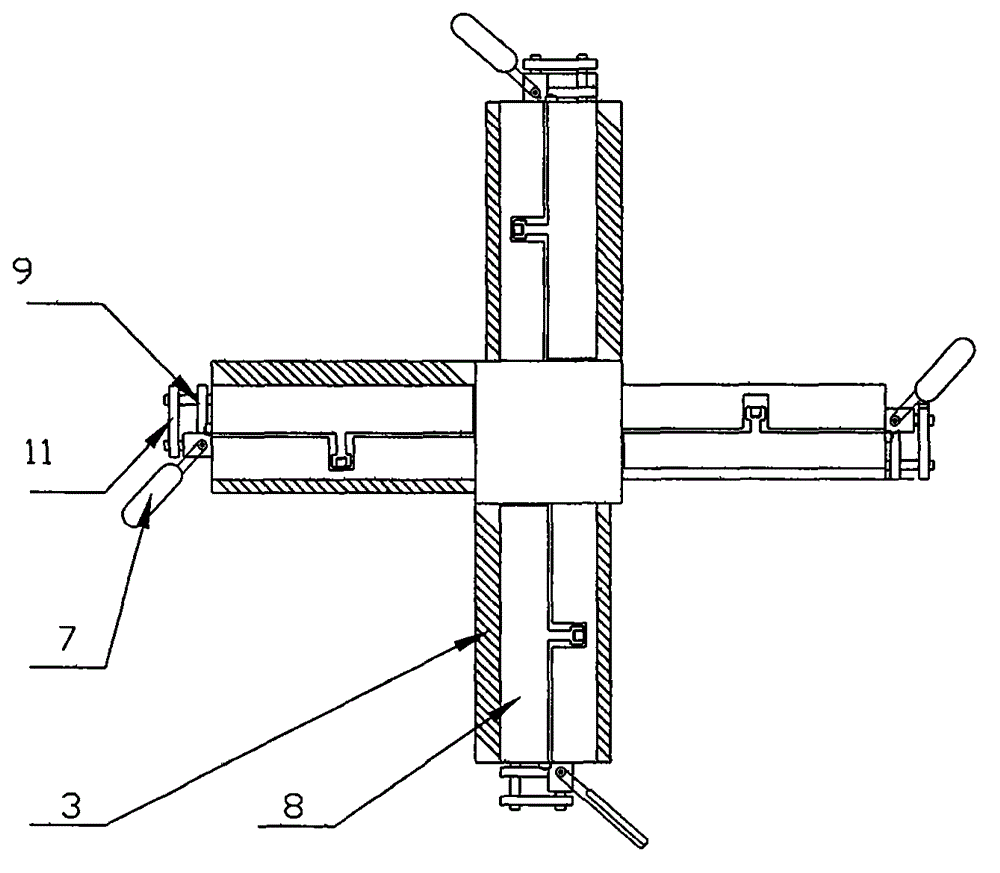

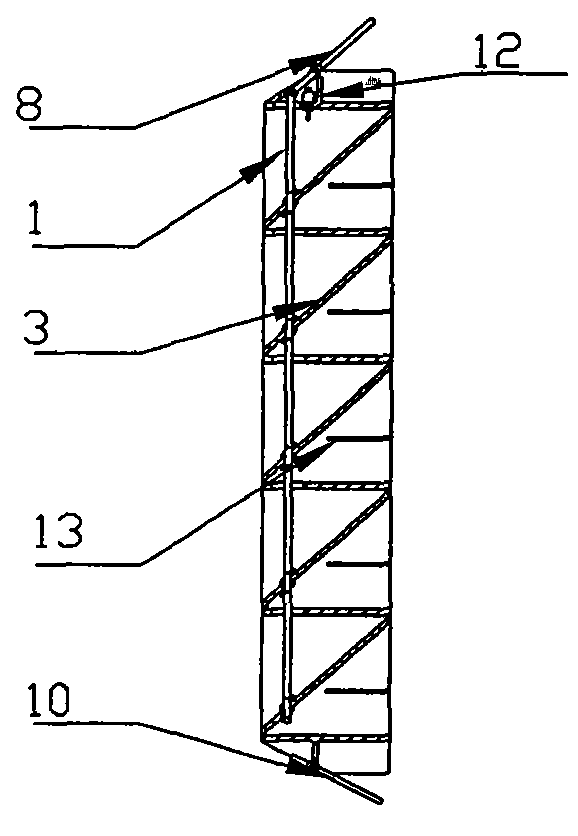

Skeletal material conveyer of concrete station

InactiveCN101219562AReduce the installation angle αReduce loadMixing operation control apparatusConstruction aggregateMaterial storage

The invention discloses an aggregate convey device adopted by a concrete mixing station and comprises a lift rail (110), a lift bucket (130), a hoister (140), a shutdown switch (150) and a mixer. The lift rail (110) is placed aslant; the hoister (140) is at the top end of the lift rail (110) and connected with the lift bucket (130) to drive the lift bucket (130) to slide along the lift rail (110). The convey device also comprises a material storage bucket (270) which is arranged above the mixer (120) and the angle Alfa between the lift rail (110) and the level is less than or equal to 60 degrees. The material storage bucket is added in the invention, which separates the working circulation of a lifter and the mixing circulation and enables the lifter to work continuously and meanwhile, reduces the installation angle of the lift rail and the loading of the hoister, thus improving the reliability of the hoister.

Owner:SANY HEAVY IND CO LTD (CN)

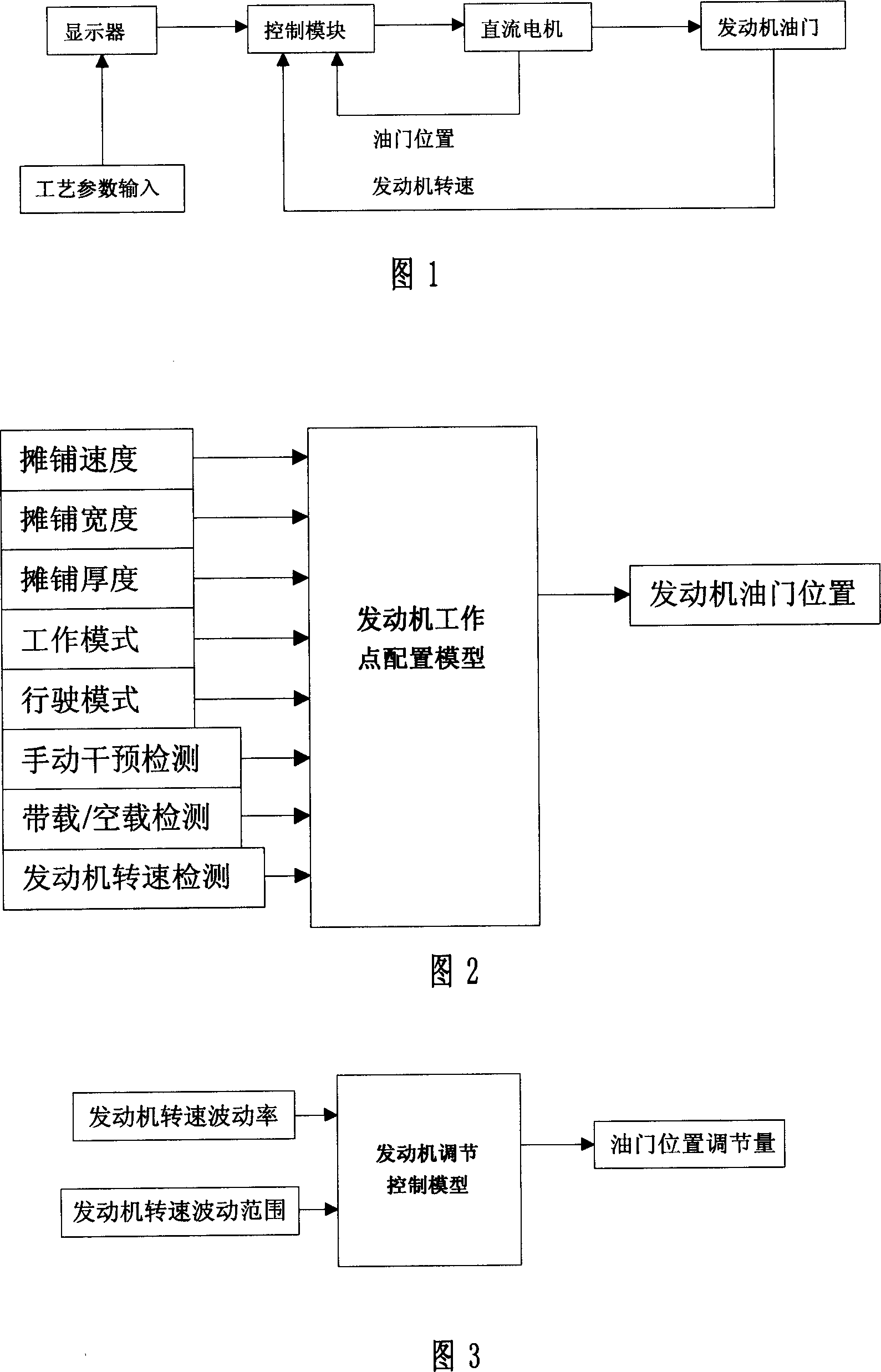

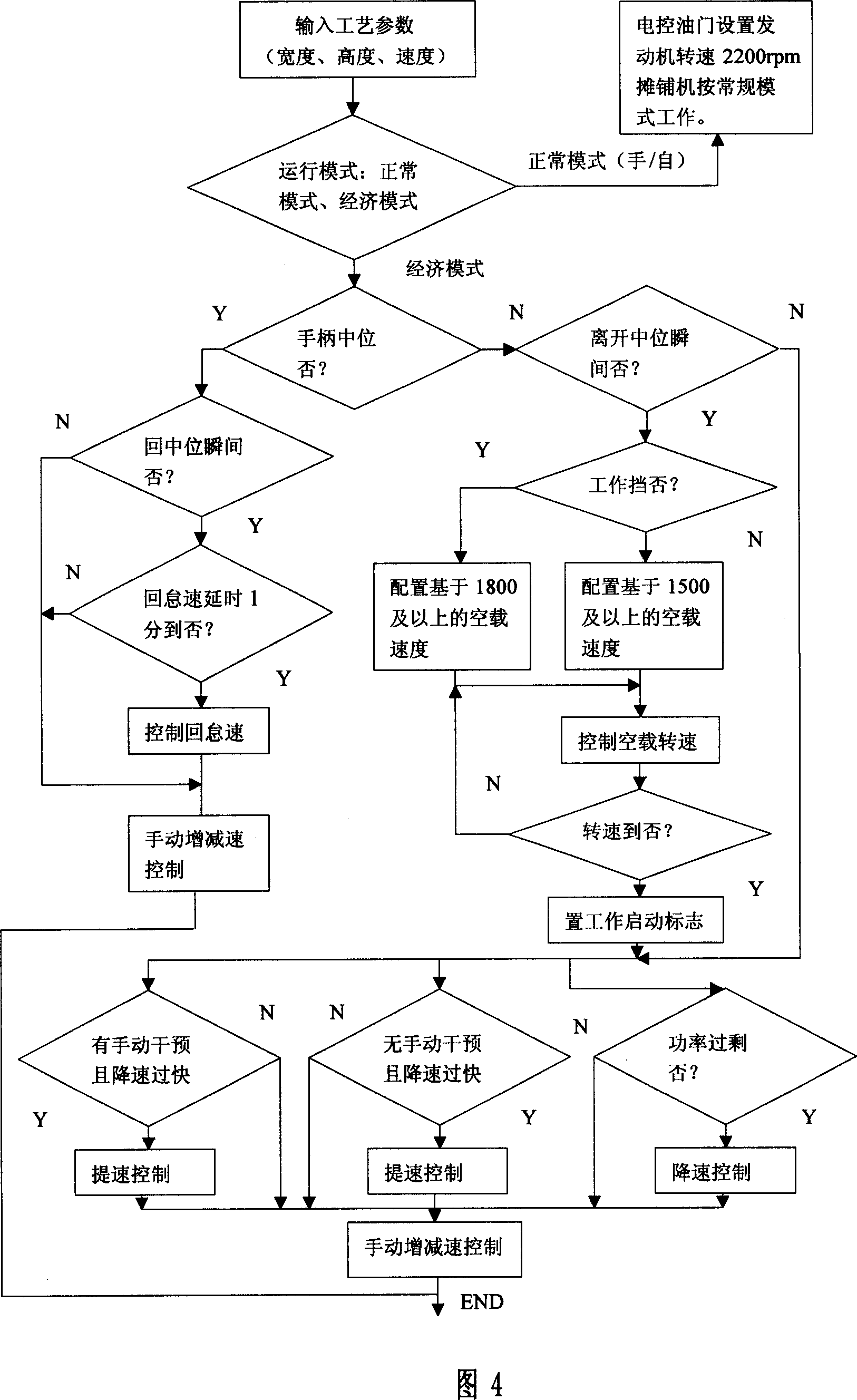

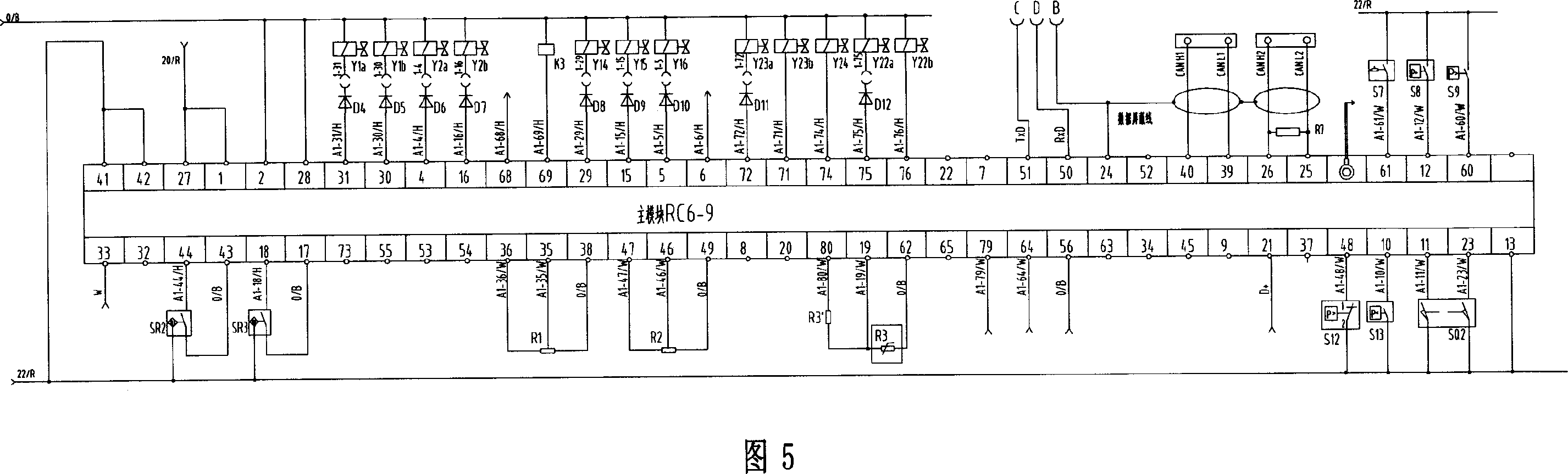

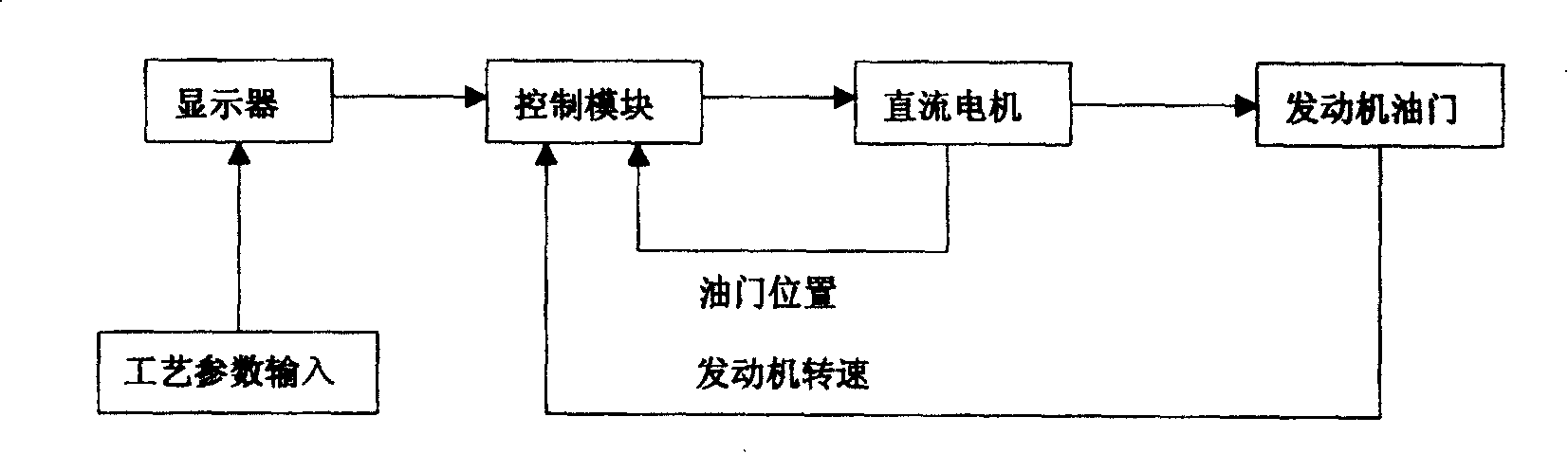

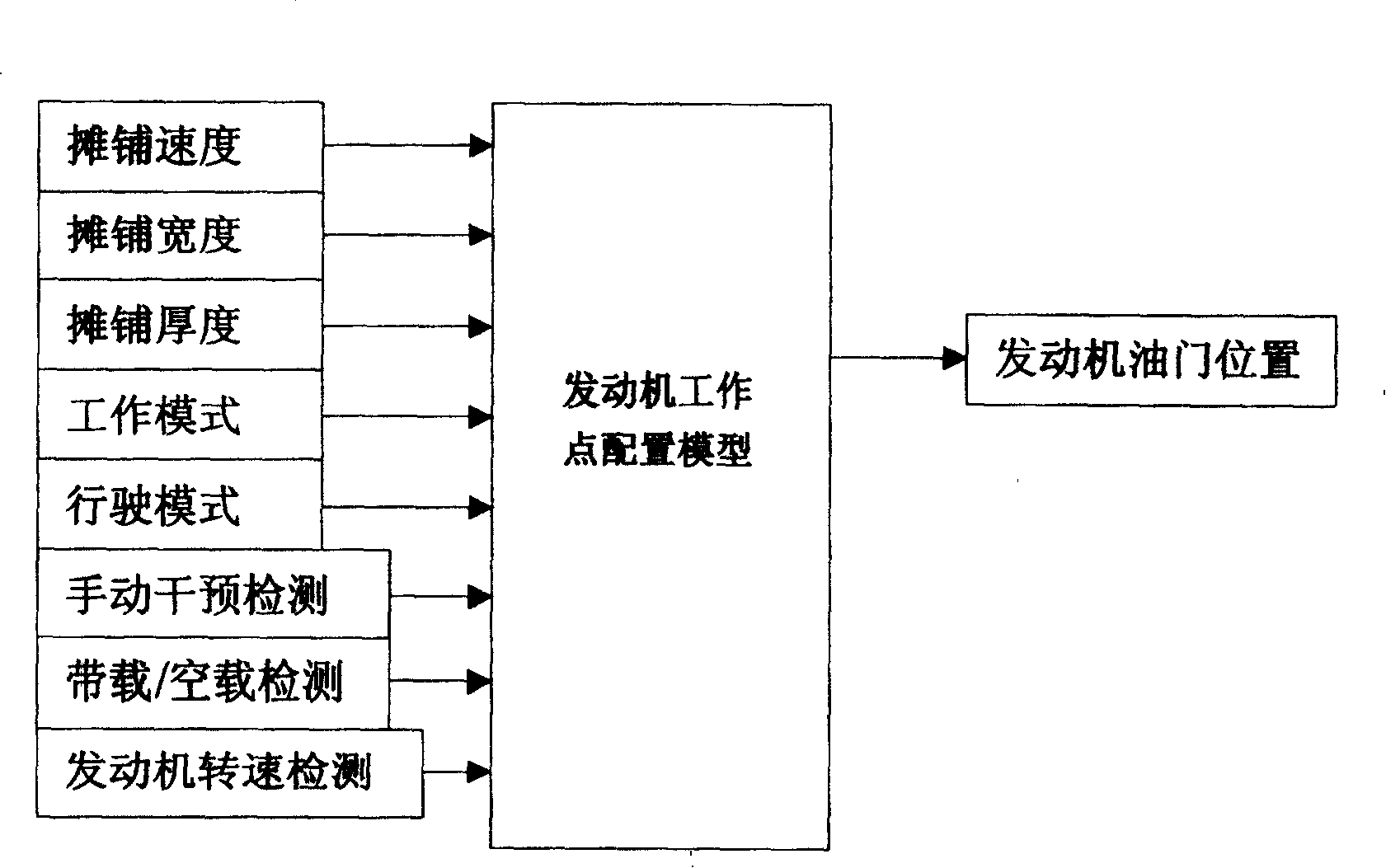

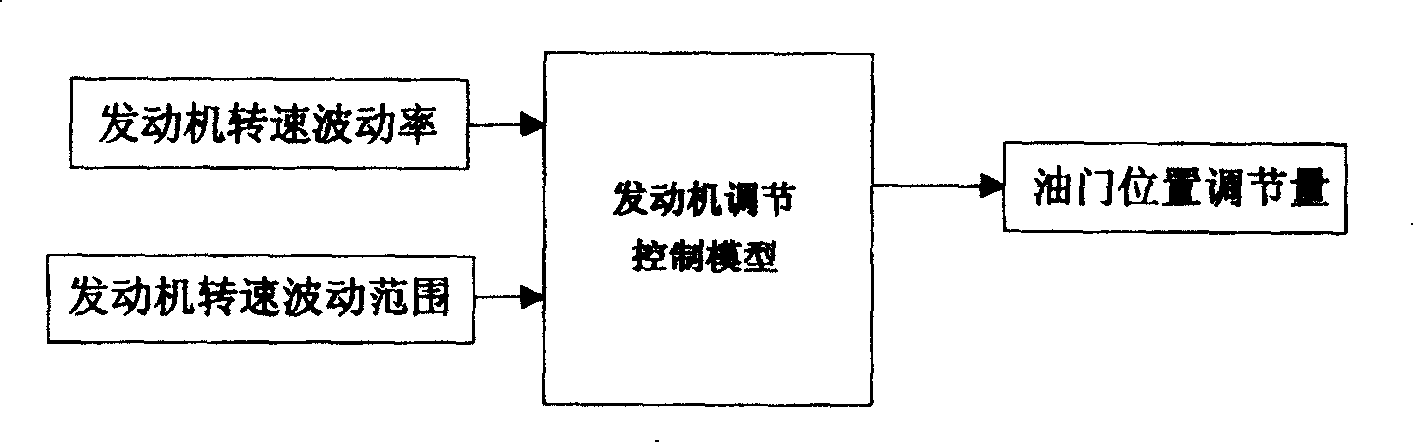

Energy-saving control method for spreading machine

ActiveCN1995543AMeet the output torqueMeet power needsEngine controllersMachines/enginesWork performanceEngineering

The invention discloses an energy-saving control method for paver. Presetting paving thickness, paving width, and paving velocity in paving work are inputted into the collocating cell of engine working point in controller. According to it presetting rotating speed value of engine is obtained. The controller adjusts the engine of paver so that the actual rotating speed of paver is equal to the rotating speed of engine according to the presetting rotating speed value of engine obtained. The method in invention is provided with simple operation, high automaticity. It can adjust the rotating speed of engine according to the change of actual working condition so that not only the whole efficiency is improved but also it is provided with the energy saving under the presence of ensuring working performance.

Owner:SANY HEAVY IND CO LTD (CN)

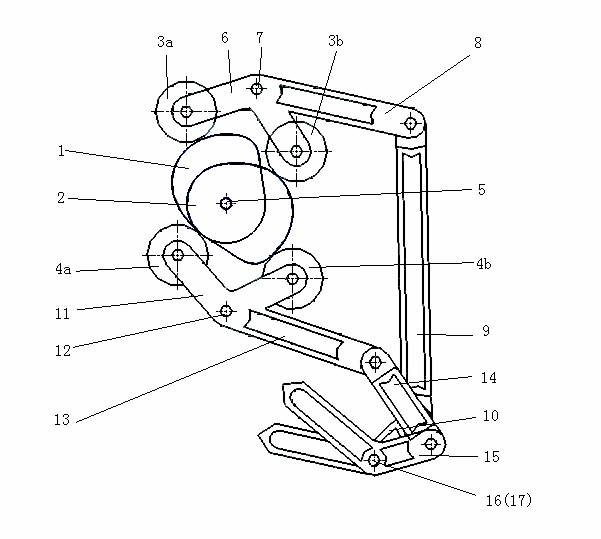

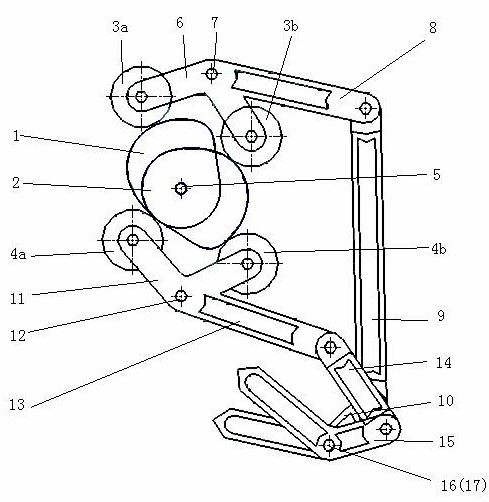

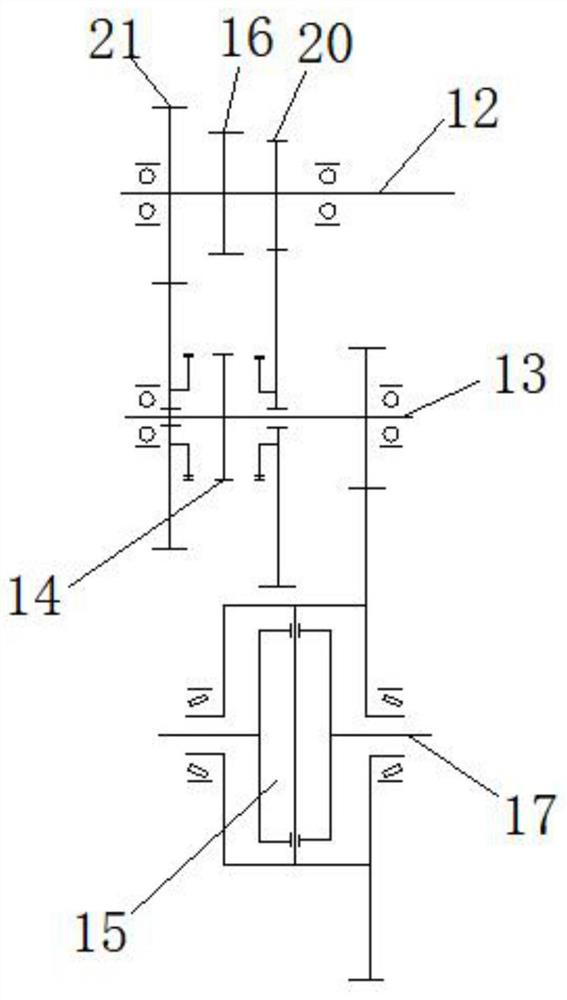

Double-output conjugate cam-connecting rod paper-transferring mechanism

InactiveCN102152979AReduce working speedFast printing speedArticle feedersPaper sheetTransfer mechanism

The invention discloses a double-output conjugate cam-connecting rod paper-transferring mechanism and belongs to the technical field of a paper-transferring mechanism for a sheet-fed offset press. The paper-transferring mechanism is provided with a connecting rod mechanism on the basis of the traditional conjugate cam-connecting rod paper-transferring mechanism, wherein a pair of conjugate cams is matched with two sets of connecting rod mechanisms. The alternative double output of paper sheet is realized, and the rotation speeds of the paper-transferring mechanism and paper-transferring cam are efficiently reduced, thereby reducing the influence of the dynamic property on the mechanism, obviously increasing the paper-transferring speed even under the condition of maintaining the rotation speed of the cam, and lowering the demand on the property of the paper-transferring cam and reducing the aging speed of the mechanism, so the double-output conjugate cam-connecting rod paper-transferring mechanism has the advantages that the motion output is accurate, high-efficient and stable, the operation is easy, and the mechanism is fit for being applied to the sheet-fed offset press or other printing equipment.

Owner:SHANGHAI UNIV

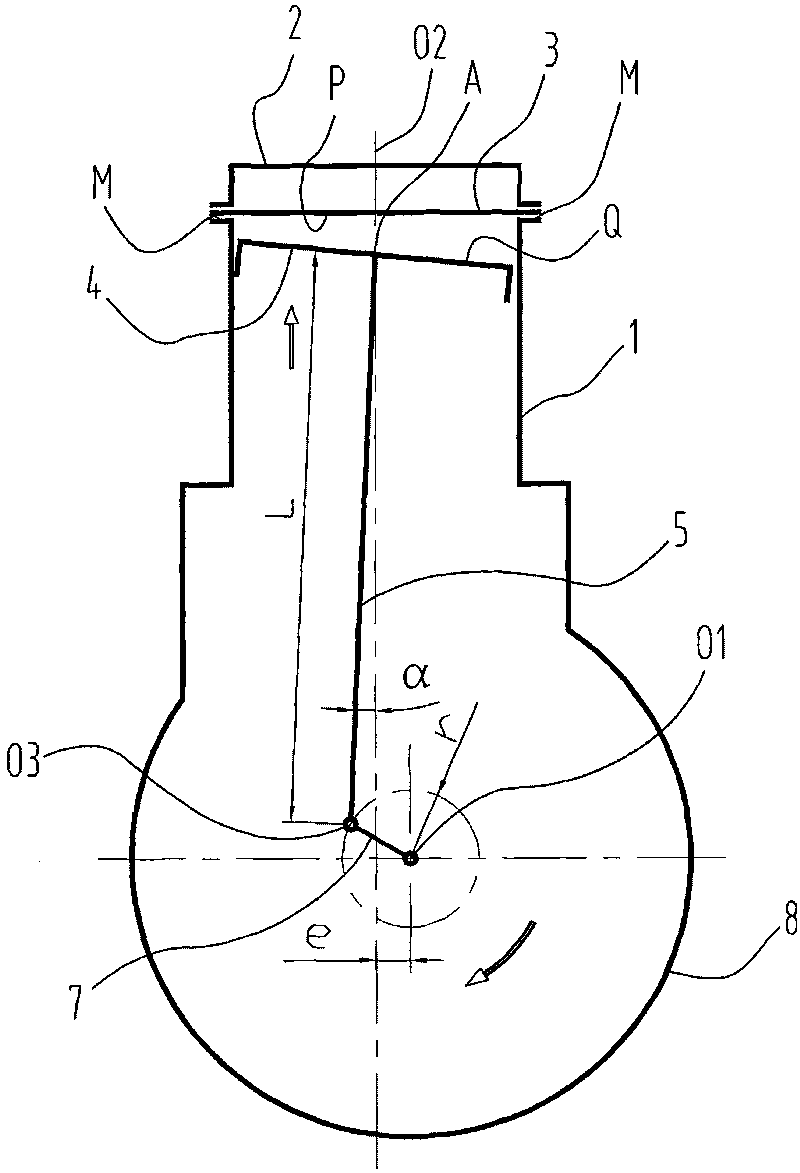

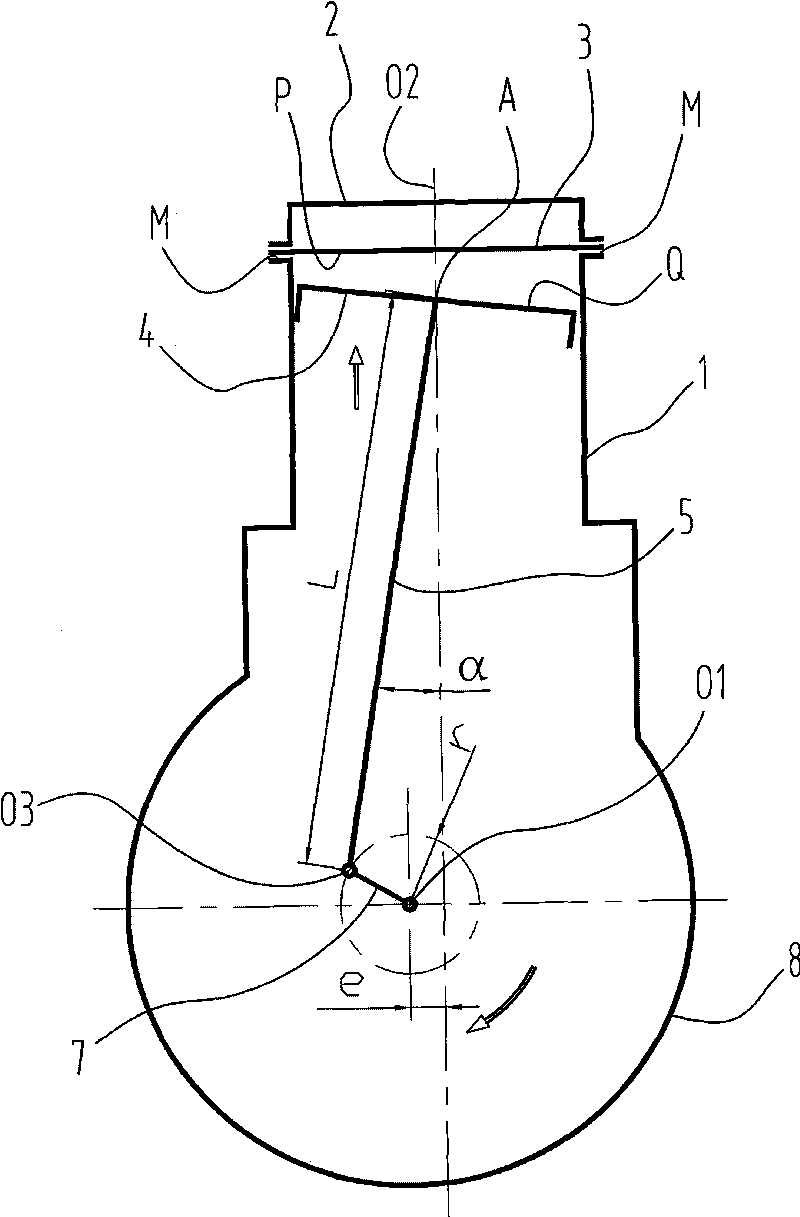

Reciprocating-piston type oil-less air compressor

InactiveCN101737297AReduce side pressureReduce slapping intensityPositive displacement pump componentsPiston pumpsInlet channelLinear compressor

The invention relates to a reciprocating-piston type oil-less air compressor. In the invention, a piston of a compressor is fastened with a connecting rod or integrally manufactured with the connecting rod; and the piston is arranged in an air cylinder and reciprocates and swings relative to the air cylinder. The reciprocating-piston type oil-less air compressor is characterized in that: the air cylinder adopts an offset structure, which means the axial line of the air cylinder is not intersected with the axial line of a crankshaft, so the offset angle of the piston relative to the air cylinder is reduced in the compression stroke, and the lateral pressure and panting strength of the piston on the air cylinder and the abrasion loss of a sealing ring or a sealing rubber cup are reduced; besides, the oval deformation of the sealing ring or the sealing rubber cup is reduced, so the fatigue state thereof is relieved and the screech which is generated by the leakage at an oval gap and the escape of gas is reduced; and moreover, structures such as a closed crankcase structure, a crankcase air inlet soundproofing chamber, an air inlet channel and the like are adopted for effectively reducing the induction noise and the induction jetting noise and an exhaust soundproofing housing is adopted for reducing the exhaust noise, so the reciprocating-piston type oil-less air compressor can be used for manufacturing the air compressor, an air pump, a vacuum pump or a fluid pump.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

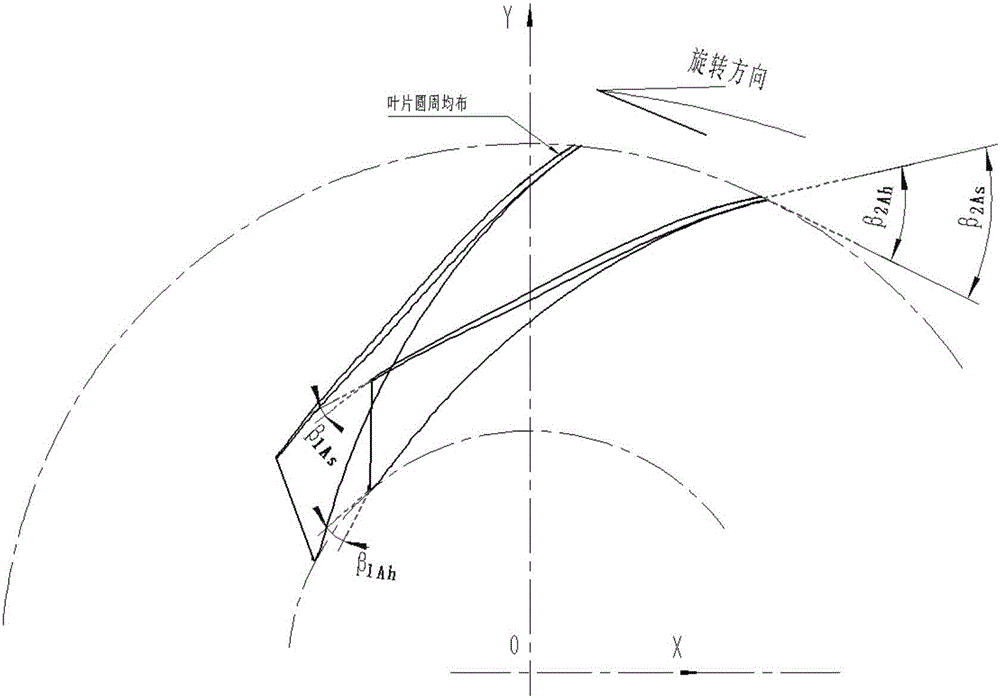

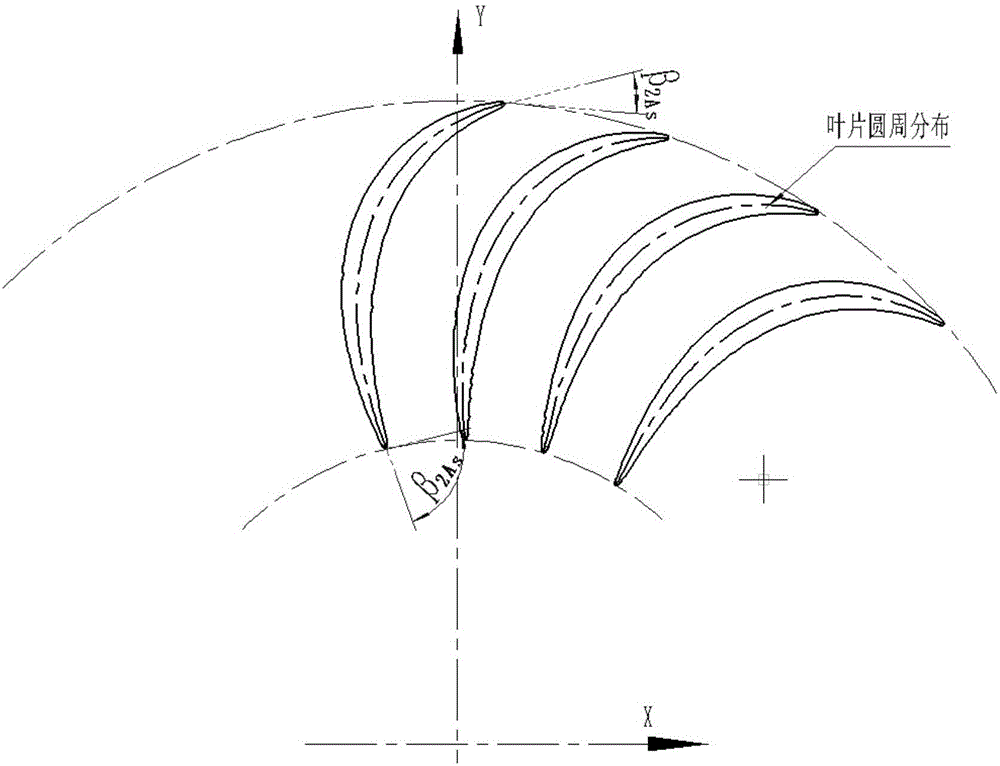

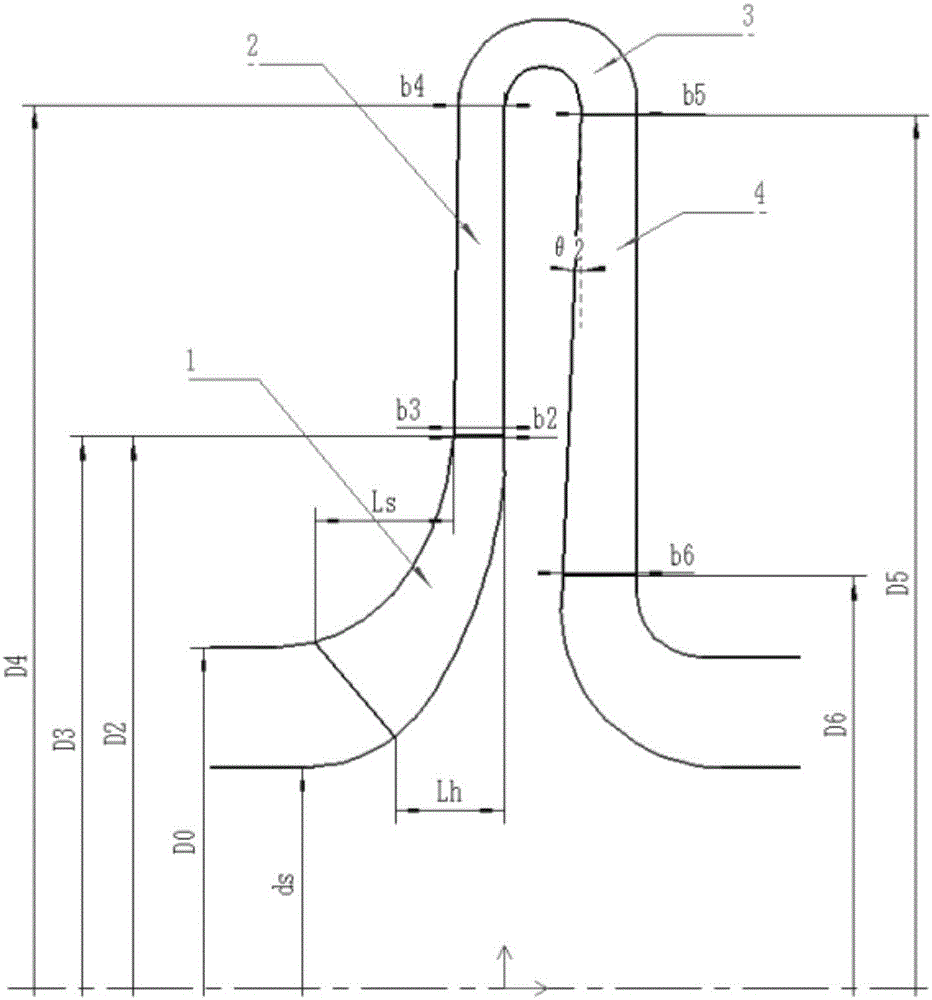

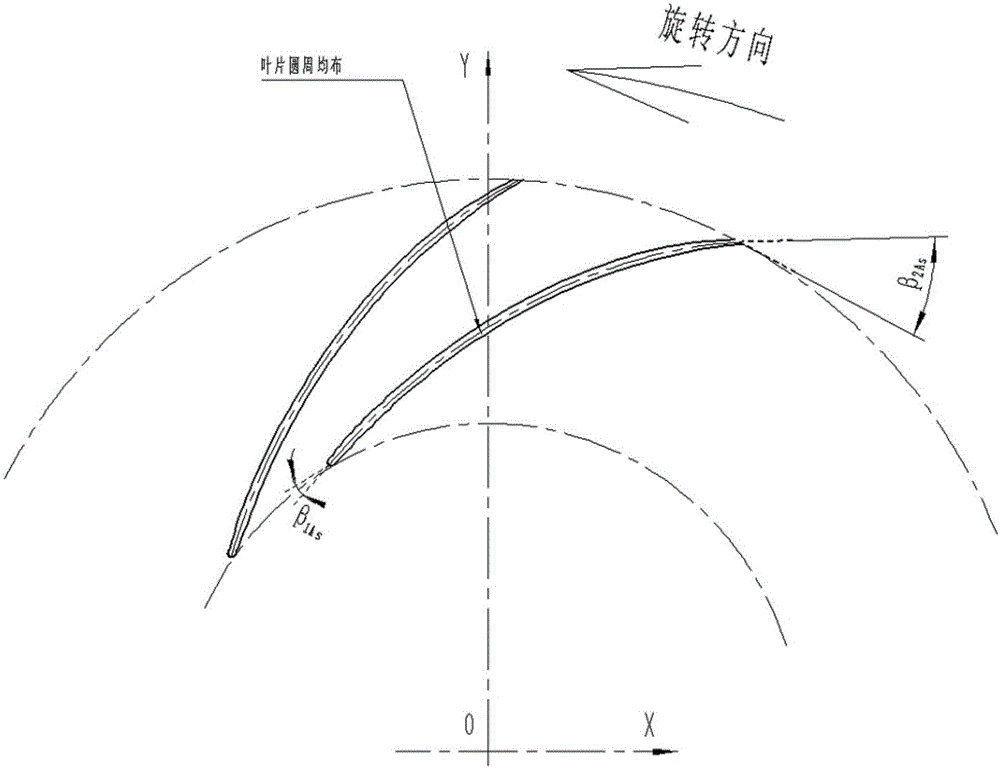

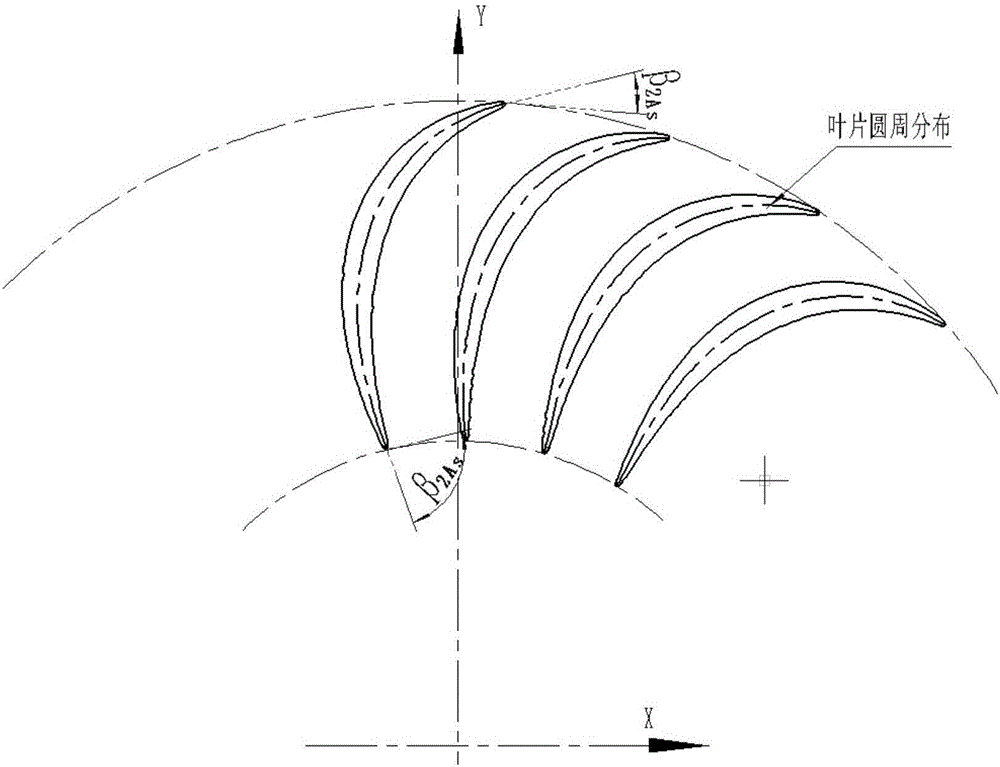

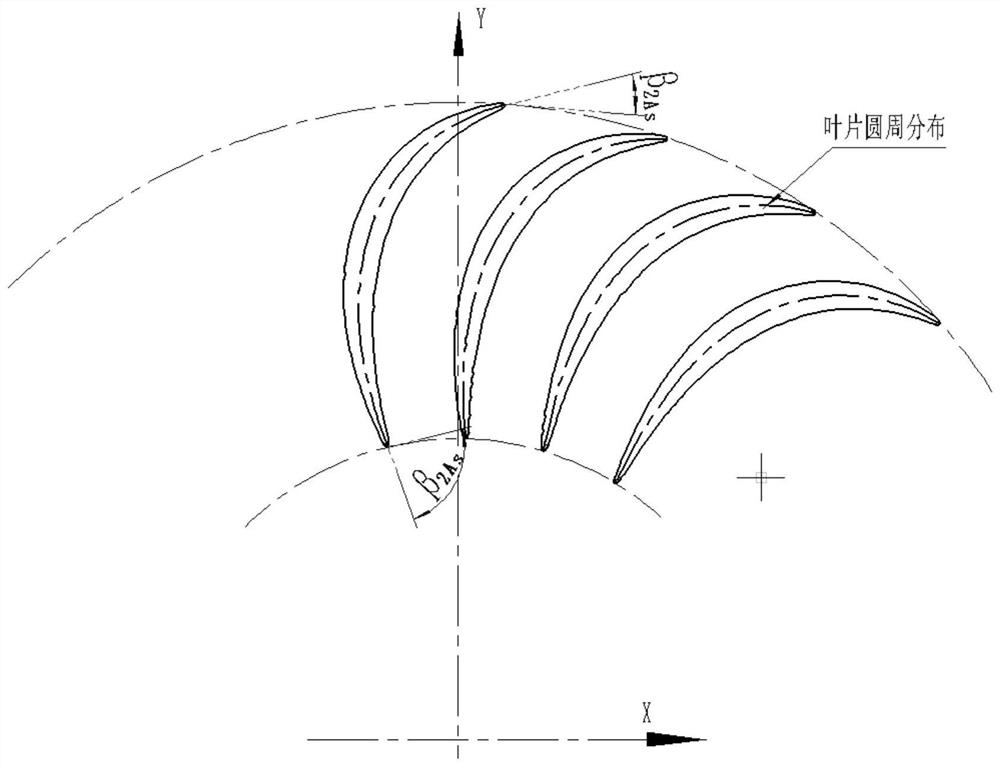

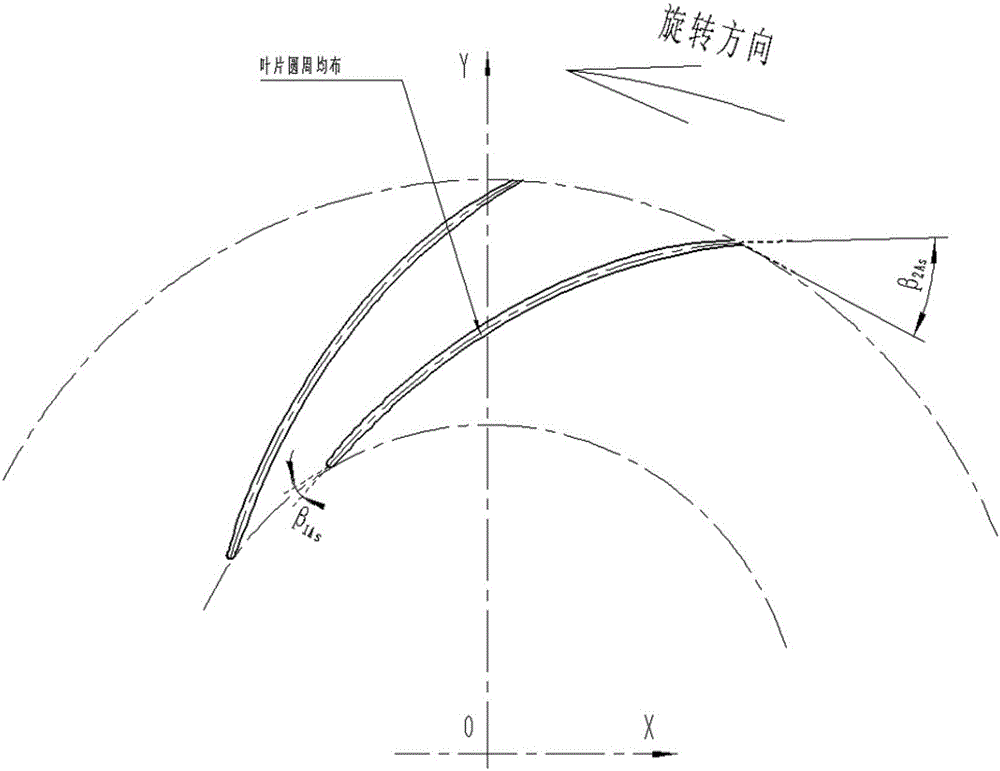

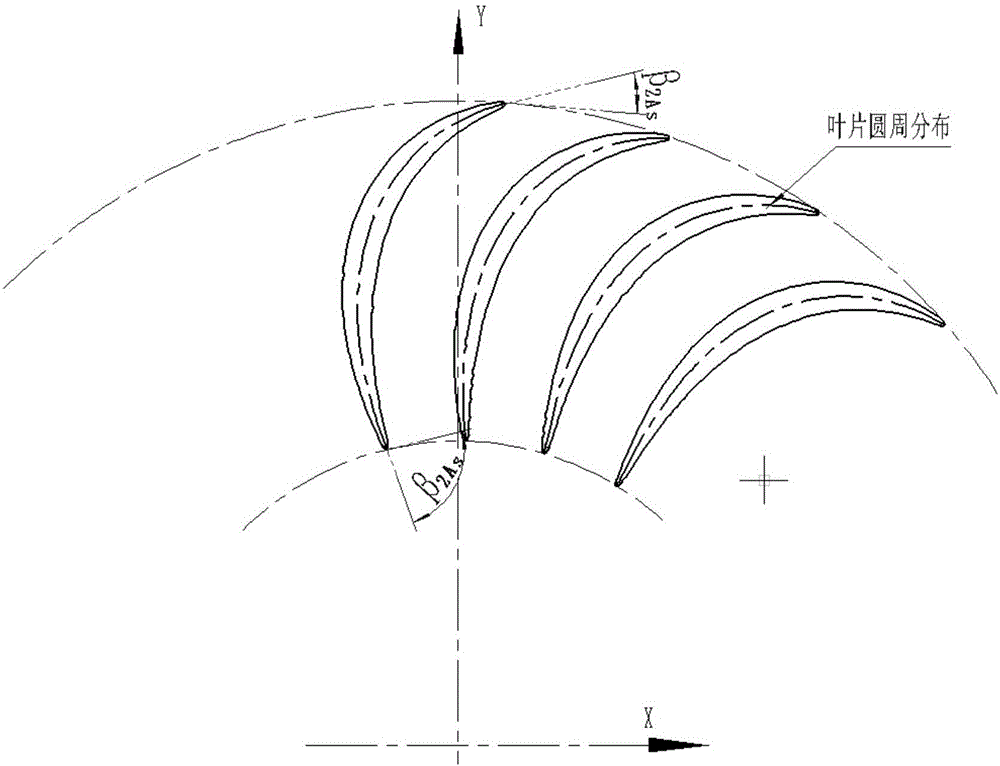

Pipeline compressor model stage with flow coefficient of 0.0495 and impeller design method

InactiveCN106762811AHigh head coefficientWheel hub ratioPump componentsDesign optimisation/simulationImpellerEngineering

Owner:SHENYANG TURBO MASCH CORP +1

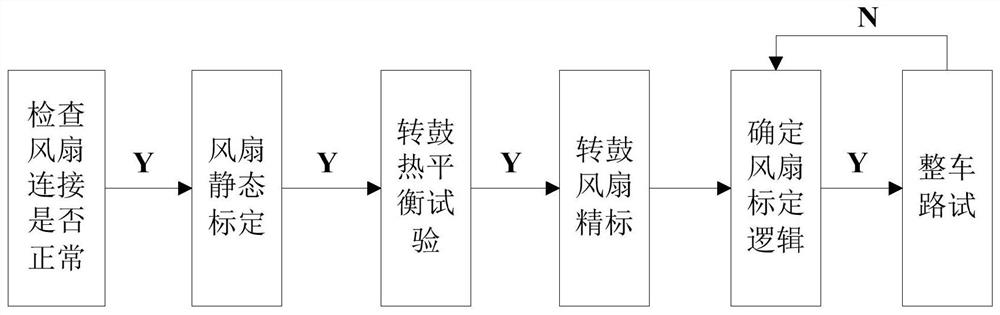

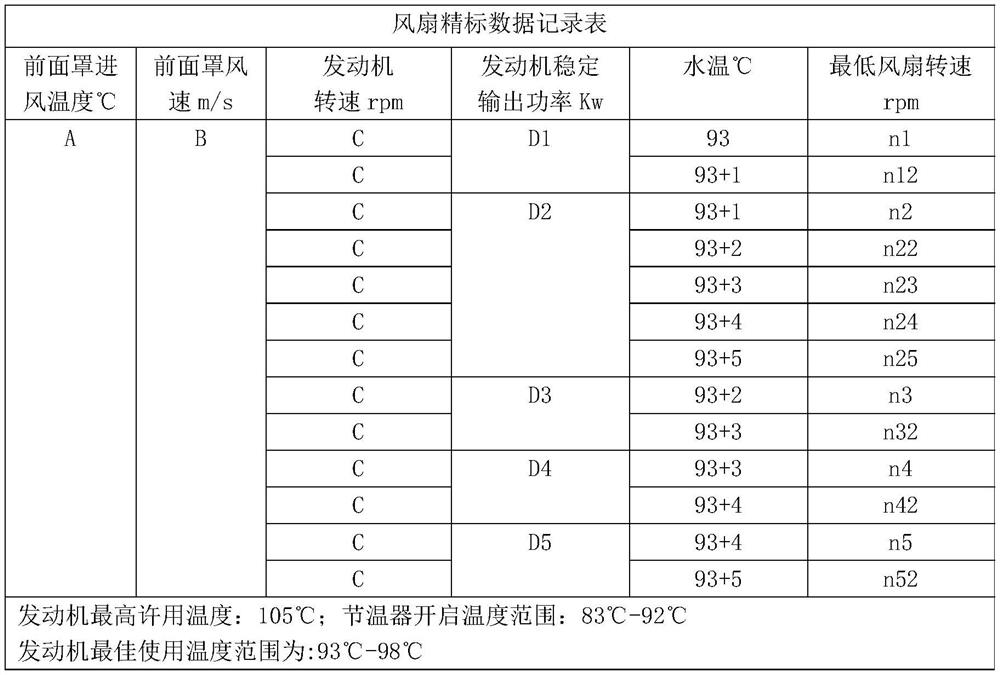

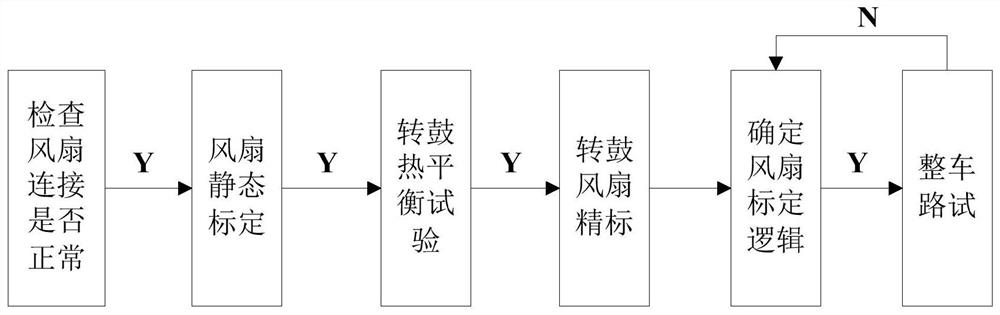

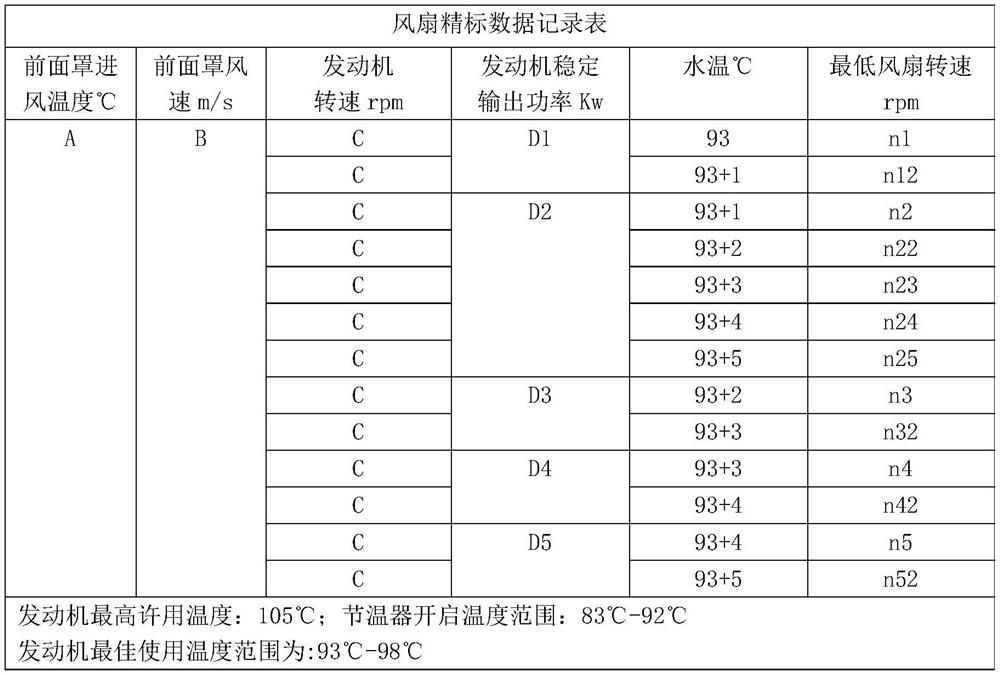

Heavy-duty automobile electric control silicone oil clutch fan calibration method

ActiveCN111608786AReduce working speedTo save fuelVehicle testingCoolant flow controlElectric controlControl theory

The invention discloses a heavy-duty automobile electric control silicone oil clutch fan calibration method. The method comprises the following steps of 1, testing whether the water outlet temperatureof an engine exceeds the highest water outlet temperature allowed by engine design when the engine is under the limit load and a fan is at the limit rotating speed, and if so, replacing a fan with higher power; 2, recording the rotating speed corresponding to the fan when the water outlet temperature of the engine is maintained in the optimal use water temperature range under the conditions of constant rotating speed of the engine and different output powers of the engine; and 3, when a vehicle actually runs and the water temperature of the engine is changed within the optimal use water temperature range under the output power in the step 2, enabling the fan to run at the corresponding rotating speed measured in the step 2. On the premise of ensuring that the engine is not overheated under the limit load working condition, the engine under the common working condition of the whole vehicle is maintained within the optimal working water temperature, air temperature and engine oil temperature range, and meanwhile, the lowest working speed of the fan is ensured, so that the purposes of oil saving and noise reduction are achieved.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

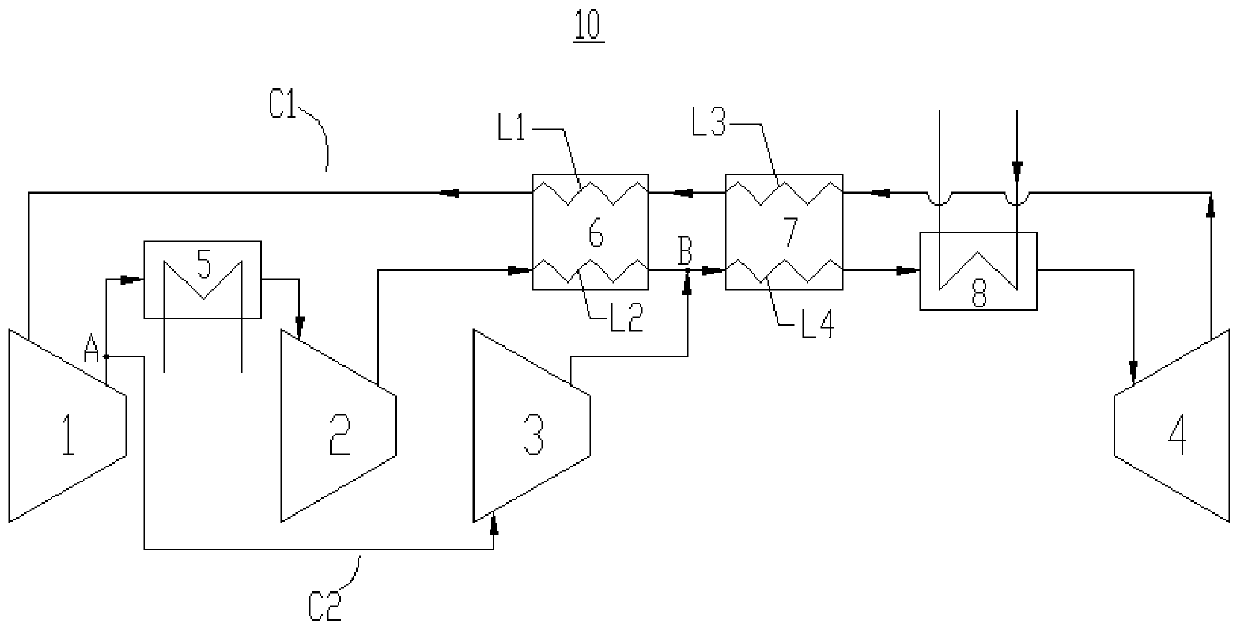

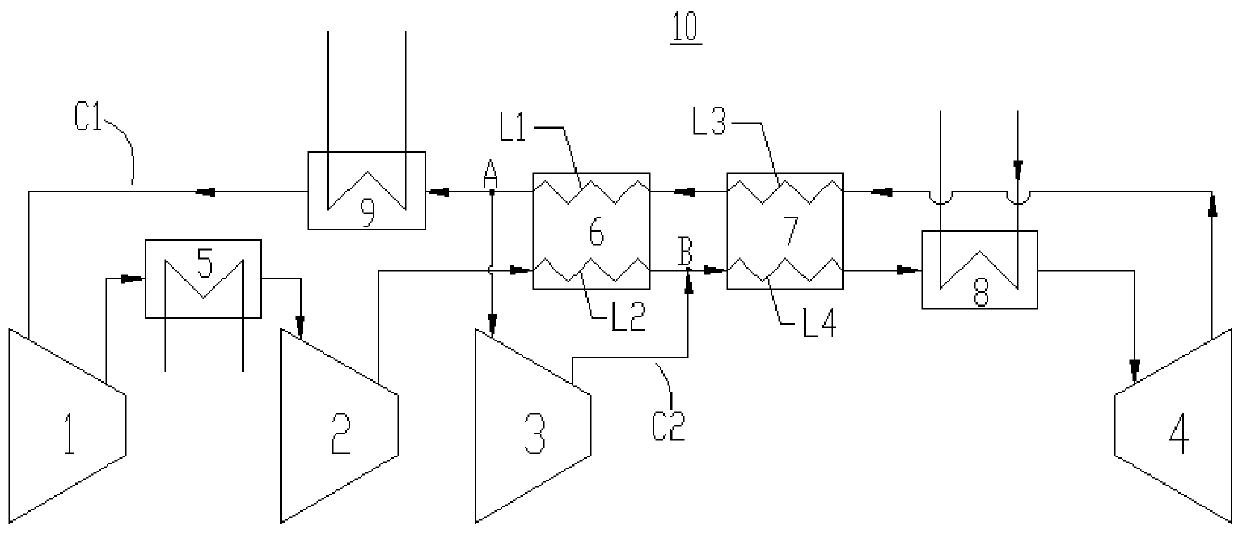

Transcritical CO2 closed circulation system

PendingCN110966058AImprove cycle efficiencyAvoid running unstableSteam engine plantsEngineeringElectrical drive

The invention belongs to the field of energy conversion, provides a transcritical CO2 closed circulation system and aims at solving the problems of narrow operation range and low circulation efficiency of an existing transcritical CO2 power generation / driving unit. The system comprises a pre-compressor, a main compressor, a re-compressor, a turbine, a cooler, a low-temperature heat regenerator, ahigh-temperature heat regenerator and a heater; the pre-compressor, the main compressor, the re-compressor, the turbine, the cooler, the low-temperature heat regenerator, the high-temperature heat regenerator and the heater are connected to form a closed CO2 circulation loop; a shunting point and a mixing point are arranged on the closed CO2 circulation loop. The inlet of the re-compressor is communicated with the shunting point; the outlet of the re-compressor is communicated with the mixing point; and therefore, a shunting branch is formed; and the shunting branch is shunted out of the outlet of a first channel and converged at the outlet of a second channel. The system has high circulation efficiency. With the system adopted, the operation range of the unit is wide.

Owner:DONGFANG TURBINE CO LTD

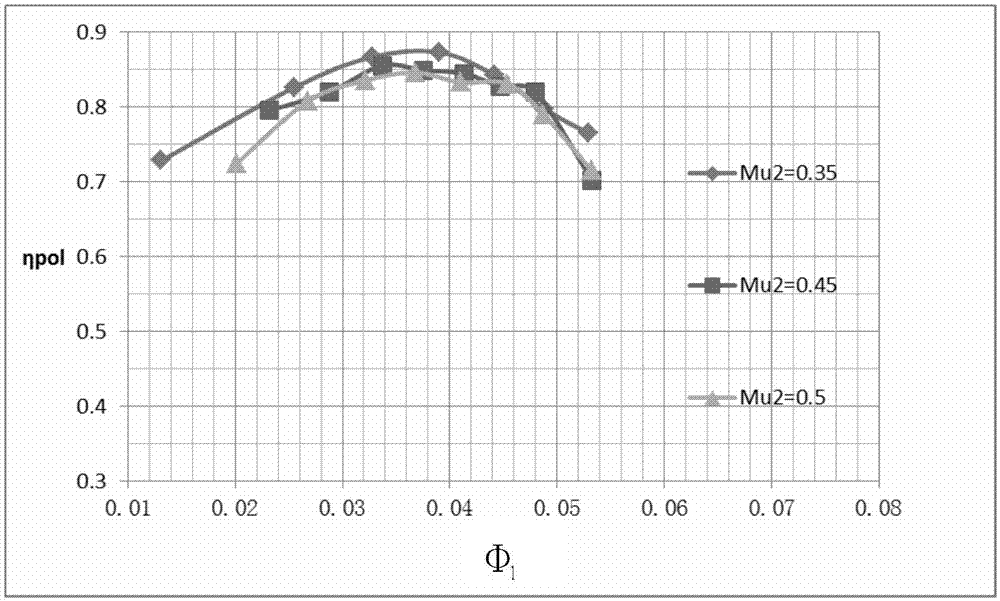

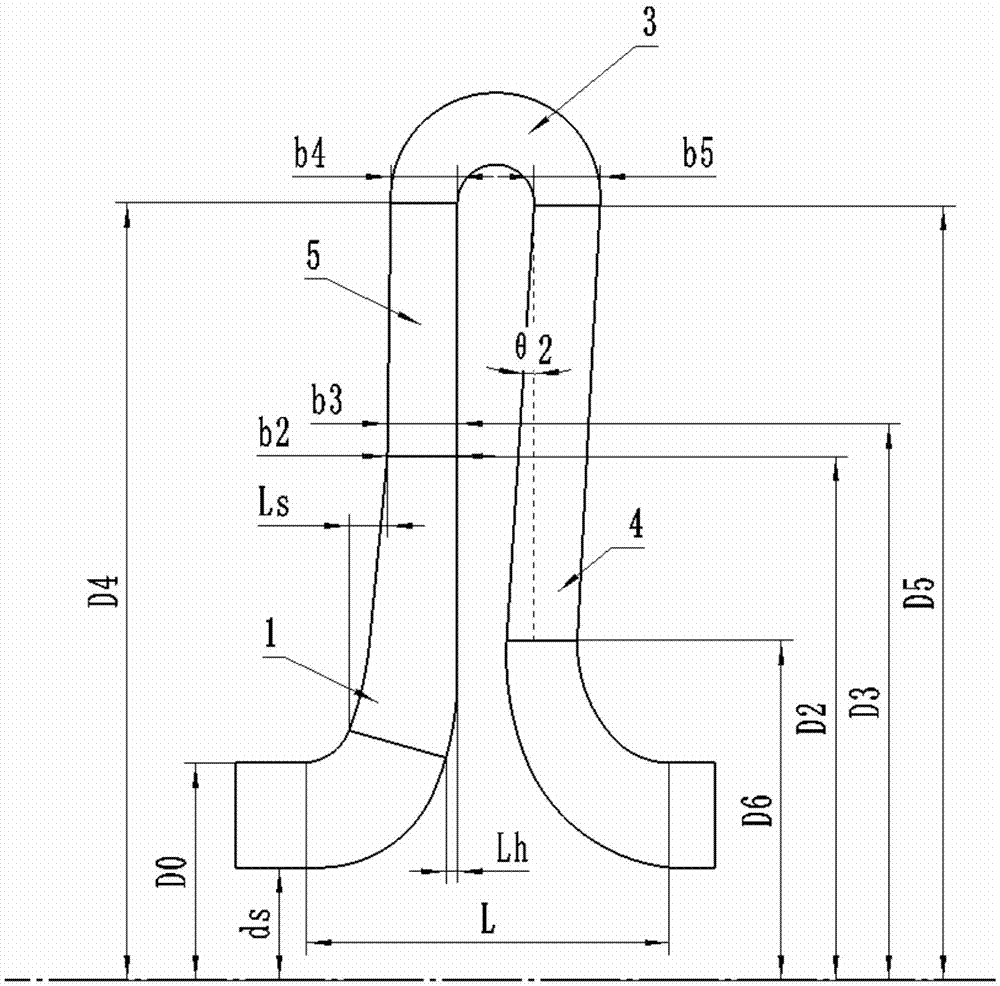

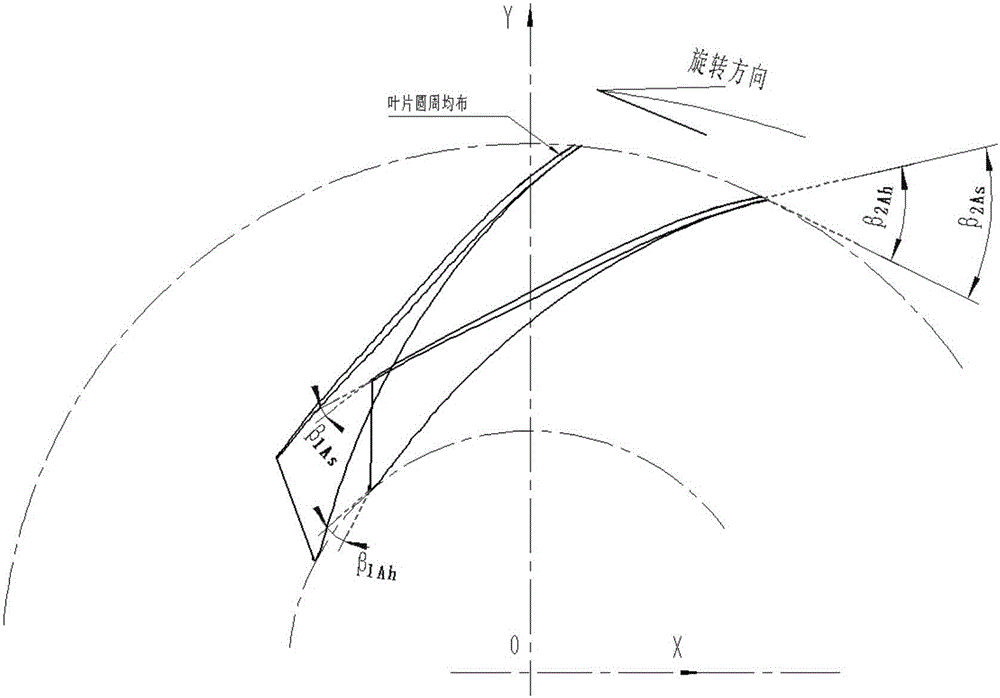

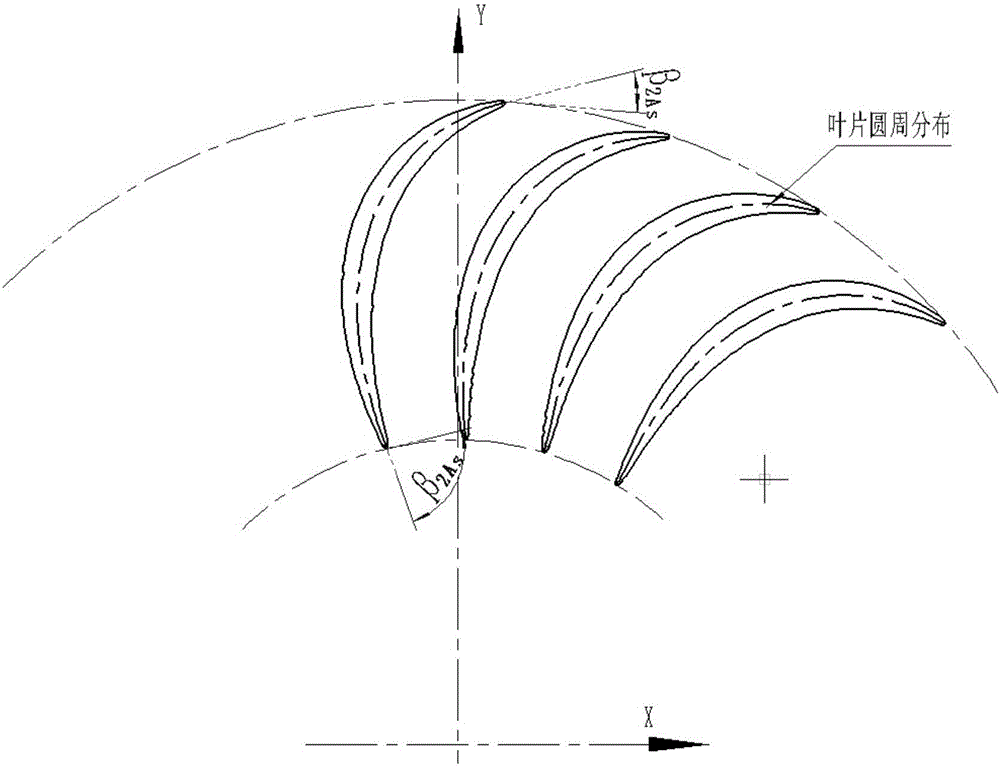

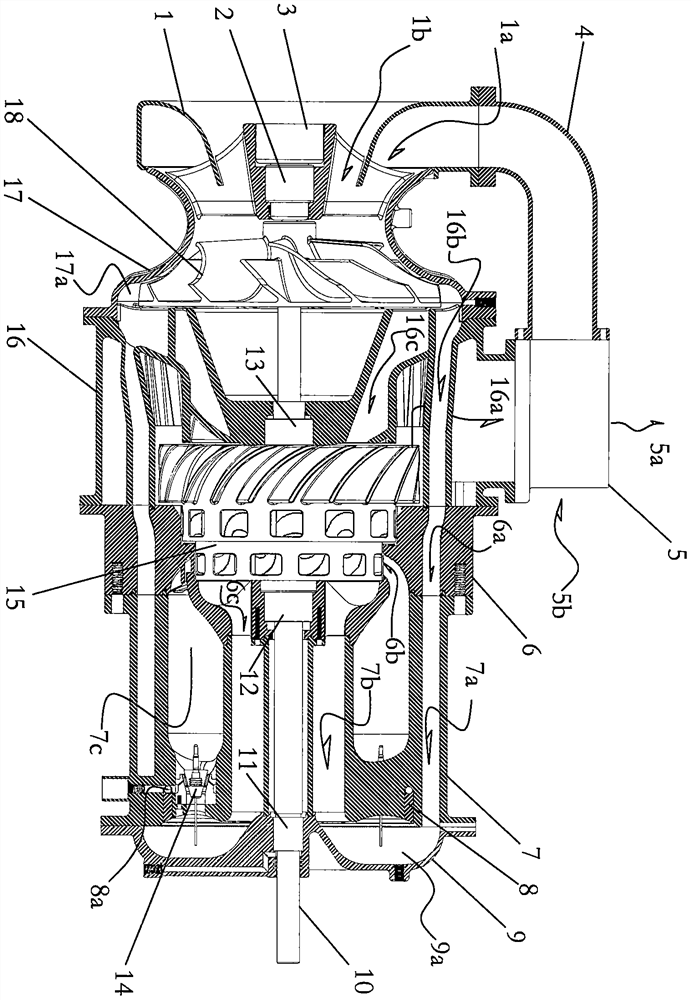

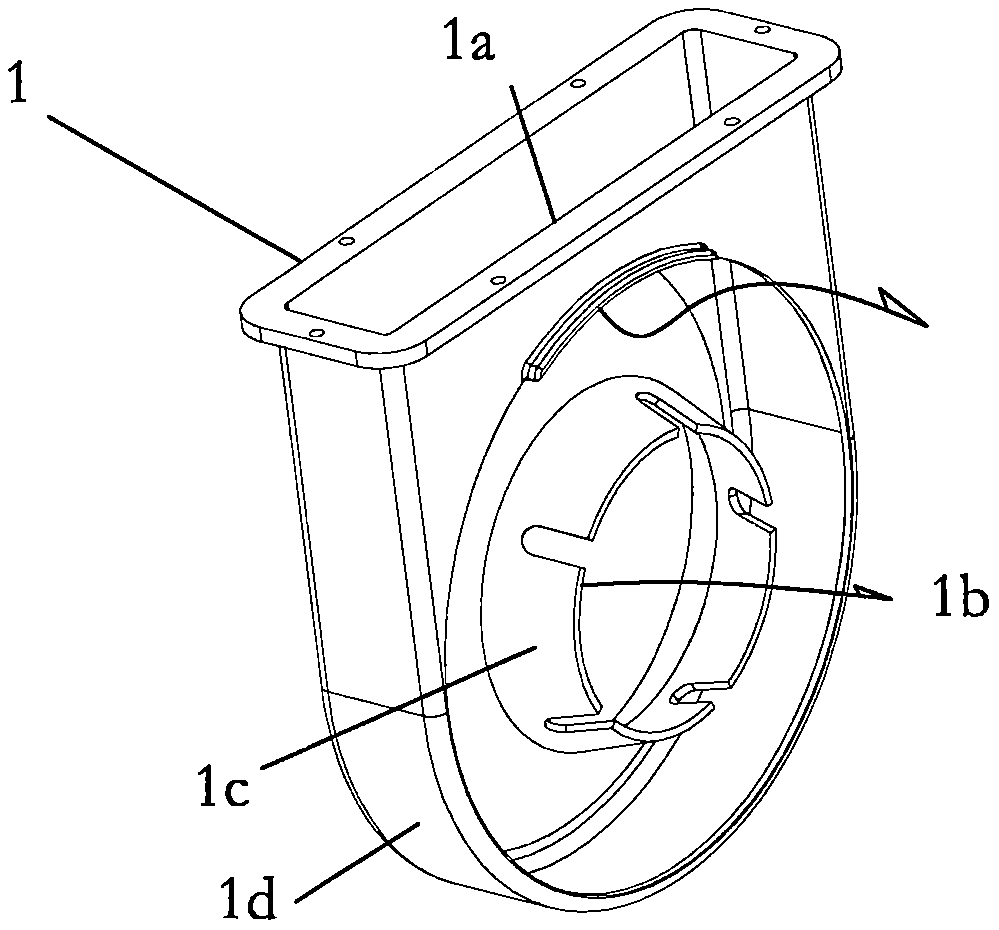

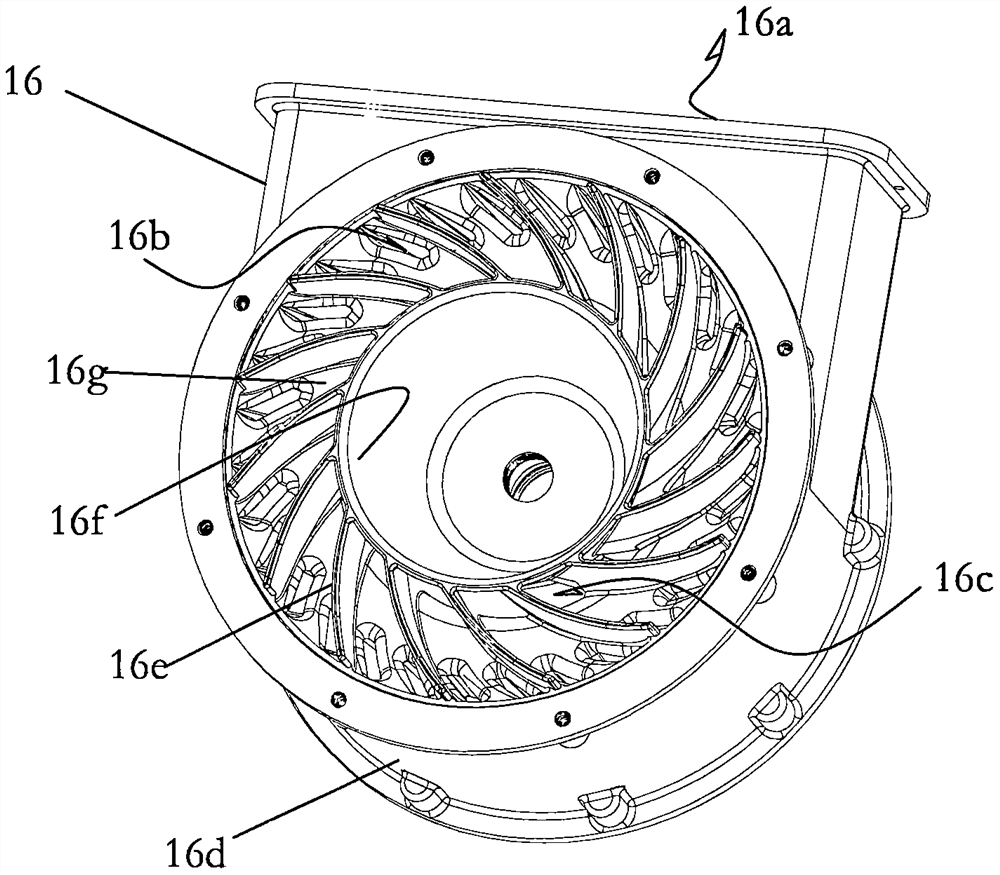

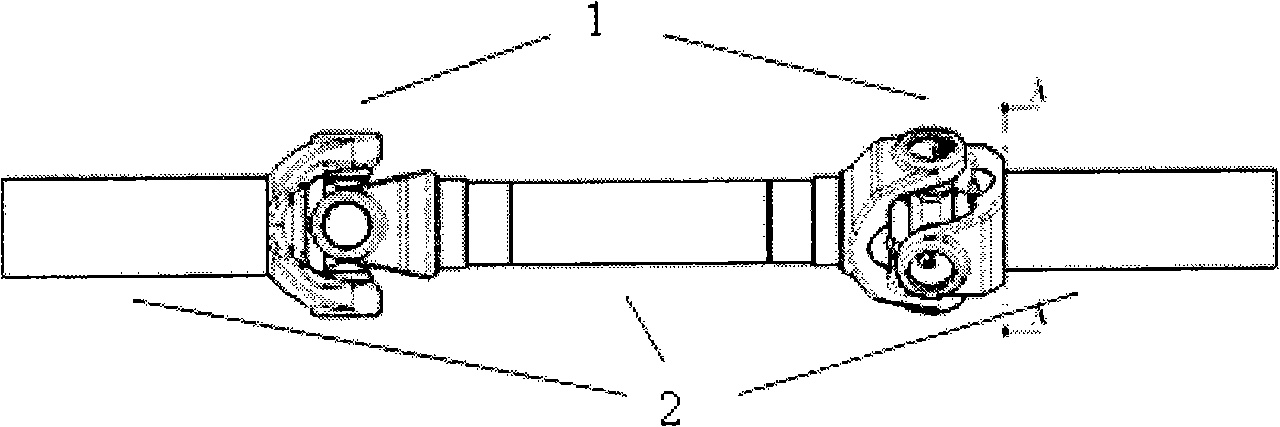

Model stage special for pipeline compressor

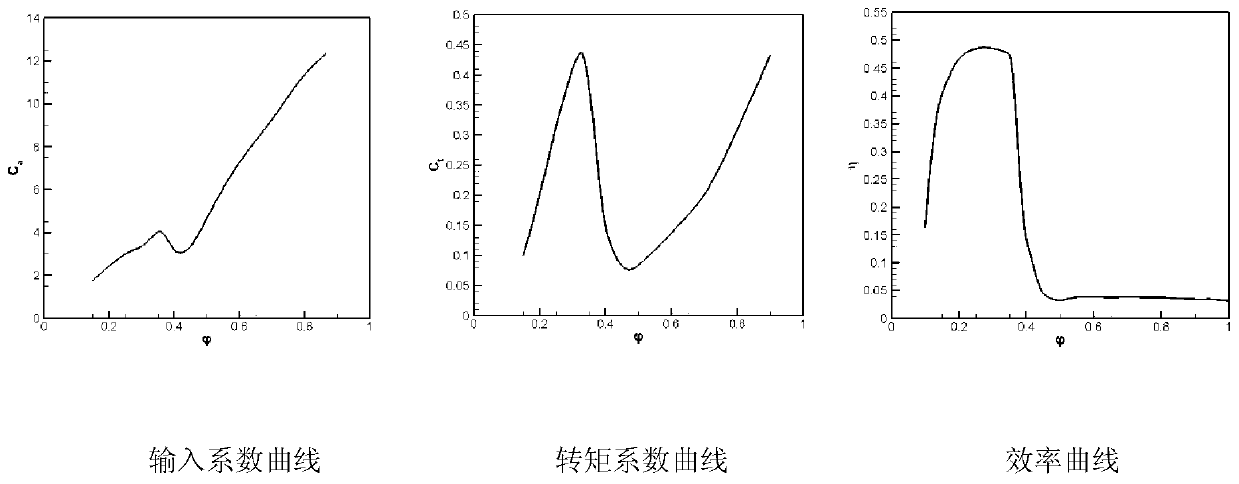

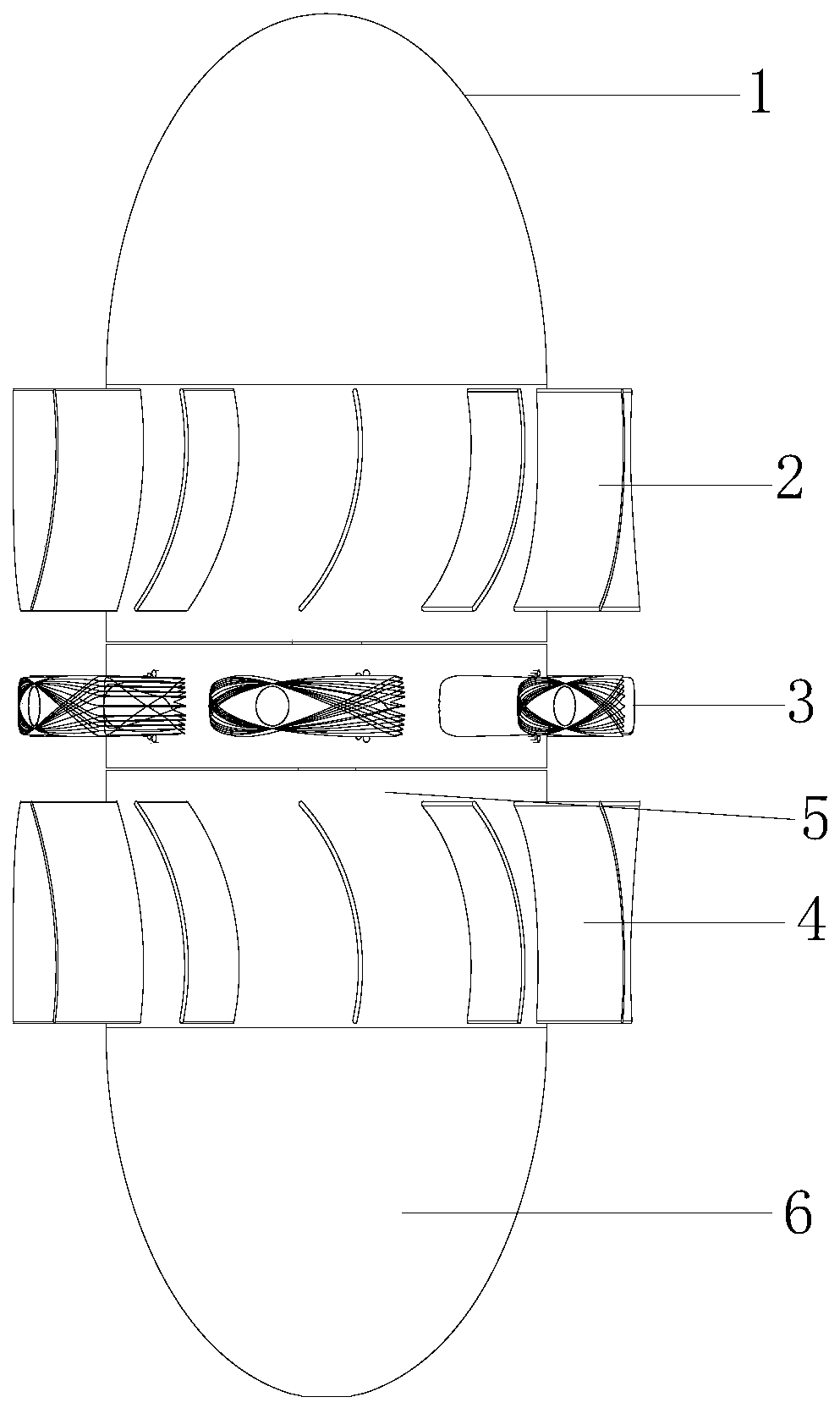

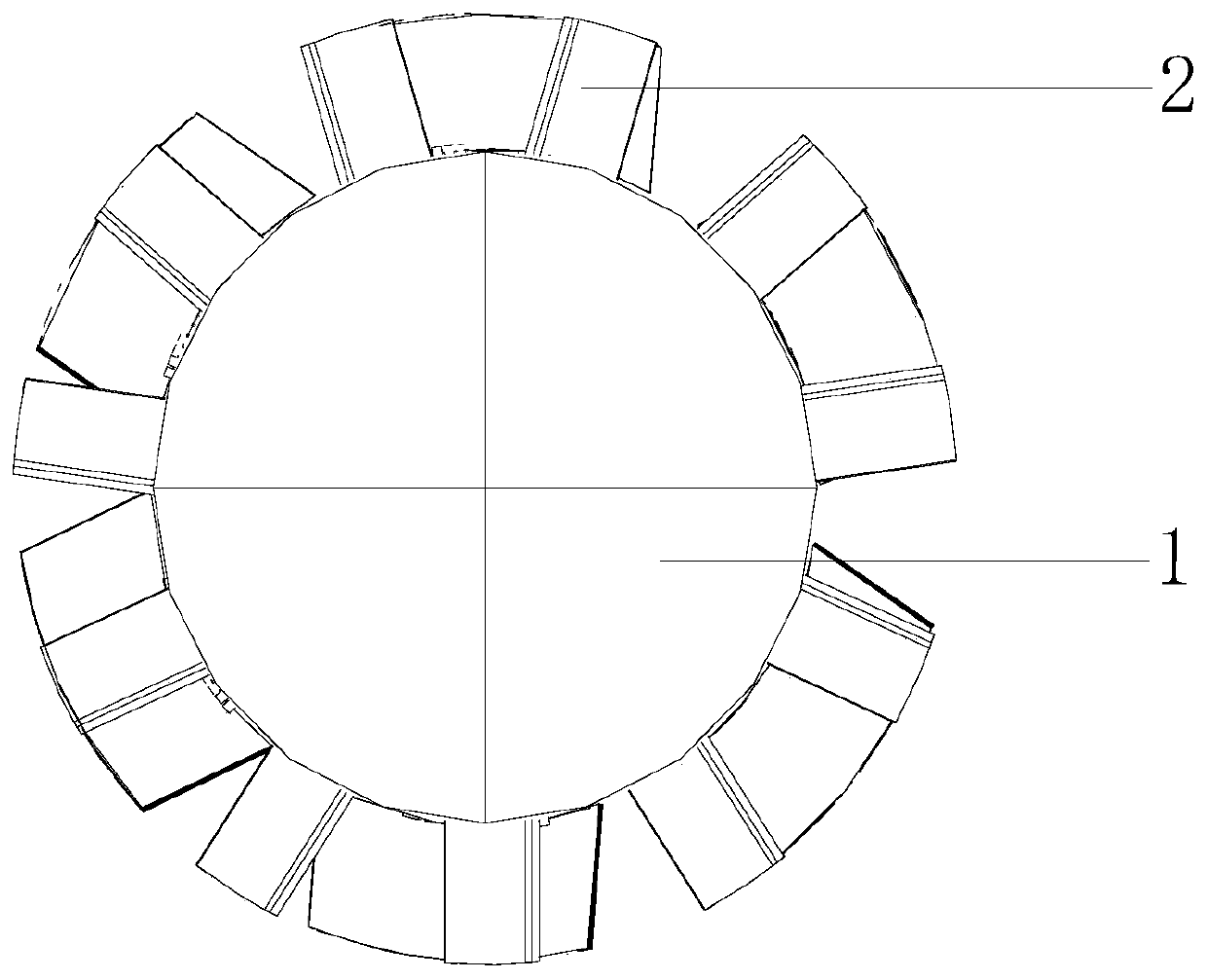

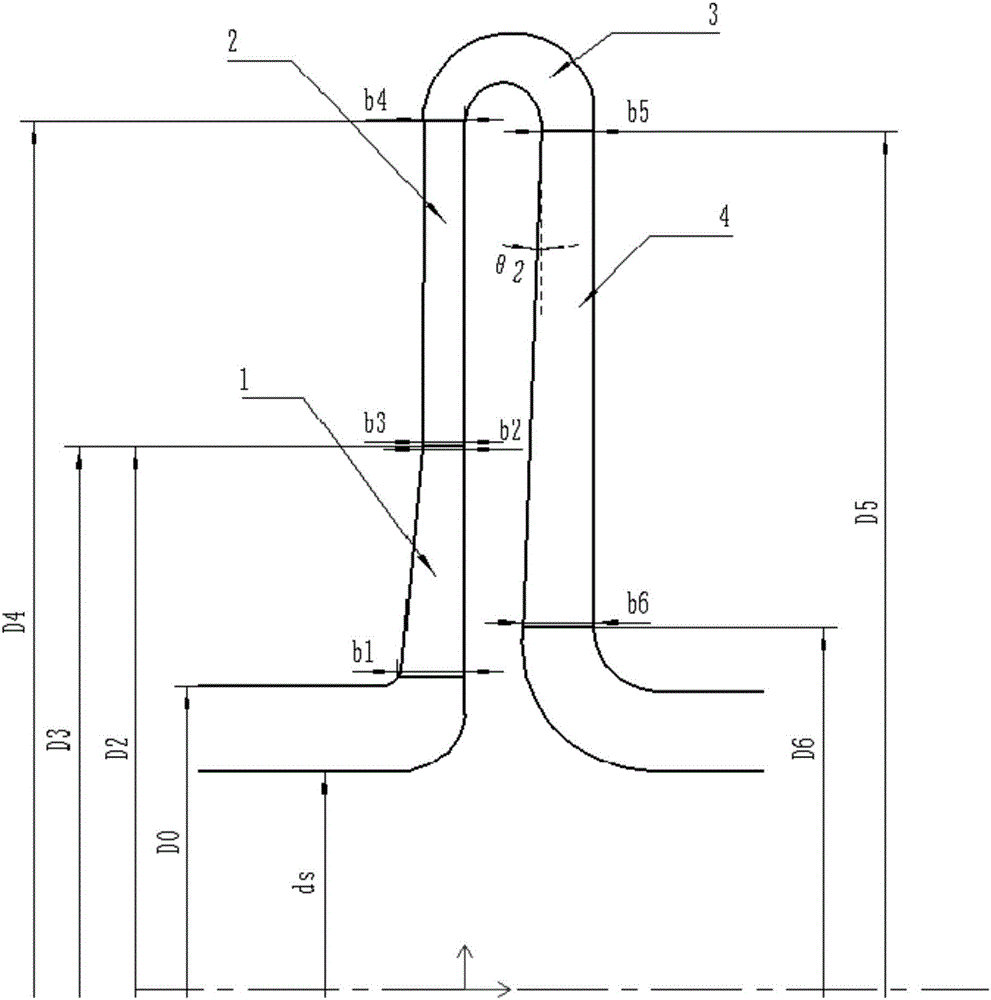

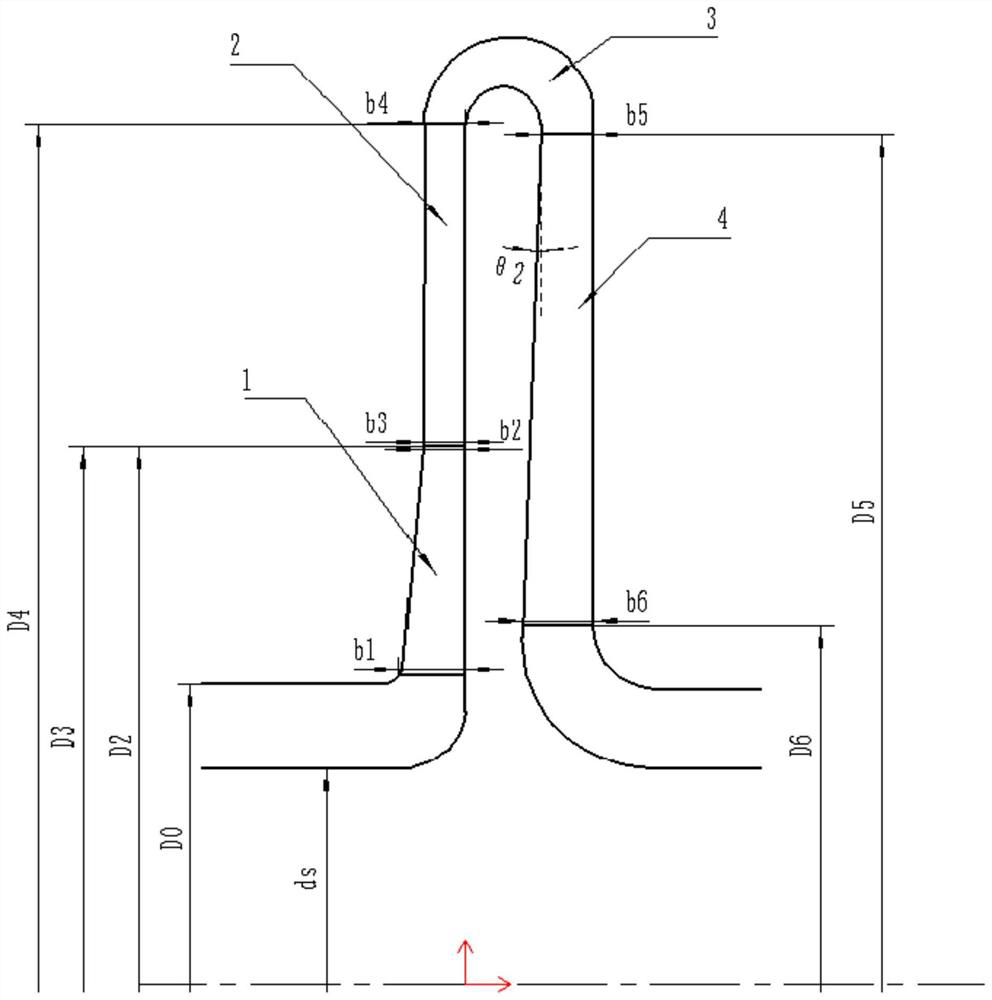

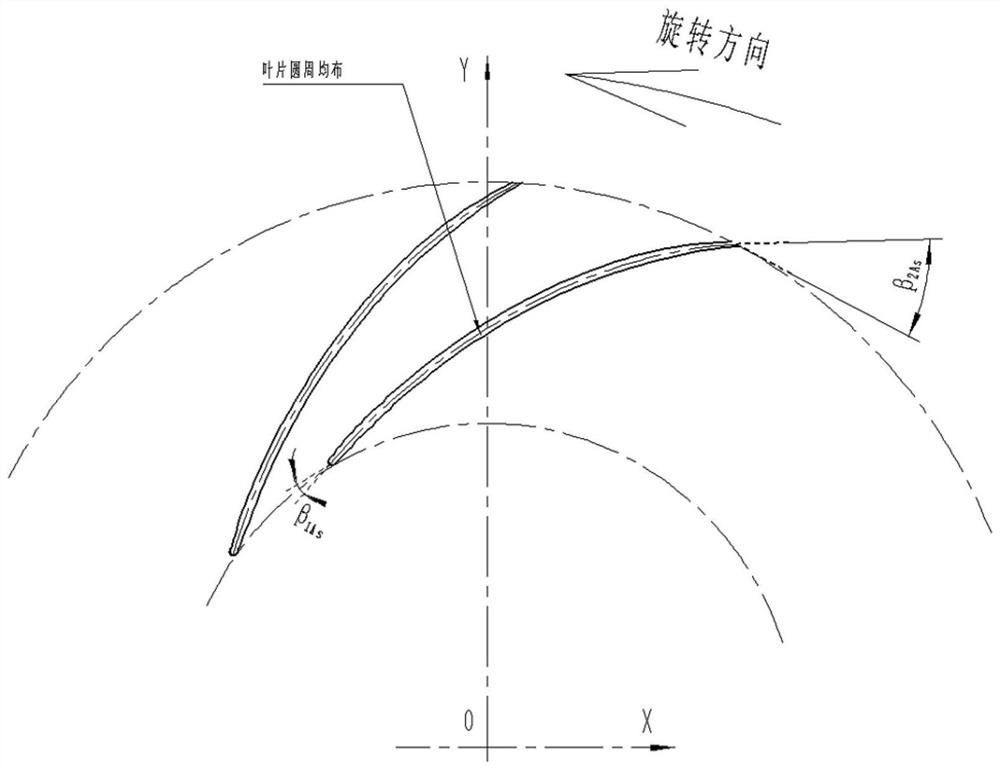

InactiveCN106870447AHigh variable efficiencyHigh head coefficientPump componentsPumpsCentrifugal compressorStreamflow

The invention belongs to a centrifugal compressor model stage, and particularly relates to a model stage special for a pipeline compressor. The model stage is suitable for modeling design of a pipeline compressor product. The model stage comprises an impeller, a vaneless diffuser, a curve and a backflow device; the impeller is located at the inlet position of the model stage, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is located at the outlet position of the model stage, and the vaneless diffuser is communicated with the backflow device through the bend; and the design machine mach number Mu2 of the model stage is 0.35 to 0.5, the flow coefficient phi1 is equal to 0.023 to 0.053, the energy head coefficient tau is equal to 0.47 to 0.71, the design condition point polytropic efficiency etapol under each mach number is equal to 0.846 to 0.873, the hub ratio ds / D2 of the model stage is equal to 0.4, and the ratio L / D2 of the span to the diameter is 0.292. The model stage is high in efficiency, high in energy head coefficient, large in hub ratio and small in span; by means of the model stage, the pipeline compressor can have the higher running efficiency and wider working condition scope; and meanwhile, the rotor working rotating speed can be decreased, the bearing span is shortened, and the rotor stability is improved.

Owner:SHENYANG BLOWER WORKS GROUP CORP

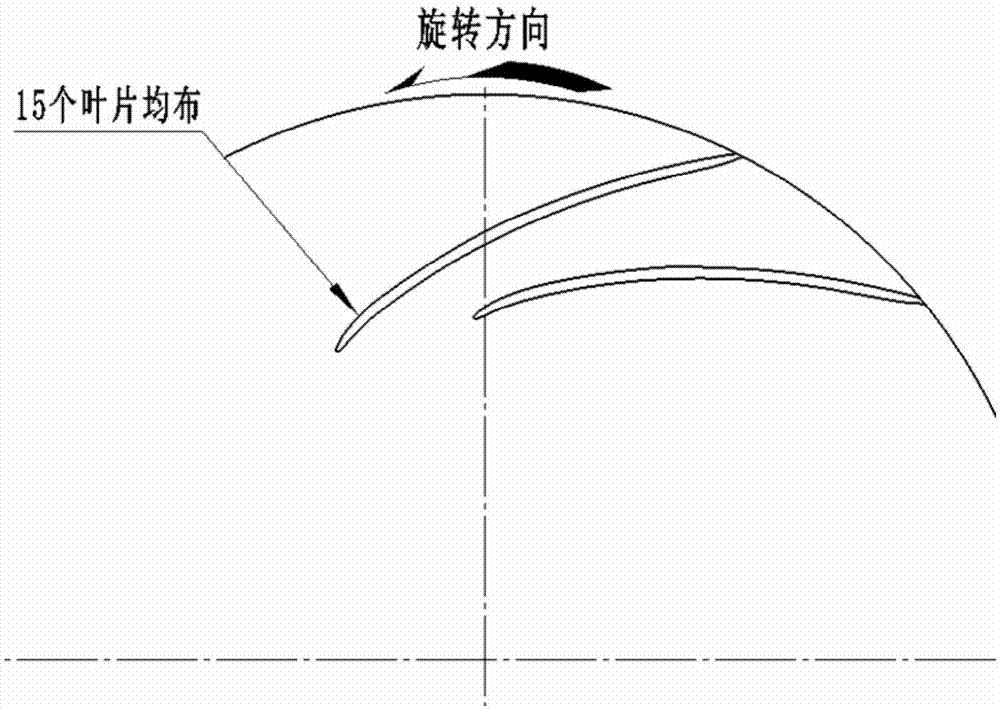

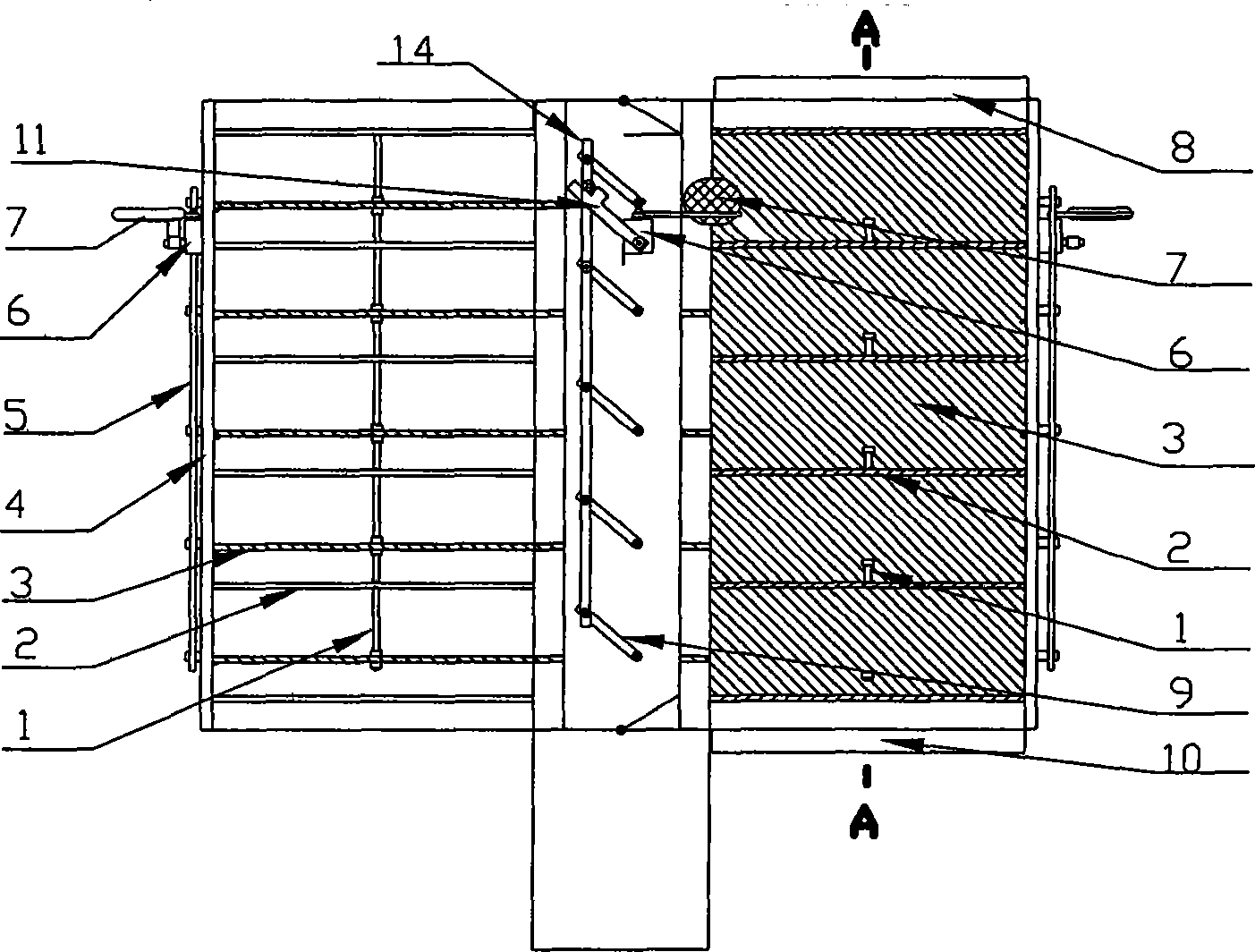

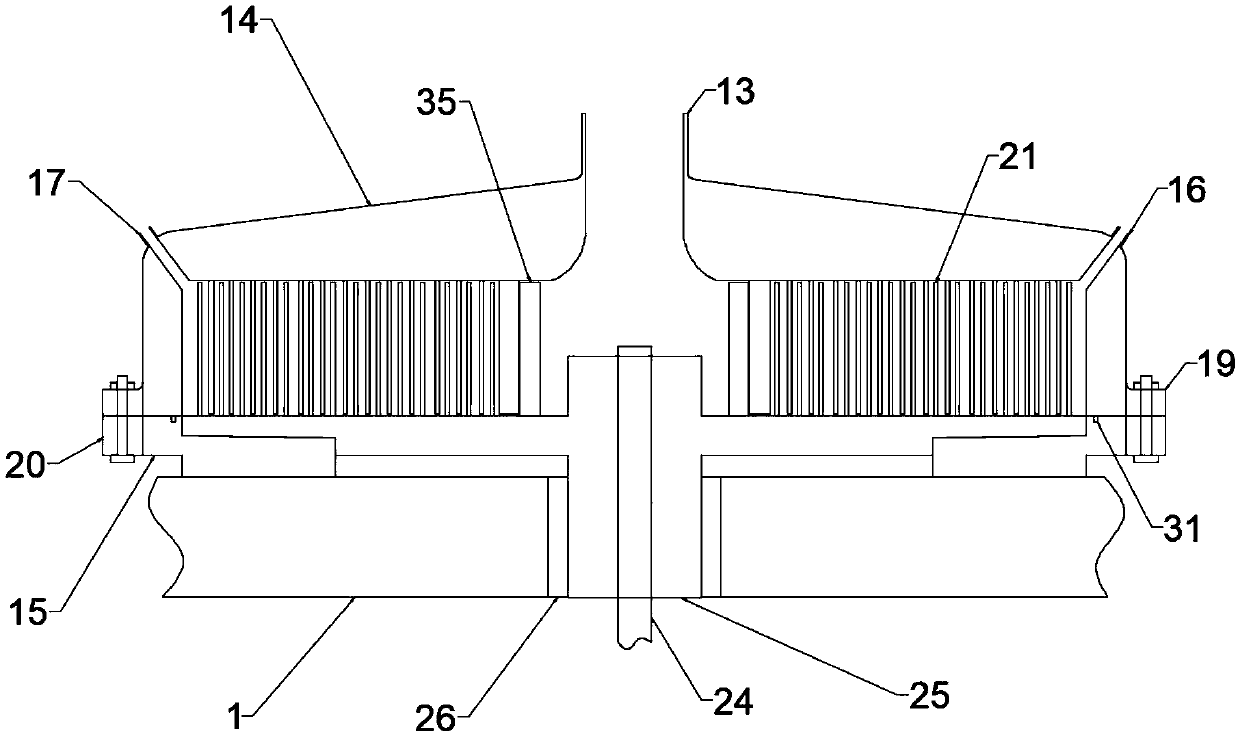

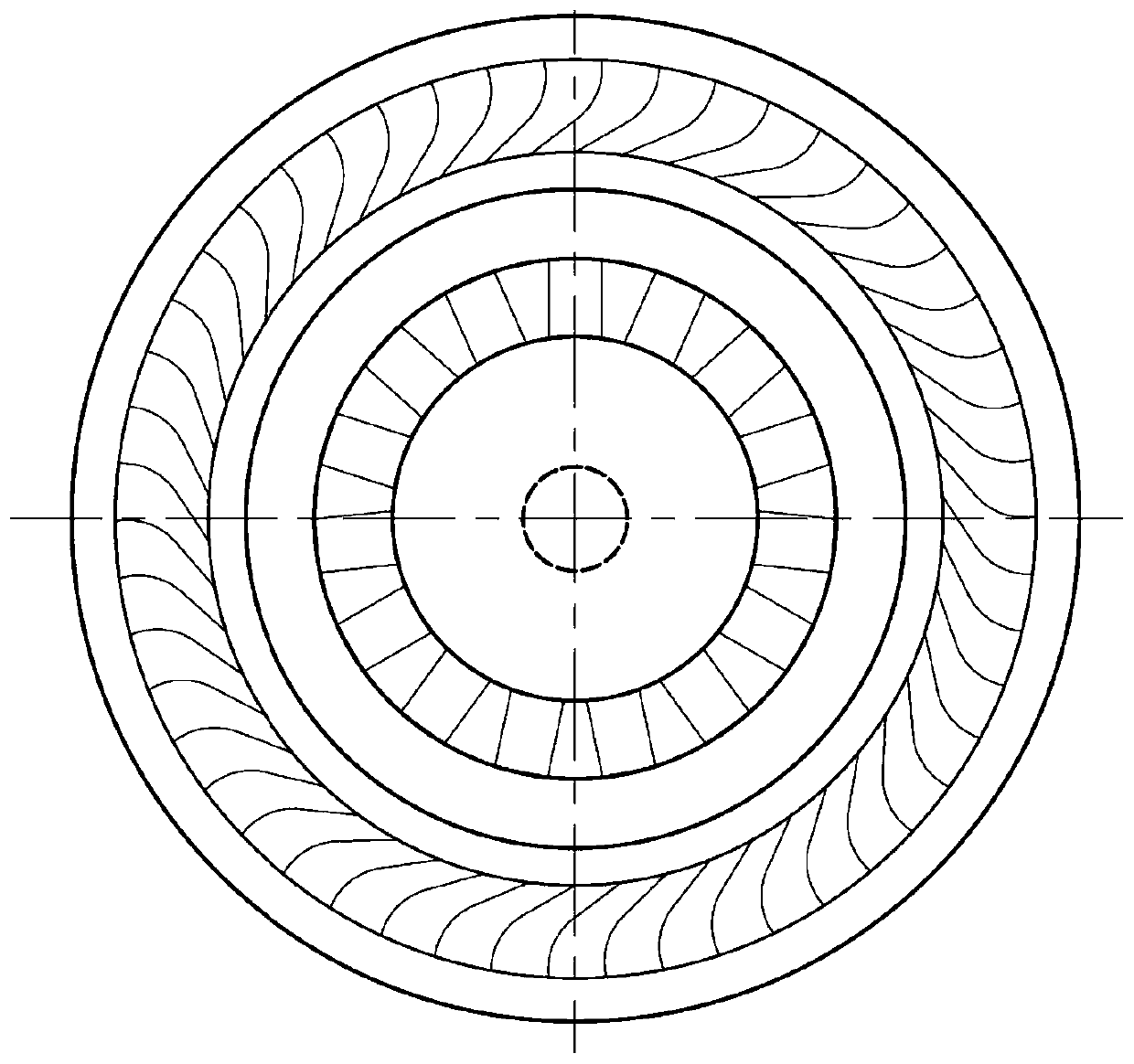

Asymmetric air turbine applicable to Asian sea oscillating water column type wave energy generator

ActiveCN107514290AImprove power utilization efficiencyImprove Cycle Average EfficiencyBlade accessoriesMachines/enginesOscillating Water ColumnEngineering

The invention discloses an asymmetric air turbine applicable to an Asian sea oscillating water column type wave energy generator. The air turbine comprises a hollow hub. Hub heads used for sealing a cavity of the hub are mounted on the two sides of the hub correspondingly. A movable vane wheel capable of rotating around the hub is arranged on the hub. Movable vanes are evenly arranged on the outer wall of the movable vane wheel in the circumferential direction. The vertical section of each vane is in a crescent shape, and the protruding radian of one side of the crescent shape is higher than the protruding radian of the other side of the crescent shape. The two sides of the movable vane wheel are each provided with a circle of flow guiding vanes with the aspect ratio being higher than that of the movable vanes in the circumferential direction of the hub. According to the air turbine disclosed by the invention, the meeting areas of flowing of the pressure faces of the movable vanes at a high incidence flow rate at the exhalation stage can be increased, the flow rate separation phenomenon of airflow on the movable vane suction faces is delayed, power losses caused by air flow entering the downsteam flow guiding vanes from the movable vanes are reduced, the power utilization efficiency of the air turbine at the exhalation stage is improved, and thus the period average efficiency of the air turbine under actual sea conditions is improved.

Owner:OCEAN UNIV OF CHINA

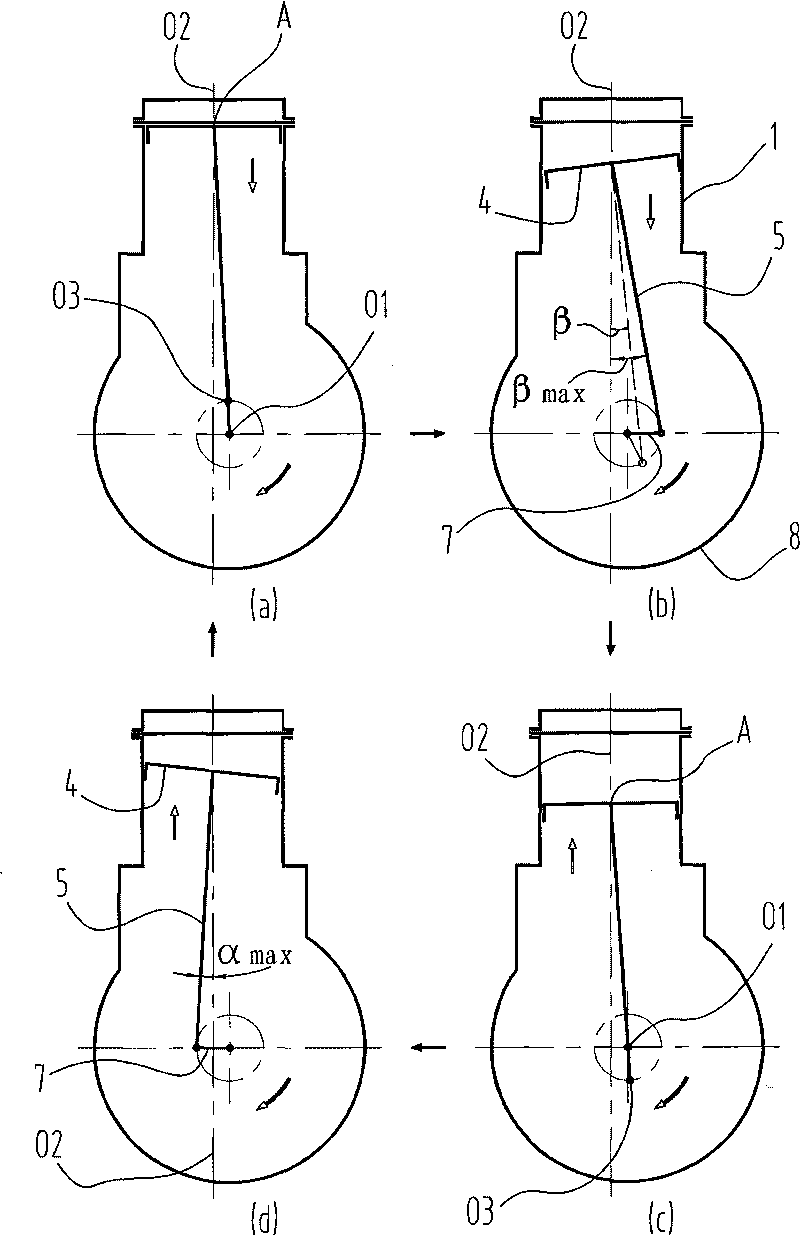

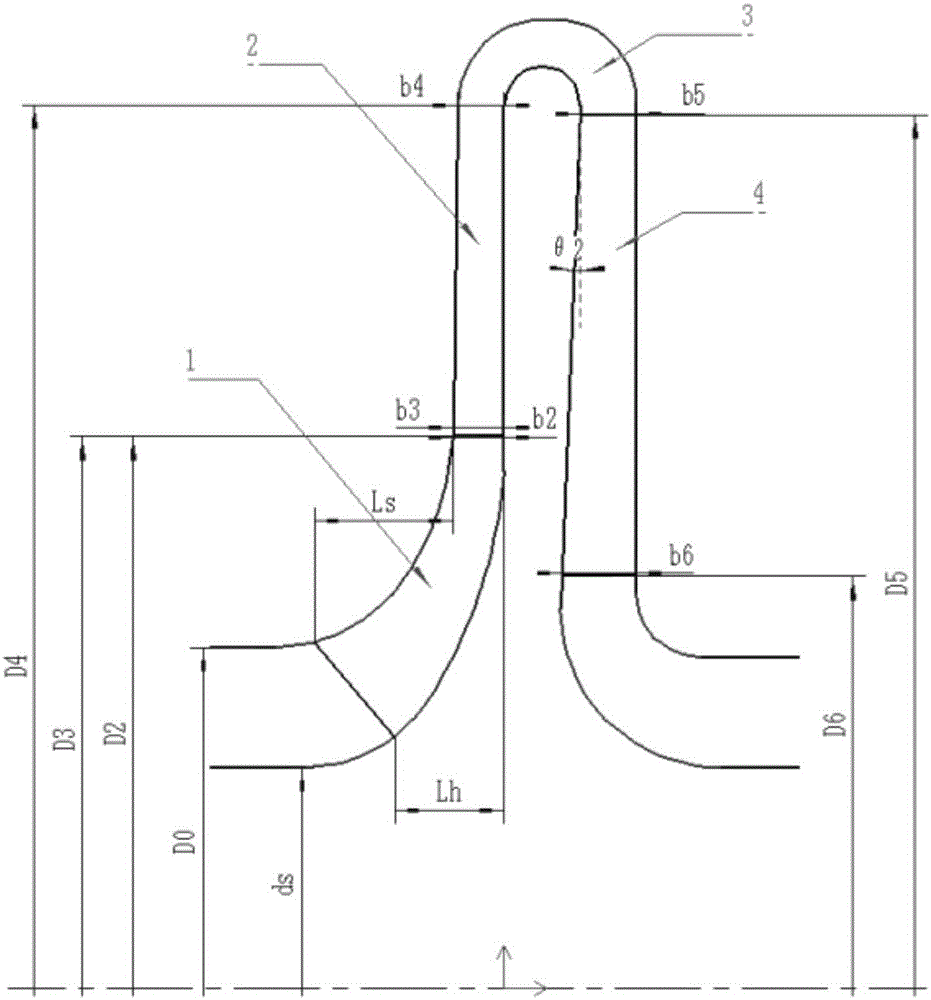

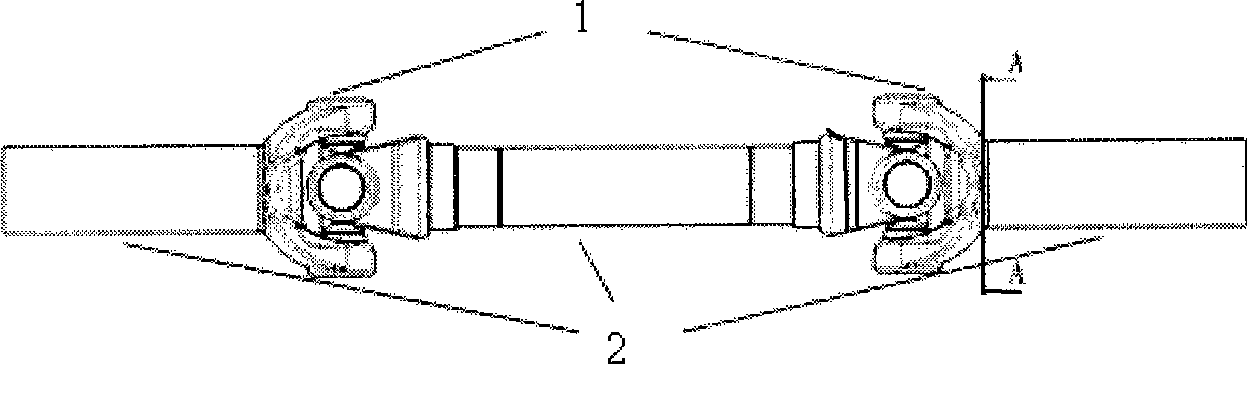

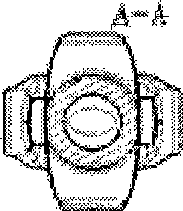

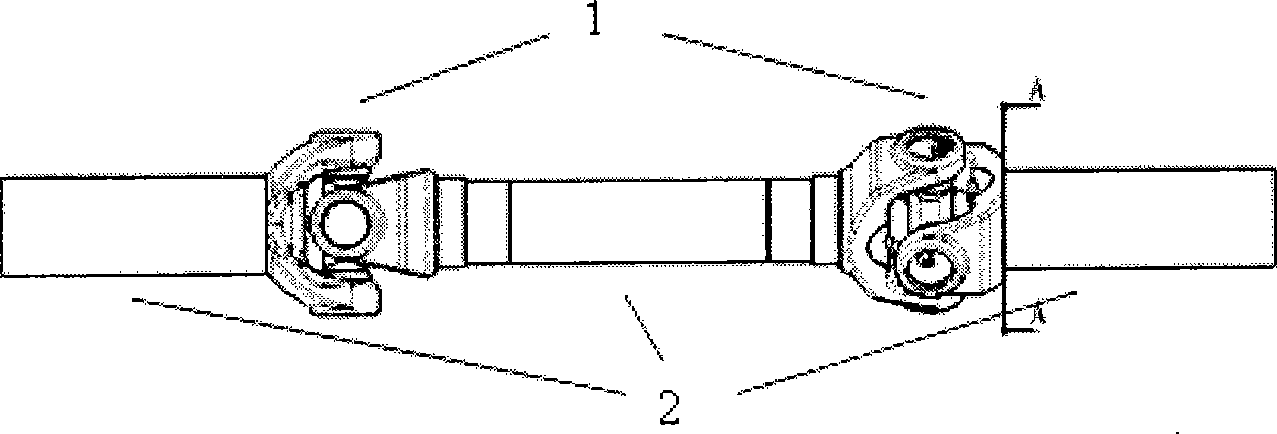

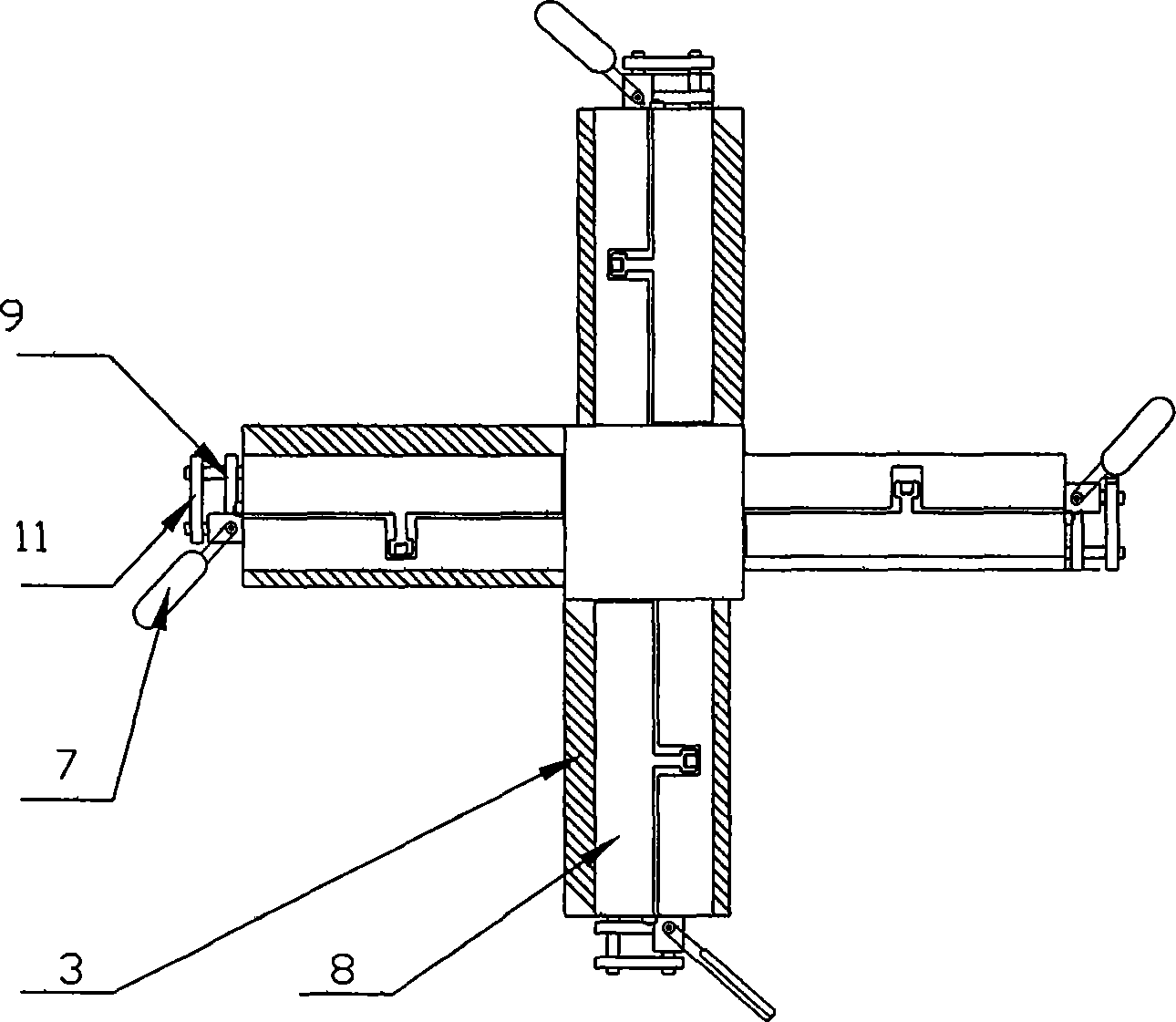

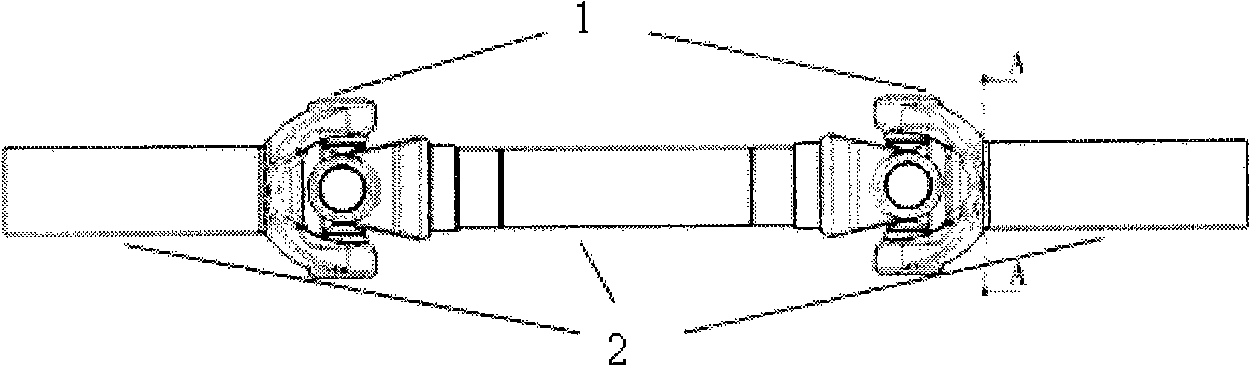

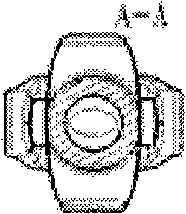

Composite structure of transmission shaft end cross coupling

ActiveCN101440844AReduce vibration amplitudeDo not change angleYielding couplingVibration amplitudeUniversal joint

The invention discloses a combined structure of a transmission shaft end crossed shaft coupling. The combined structure comprises a transmission shaft, wherein both ends of the transmission shaft are connected with crossed shaft type universal joint shaft couplings; and the phase angle theta between the crossed shaft type universal joint shaft couplings is more than 0 degree and less than 90 degrees. The combined structure breaks through the connection mode of the prior crossed shaft type universal joint shaft coupling and solves the vibration problem of the transmission shaft; meanwhile, the combined structure does not change the included angle between transmission shafts and the operating rotating speed of the transmission shafts, thereby reducing the operating vibration amplitude of the transmission shafts substantially; vibration reduction in the structure is more than three fourths of that of the prior proposal; moreover, the proposal is simple and easy to carry out and is suitable for the connection of a plurality of shafts.

Owner:DONGFENG MOTOR CORP HUBEI

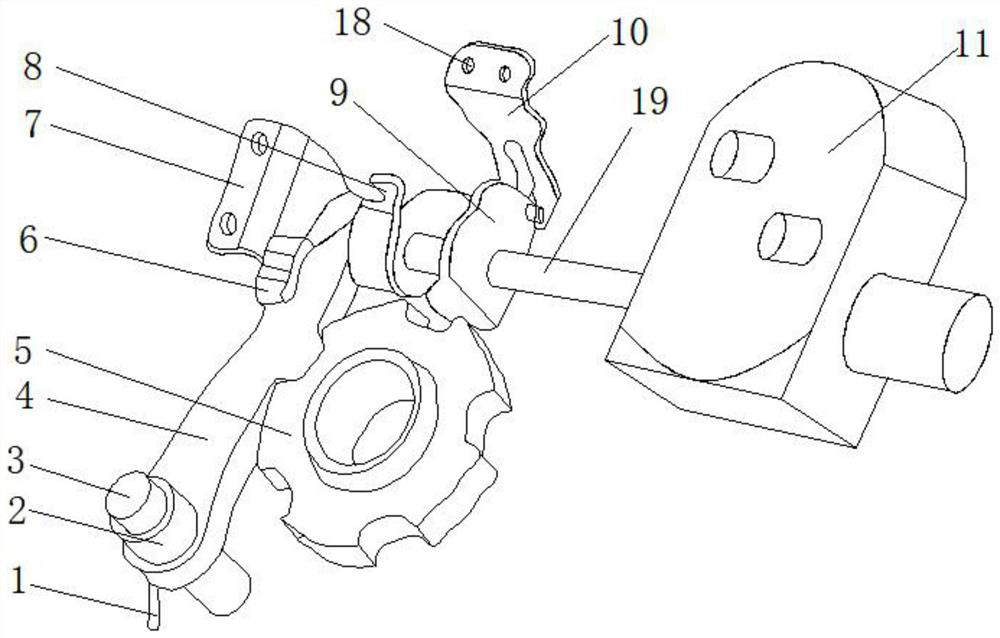

Two-gear reducer with P-gear structure for pure electric vehicle

PendingCN111677831AOptimize layoutAvoid high rpmGearingGearing controlReduction driveElectric machinery

The invention discloses a two-gear reducer with a P-gear structure for a pure electric vehicle. The two-gear reducer comprises an electronic shifter and a two-gear reducer body. One side of the electronic shifter is provided with a P-gear locking shaft, one end of the P-gear locking shaft is provided with a P-gear fixing guide plate, one side of the P-gear fixing guide plate is provided with a P-gear guide block torsion spring, one end of the P-gear guide block torsion spring is provided with a P-gear locking guide block, the lower side of the P-gear locking guide block is provided with a P-gear locking plate, and one side of the P-gear locking plate is in clamping connection with a P-gear locking wheel. According to the two-gear reducer, by using speed ratio regulation, the high efficiency range of a motor is expanded, and the working rotation speed of the motor is reduced; a two-gear electric bridge can compensate for the power drop caused by the rotation speed increase by shifting aworking point of a high-rotation-speed region to a low- rotation-speed region, during second-gear high-speed running, downshifting acceleration is used for overtaking, and driving safety under a highspeed condition is guaranteed; and with a P-gear parking function, it is guaranteed that a vehicle is safely parked in a stationary state.

Owner:HANTENG AUTOMOBILE CO LTD

Aggregate conveyer of concrete station

InactiveCN100553920CRealize shock-free brakingRealize maintenance-free useMixing operation control apparatusEngineeringConstruction aggregate

The invention discloses an aggregate conveying device for a concrete mixing station, comprising: a lifting track (110), a lifting bucket (130), a winch (140), a parking switch (150) and a mixer (120), and the lifting track (110) is inclined Place; the hoist (140) is positioned at the top of the hoisting track (110), connected with the hoisting bucket (130), and drives the hoisting bucket (130) to slide along the hoisting track (110), and the conveying device also includes a waiting bucket positioned above the agitator (120). The hopper (270), and the angle α between the lifting track (110) and the horizontal direction is less than or equal to 60 degrees. The present invention adds an intermediate waiting hopper to separate the working cycle of the hoist from the stirring cycle. The hoist can work continuously without waiting for the mixing time of the mixer. At the same time, the installation angle of the hoisting track is reduced, the load of the hoist is reduced, and the reliability of the hoist is improved. improve.

Owner:SANY HEAVY IND CO LTD (CN)

Pipeline compressor model stage with flow coefficient being 0.0293 and impeller design method

InactiveCN106382256AHigh head coefficientWheel hub ratioGeometric CADPump componentsImpellerEngineering

The invention provides a pipeline compressor model stage with the flow coefficient being 0.0293. The pipeline compressor model stage comprises an impeller, a vaneless diffuser, a curve and a backflow device; the impeller is located at the position of an inlet of the model stage, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is located at the position of an outlet of the model stage, and the vaneless diffuser is communicated with the backflow device through the curve; and the machine mach number Mu2 of the model stage ranges from 0.35 to 0.65, the flow coefficient phi1 of a design point is equal to 0.0293, the energy head coefficient tau of the design point is equal to 0.614, the polytropic efficiency etapcl under the discharge coefficient working condition designed under all mach numbers ranges from 0.838 to 0.843, and the applied flow scope is 60% to 150% that of the design point. The invention further provides a design method of the impeller of the model stage. The model stage is high in efficiency, high in energy head coefficient, large in hub ratio and small in span; by means of the model stage, a light medium compressor can have the high running efficiency and the wide working condition scope; and meanwhile, the working rotating speed of a rotor can be reduced, the bearing span can be decreased, and the stability of the rotor is improved.

Owner:SHENYANG TURBO MASCH CORP +1

Louvered vertical axis resistance wind turbine

ActiveCN103233859ALow maximum speedReduce working speedWind motor controlFinal product manufactureFan bladeTurbine

The invention discloses a louvered vertical axis resistance wind turbine, and belongs to the field of wind power generation. The principle includes that four louvered fan blades are symmetrically mounted on a vertical axis, each fan blade comprises a plurality of movable plates and fixed plates which are mounted into a vertical row at intervals, one fan blade is constantly placed at a windward position when the fixed wind turbine encounters wind with a certain strength, the movable plates at the top of the fan blade are blown and driven to realize self-starting, first-moving blades mounted on the outer side surfaces of the fan blades shift the movable plates through helical gear boxes at proper positions in the rotating process to generate rotating torque, the movable plates drop to a position parallel to the fixed plates when the first-moving blades do not generate the rotating torque, so that rotating resistance is minimum, the rotating torque of a resistance fan is in direct proportion to a windward area, the rotating resistance is in direct proportion to a choke area, the windward area to the choke area can reach hundreds to one by the aid of a movable plate structure, and the efficiency of the resistance wind turbine is greatly improved. By the aid of the structure, the manufacturing cost of the resistance wind turbine is low, and power can be improved by increasing the areas, so that wind power generation is high-power and low-cost.

Owner:魏宏君

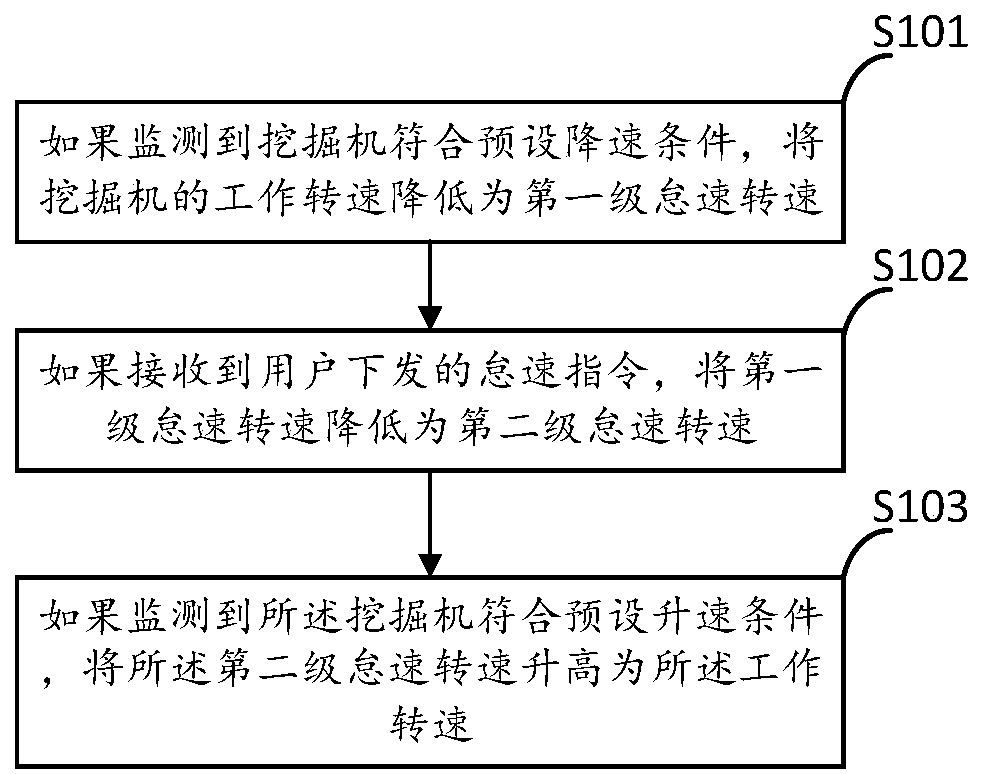

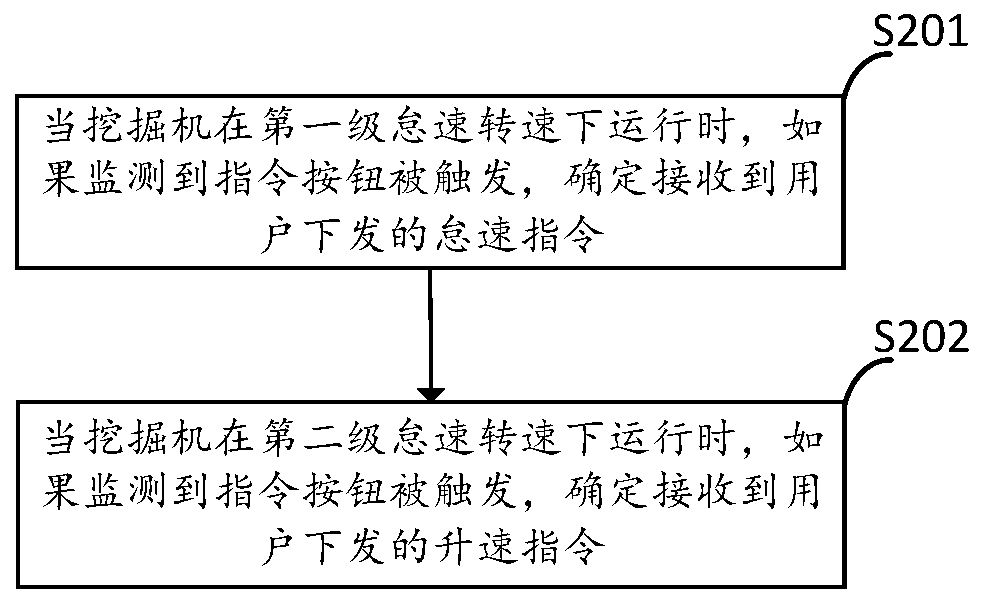

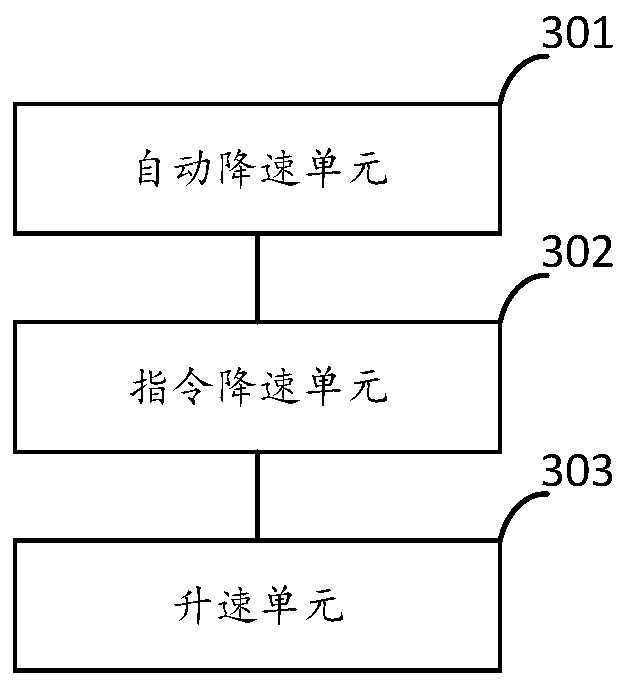

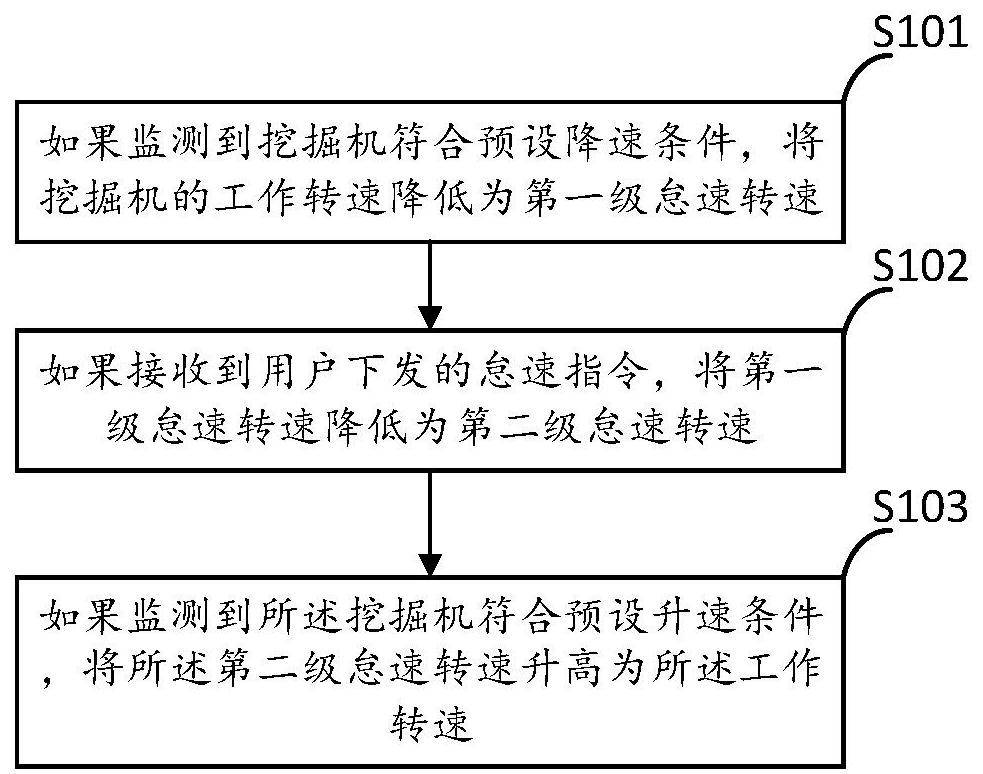

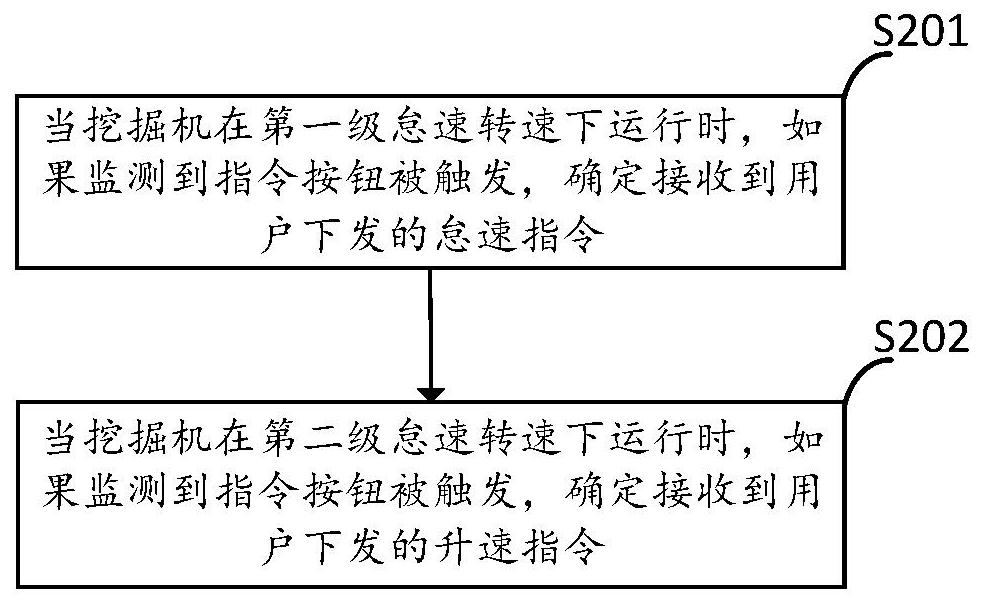

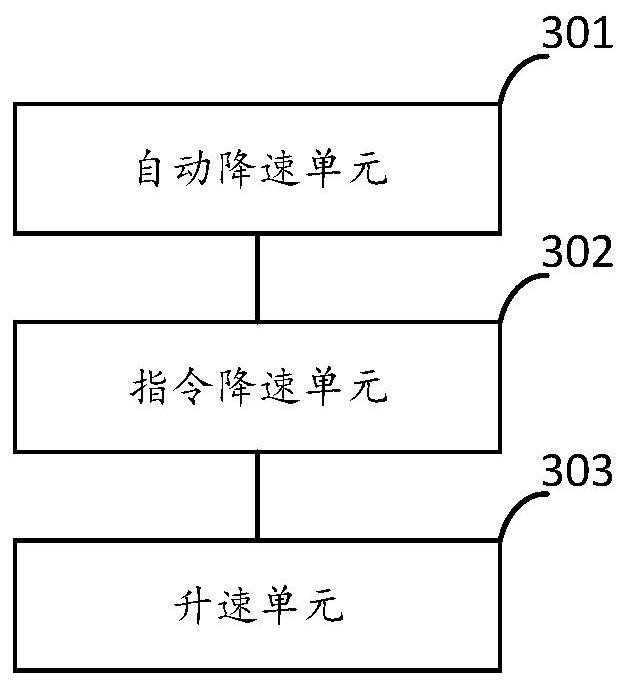

Idle-speed control method and device for excavator as well as control equipment

ActiveCN111456146AReduce working speedReduce fuel consumptionSoil-shifting machines/dredgersIdle speed controlControl engineering

The invention provides an idle-speed control method and device for an excavator as well as control equipment, which relate to the technical field of idle-speed control, and are applied to a controllerof the excavator. The method comprises the following steps: reducing working rotation speed of the excavator to be first-stage idle-speed rotation speed if the excavator is monitored to meet to preset speed reduction conditions which include not receiving an excavator start-up instruction within first preset time length, receiving a start-up instruction of an automatic idle-speed mode and monitoring that the excavator does not change a gear within the first preset time length; if the idle-speed instruction issued by a user is received, reducing the first-stage idle-speed rotation speed to besecond-stage idle-speed rotation speed; and increasing the second-stage idle-speed rotation speed to be working rotation speed if the excavator is monitored to meet preset speed increase conditions which include receiving a speed increase instruction, monitoring that the excavator changes the gear, receiving a cancel instruction of the automatic idle-speed mode of the excavator and receiving the excavator start-up instruction. The idle-speed control method can effectively reduce an excavator action blocking phenomenon, and reduces oil consumption.

Owner:SHANGHAI SANY HEAVY IND

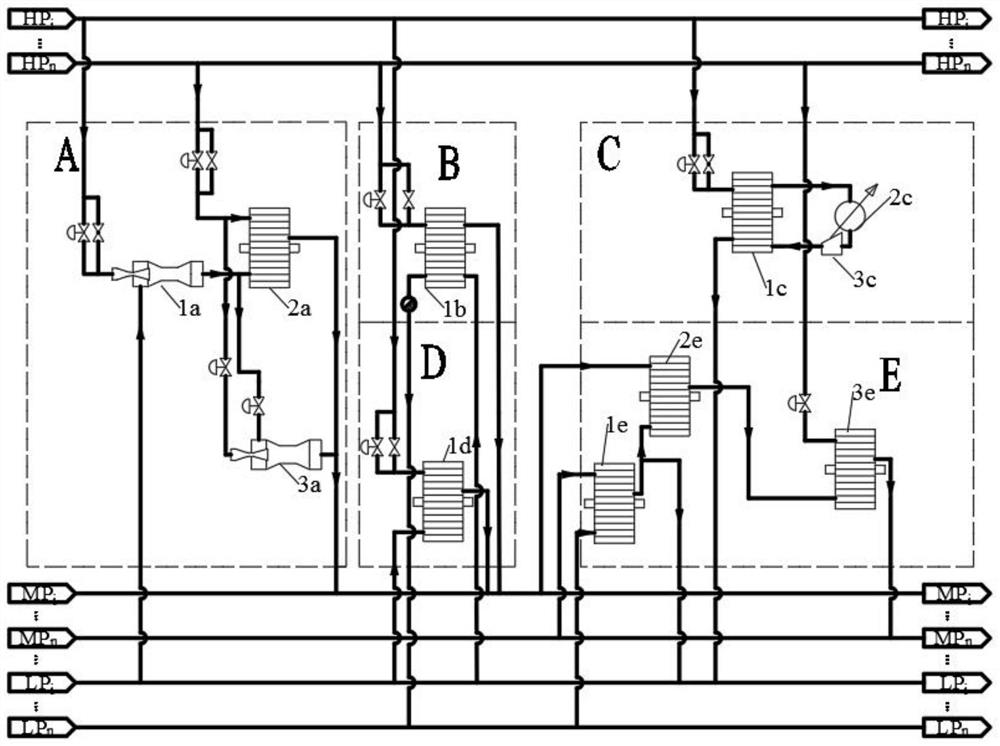

Power switching network implementation method based on wave rotor equipment

ActiveCN114562341AIncrease pressureAvoid wastingCombination enginesJet pumpsThermodynamicsPower switching

The invention discloses a power switching network implementation method based on wave rotor equipment, and relates to the technical field of engineering energy conservation. Pressure energy is directly transmitted through unsteady gas waves, expansion cooling of public engineering steam and the work exchange process of high-pressure steam and low-pressure steam are achieved, a flexible and diversified public steam work exchange network is formed with the assistance of a high-expansion-ratio injection supercharger, and the energy-saving purpose is achieved; the wave rotor and the jet pressurizer are arranged in different forms according to working characteristics, so that the functions of an expansion cooling process of high-pressure steam, a pressurizing and warming process of low-quality steam, a work exchange process of high-pressure steam and low-pressure steam and the like are realized, and external shaft work does not need to be consumed; the practical problems of current industrial pressure reduction, temperature reduction pressure energy loss and low extra steam production amount are solved, the sustainable development principle is met, and energy consumption reduction of an industrial process device is facilitated.

Owner:艾肯(江苏)工业技术有限公司 +1

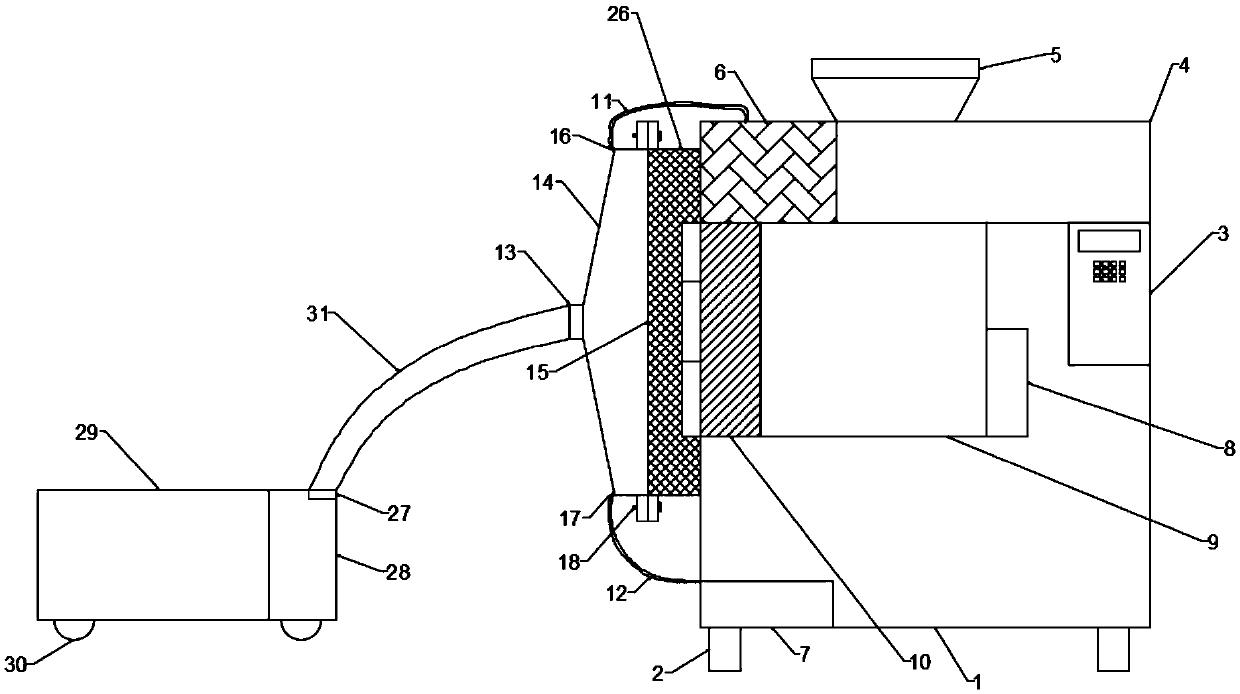

Bread whipping mechanism with automatic material gathering function

InactiveCN109527405AWith automatic material collection functionSpeed up sendingCream substitutesEngineeringWhipped cream

The invention discloses a bread whipping mechanism with an automatic material gathering function. The bread whipping mechanism comprises a body, a work cavity, a control mechanism, a power mechanism,a material delivering mechanism, a ventilation mechanism, and a gathering mechanism. The work cavity is mounted on the upper part of the left side of the body. The material delivering mechanism is mounted on the top of the body. The control mechanism is arranged on the middle of the right side of the body. The power mechanism is arranged on the middle of the left side of the body. The ventilationmechanism is mounted on the lower part of the left side of the body. The gathering mechanism is movably connected to the left end of the work cavity. Four corners of the lower end of the body are provided with support legs. Through the cooperation of all mechanisms, the whipping mechanism can quickly whip cream and gather the cream, compared with a conventional cream whipping machine, the structure is novel, the whipping efficiency is high, and cream with different hardness can be produced according to the needs.

Owner:泗县给力食品机械有限公司

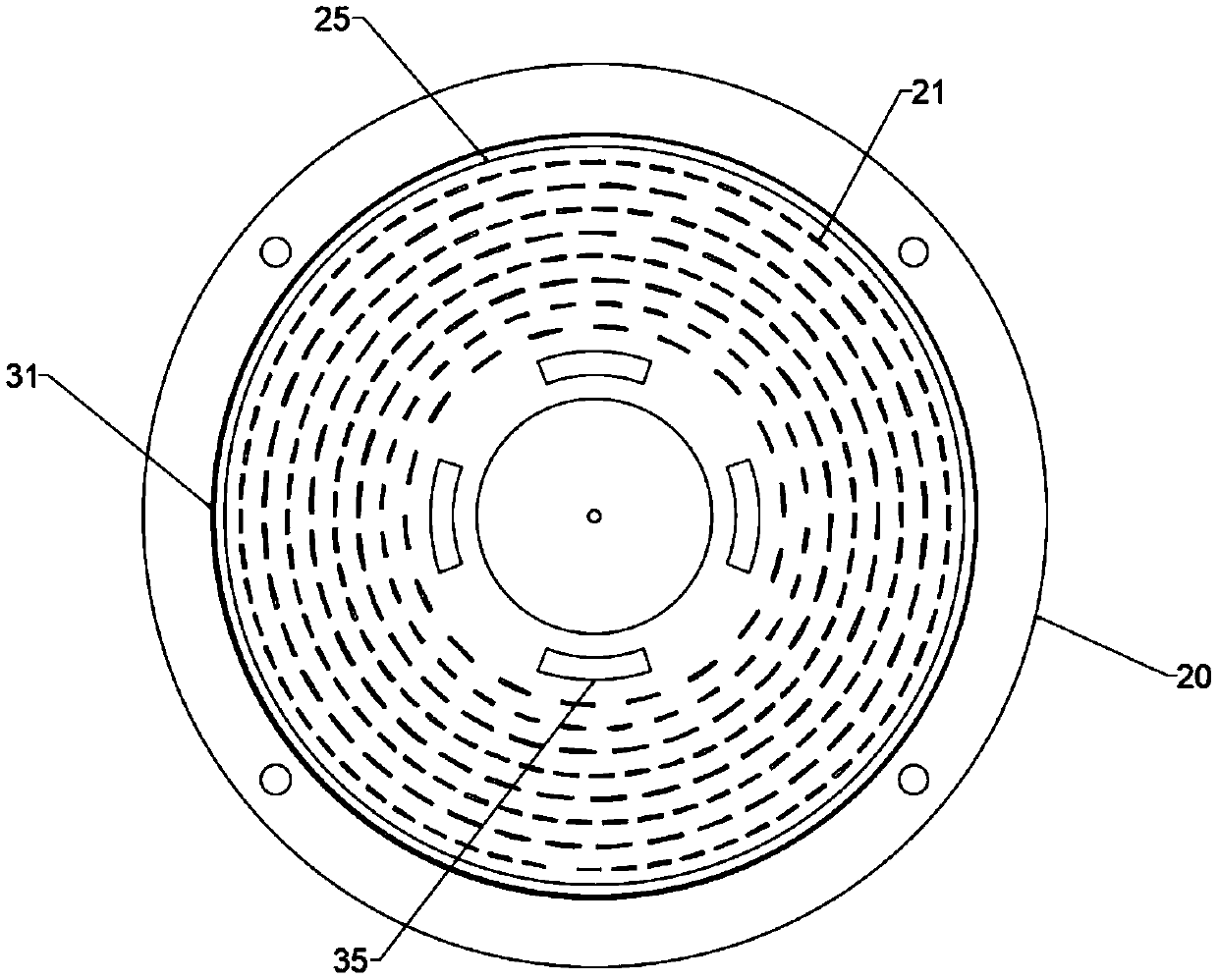

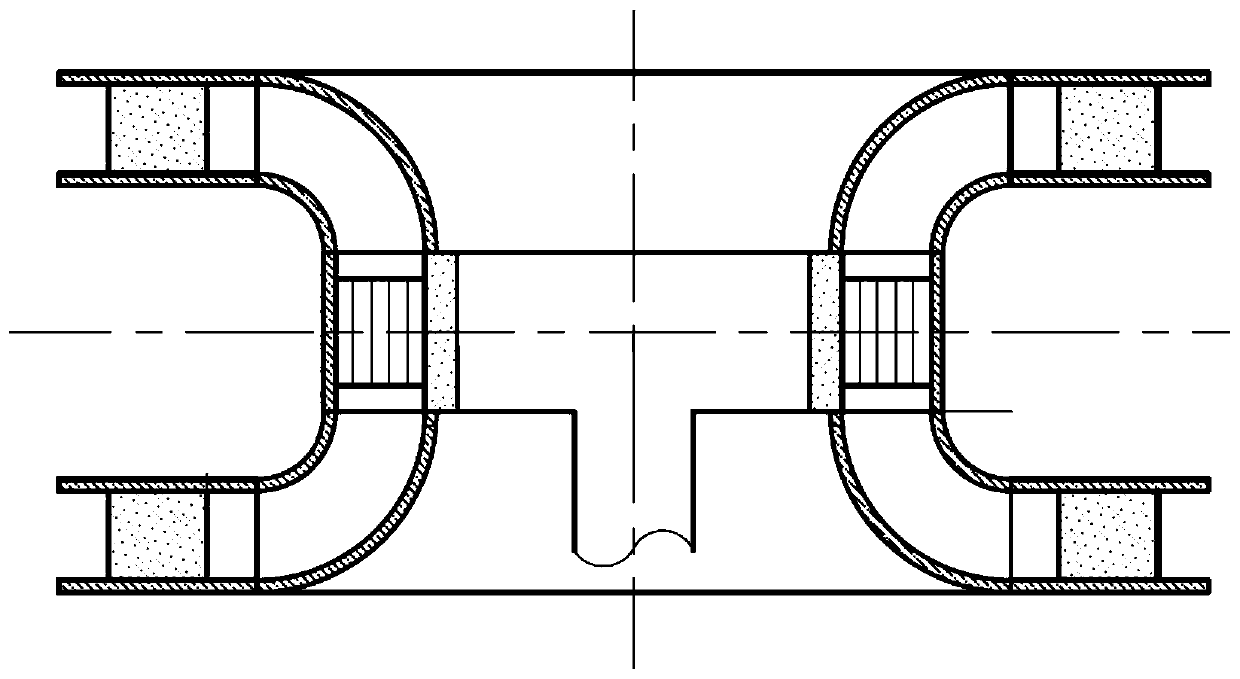

U-shaped flow channel impulse turbine suitable for oscillating water column type wave power generation

InactiveCN110953020AImprove energy conversion efficiencyGood self-starting characteristicsBlade accessoriesStatorsImpellerWave power generation

The invention discloses a U-shaped flow channel impulse turbine suitable for oscillating water column type wave power generation. The air turbine comprises a hub, moving blades, moving impellers, arc-shaped guide sections and guide blade sections; the two ends of the hub are provided with the corresponding moving impellers; the moving impellers rotate about the hub; the moving impellers are correspondingly provided with the moving blades; moreover, the two arc-shaped guide sections connected with each other are arranged at the two sides of the moving impellers; the guide blade sections are arranged circumferentially at the end parts, away from the moving impellers, of the arc-shaped guide sections correspondingly; and each guide blade section is provided with a circle of guide blades evenly arranged in the circumferential direction. The air turbine has high energy conversion efficiency, a good self-starting property, relatively low working speed, a relatively wide flow coefficient range and relatively small working noise.

Owner:TSINGHUA UNIV

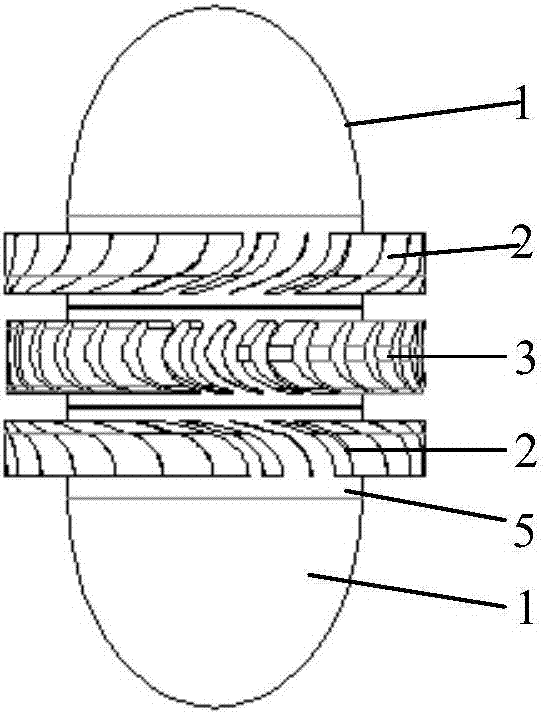

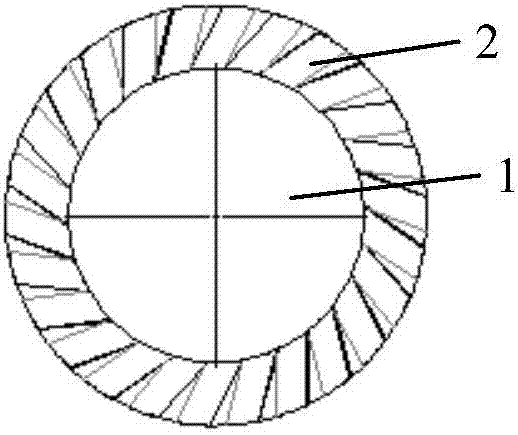

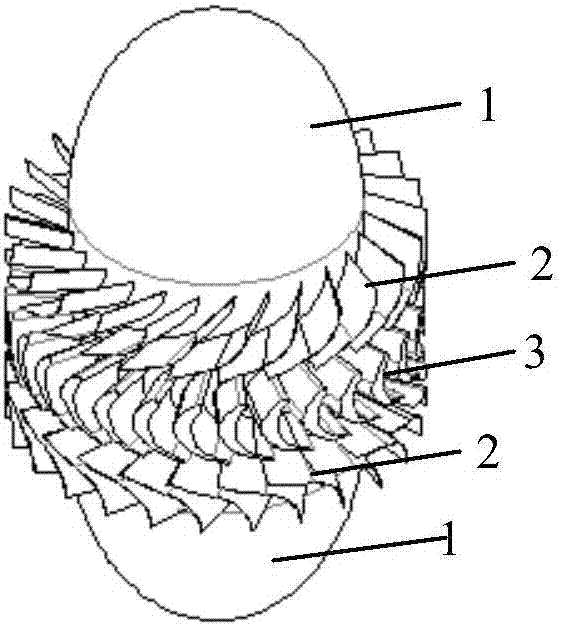

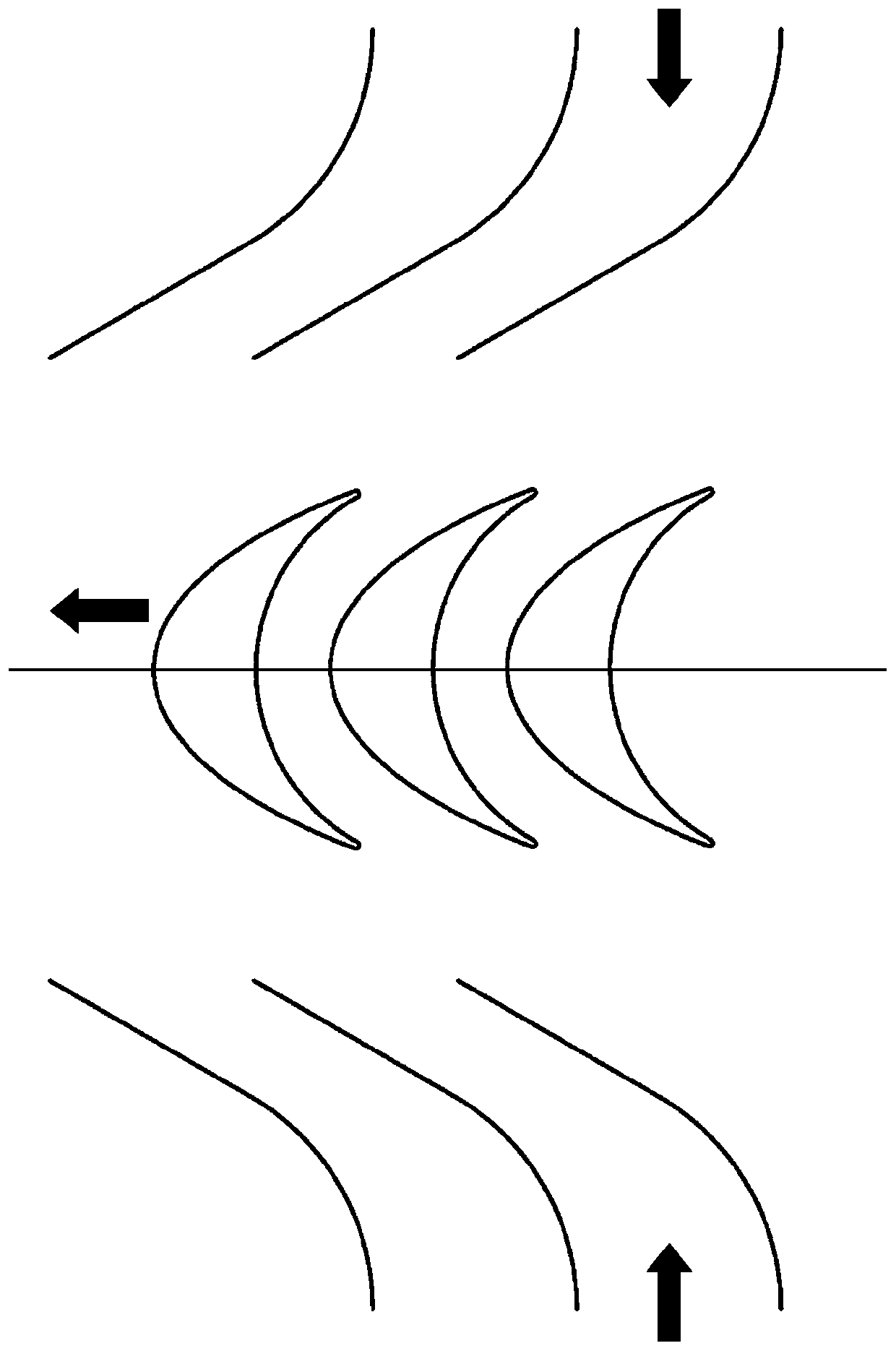

A Self-pitching Controlled Blade Turbine Optimized Based on Traditional Wells Turbine

ActiveCN108361145BImprove Cycle Average EfficiencyImprove turbine efficiencyHydro energy generationMachines/enginesWells turbineEngineering

The invention discloses a self-pitching control blade turbine optimized based on a traditional Wells turbine. The self-pitching control blade turbine comprises a tubular hub; hub heads are mounted onthe two sides of the hub correspondingly; a movable blade wheel which can rotate around the hub is arranged on the hub in a nested mode; two or more movable blades are evenly arranged on the outer wall of the movable blade wheel in the circumferential direction; the movable blades are hinged to the movable blade wheel through pivots; a shaft sleeve with a key groove is arranged on a wheel disc ofthe movable blade wheel; a turbine shaft is mounted on the shaft sleeve, wherein one side of the turbine shaft extends out of the hub heads, and the turbine shaft can synchronously rotate with the movable blade wheel; and the upper side and the lower side of the movable blade wheel are further each provided with a circle of flow guiding blade set in the circumferential direction of the hub. According to the self-pitching control blade turbine, the movable blades can freely swing between an upper limiting point and a lower limiting point around the pivots of the movable blades, so that the deflection angle is autonomously changed according to the size and direction of a coming flow, in this way, the mounting angles of the movable blades can be changed at any time at different stages of a period of waves, and the period average efficiency of the turbine in the actual sea state is improved accordingly.

Owner:OCEAN UNIV OF CHINA

Pipeline compressor model level of 0.022 in flow coefficient and impeller designing method

InactiveCN106704257AHigh head coefficientImprove operational efficiencyGeometric CADPump componentsImpellerEngineering

The invention provides a pipeline compressor model level of 0.022 in flow coefficient. The pipeline compressor model level comprises an impeller, a vaneless diffuser, a bend and a backflow device. The impeller is positioned at an inlet of a ninth model level, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is positioned at an outlet of the ninth model level, and the vaneless diffuser is communicated with the backflow device through the bend; machine mach number Mu2 of the ninth model level is 0.35-0.6, design point flow coefficient phi 1 is 0.022, design point energy head coefficient t is 0.588, polytropic efficiency npcl in design flow coefficient working condition under each mach number is 0.812-0.817, and applied flow range is 60-150% of a design point. The invention further provides a design method of the impeller with the model level. The ninth model level is high in efficiency and energy head coefficient, large in rub ratio and small in span; by adopting the model level, a light-medium compressor is enabled to have high running efficiency and wide working condition range, working rotation speed of a rotor can be lowered, bearing span can be reduced, and stability of the rotor can be improved.

Owner:SHENYANG TURBO MASCH CORP +1

Excavator idle speed control method, device and control equipment

ActiveCN111456146BReduce working speedReduce fuel consumptionSoil-shifting machines/dredgersIdle speed controlControl engineering

The invention provides an idle speed control method, device and control equipment of an excavator, which relate to the technical field of idle speed control and are applied to a controller of an excavator. If the start command of the excavator is not received within the preset first time period, the start command of the automatic idle mode is received and the gear position of the excavator is not changed within the preset first time period), the working speed of the excavator is reduced to the first level idle speed; if the idle speed command issued by the user is received, the first level idle speed is reduced to the second level idle speed; if it is detected that the excavator meets the preset The excavator changes the gear, receives the cancel instruction of the automatic idle mode of the excavator and receives the start instruction of the excavator), and increases the second-stage idle speed to the working speed. The invention can effectively reduce the stuck phenomenon of the excavator and reduce fuel consumption.

Owner:SHANGHAI SANY HEAVY IND

Louvered Vertical Axis Resistance Wind Turbine

ActiveCN103233859BLow maximum speedReduce working speedWind motor controlFinal product manufactureVertical axis wind turbineFan blade

The invention discloses a louvered vertical axis resistance wind turbine, and belongs to the field of wind power generation. The principle includes that four louvered fan blades are symmetrically mounted on a vertical axis, each fan blade comprises a plurality of movable plates and fixed plates which are mounted into a vertical row at intervals, one fan blade is constantly placed at a windward position when the fixed wind turbine encounters wind with a certain strength, the movable plates at the top of the fan blade are blown and driven to realize self-starting, first-moving blades mounted on the outer side surfaces of the fan blades shift the movable plates through helical gear boxes at proper positions in the rotating process to generate rotating torque, the movable plates drop to a position parallel to the fixed plates when the first-moving blades do not generate the rotating torque, so that rotating resistance is minimum, the rotating torque of a resistance fan is in direct proportion to a windward area, the rotating resistance is in direct proportion to a choke area, the windward area to the choke area can reach hundreds to one by the aid of a movable plate structure, and the efficiency of the resistance wind turbine is greatly improved. By the aid of the structure, the manufacturing cost of the resistance wind turbine is low, and power can be improved by increasing the areas, so that wind power generation is high-power and low-cost.

Owner:魏宏君

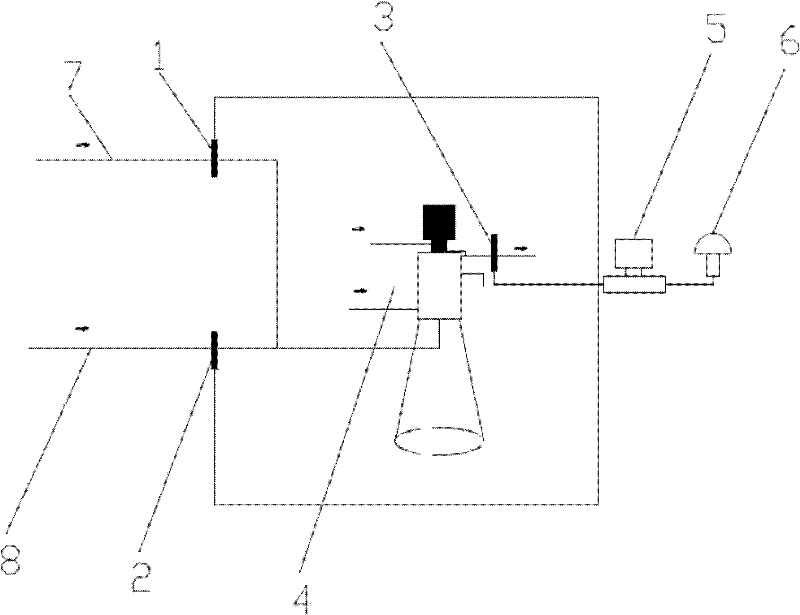

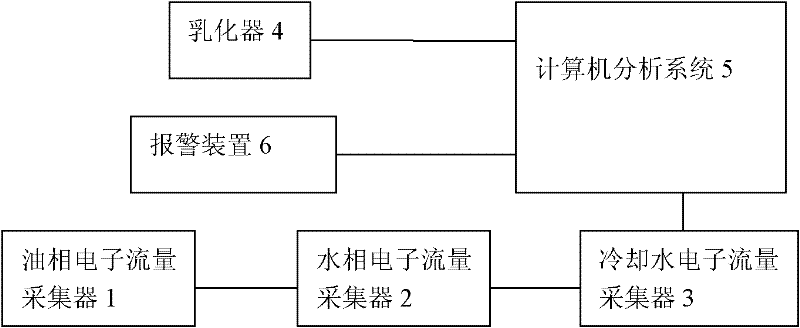

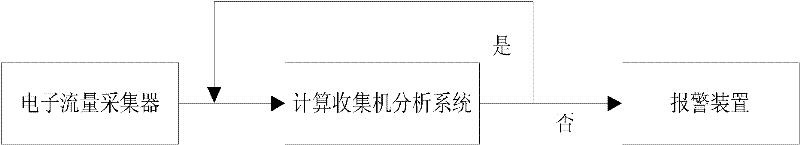

Protection device for water and material supply failures of emulsion explosive emulsifier and its control method

InactiveCN102351617ASolve quality problemsFix security issuesExplosive working-up apparatusExplosive AgentsEmulsion explosive

The invention discloses a protection device for water and material supply failures of an emulsion explosive emulsifier and its control method. The device comprises: an emulsifier, a computer collection and analysis system, and an alarm device. The device also includes electronic flow data collectors that are respectively connected to a water phase, an oil phase and the emulsifier. The emulsifier is in connection with the computer analysis system connected to the alarm device. The electronic flow collectors are installed at the water inlet or outlet of the emulsifier, and on an oil phase pipeline as well as a water phase pipeline. According to the invention, the water and material supply failures and other problems of the emulsifier are monitored in real time through the electronic flow data collectors, so that the device of the invention realizes automation, enhances response accuracy, and improves the intrinsic safety of emulsion explosive production, and also makes the production process more efficient, more beneficial, stabler and smoother.

Owner:广东宏大民爆集团有限公司

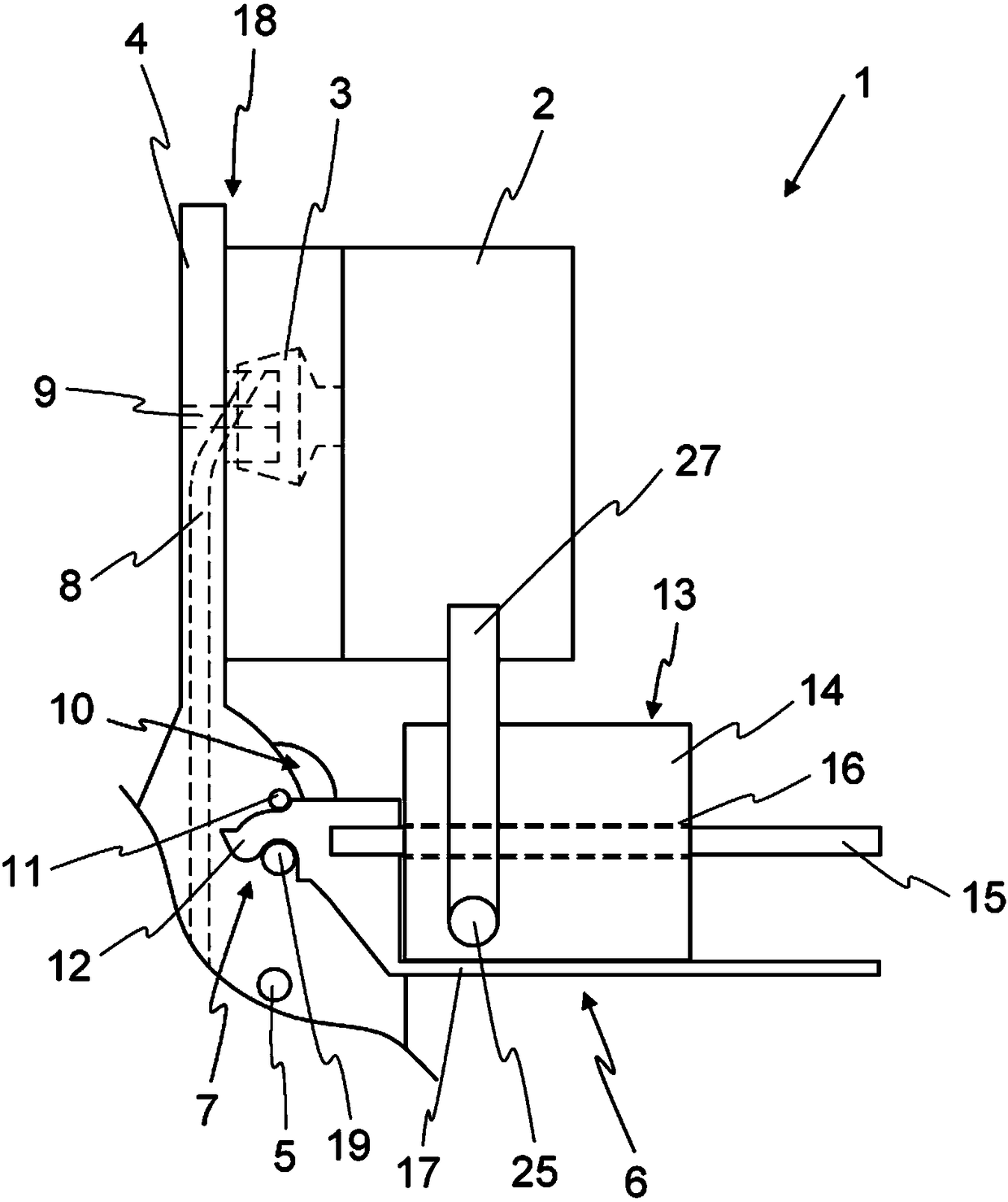

Open-end rotor spinning device and method for operating an open-end spinning device

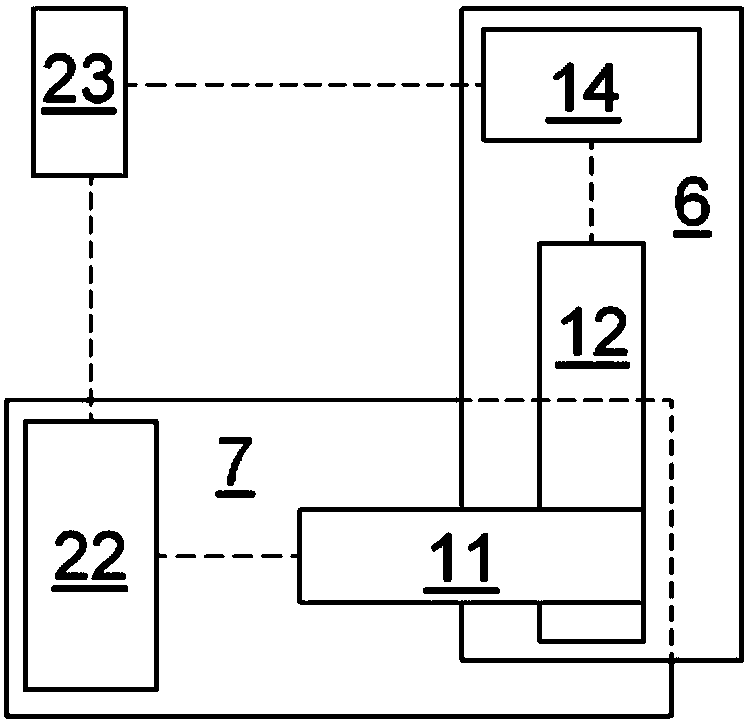

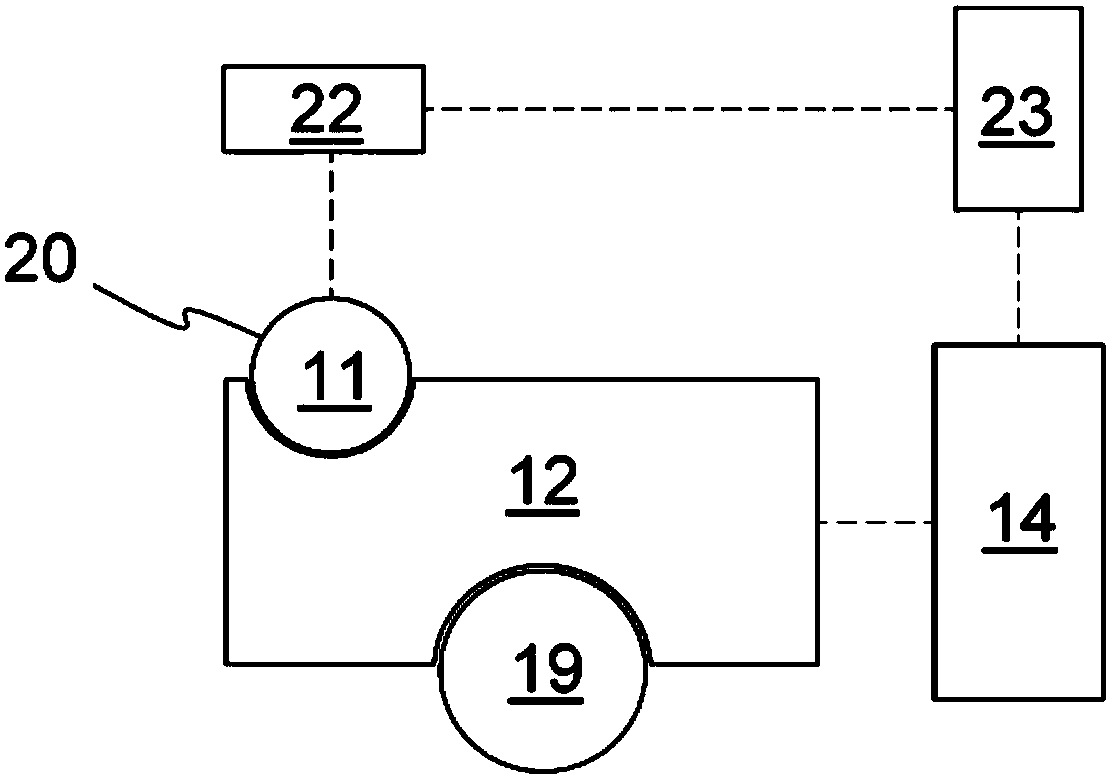

InactiveCN108342796AFully automatedRepair work goes wellContinuous wound-up machinesOpen-end spinning machinesYarnFiber

An open-end rotor spinning device (1) has: a spinning rotor (3) arranged in a rotor housing (2), the rotor housing (2) being covered by a top cover member (4); a swinging device (6) used for opening and closing the top cover member (4) and a locking device (7) for locking the top cover member. A fiber supply passage (8) and a yarn output passage (9) are arranged in the top cover member (4). The swinging device (6) and the locking device (7) are connected to each other. In an operating method of the open-end rotor spinning device (1) having the spinning rotor (3) rotating in the rotor housing (2) during a spinning operation, the rotor housing (2) is closed or opened by the top cover member (4). In order to open or close the rotor housing (2), the top cover member (4) swings by means of theswinging device (6), and, in order to lock the top cover member (4), the top cover member is locked by means of the locking device (7). The swinging device (6) and the locking device (7) are optionally connected to each other or disconnected from each other.

Owner:MASCHINENFABRIK RIETER AG

Model stage and impeller design method of pipeline compressor with flow coefficient 0.02

ActiveCN106382253BHigh head coefficientWheel hub ratioGeometric CADPump componentsImpellerLine tubing

The invention provides a model stage of a pipeline compressor with a flow coefficient of 0.02, including an impeller, a vaneless diffuser, a bend, and a reflux device. The outlet position of the model stage, the vaneless diffuser and the recirculator are connected through a bend; the machine Mach number M of the model stage u2 =0.35~0.65, design point flow coefficient Φ 1 =0.02, the design point energy head coefficient τ=0.53, the variable efficiency η under the design discharge coefficient working condition at each Mach number pcl =0.82~0.85, the applied flow range is 60%‑150% of the design point. A design methodology for the model stage impeller is also provided. The model stage of the present invention has high efficiency, high energy head coefficient, large hub ratio, and small span. Adopting the model stage can make the light medium compressor have higher operating efficiency and a wider range of working conditions, and at the same time can reduce the rotor work. speed, reduce the bearing span, and improve the stability of the rotor.

Owner:SHENYANG TURBO MASCH CORP +1

Tail cooling rotor engine

PendingCN114320960ALow and high temperature performance requirementsLower working temperatureContinuous combustion chamberInternal combustion piston enginesAir compressionEngineering

An air compression cavity of an air compressor A of the tail cooling rotor engine is communicated with an air collection cavity of an end cover from left to right through a peripheral cold flow channel A of a cold flow tail gas combination body, a peripheral cold flow channel B of an injection backflushing seat and a peripheral cold flow channel C of a main cylinder body; an air compression cavity of the air compressor A is communicated with an air collection cavity of the end cover from left to right through a middle cold flow channel A of the cold flow combination body, a middle cold flow channel B of the rotor, a middle cold flow channel C of the jet backflushing seat and a middle cold flow channel D of the main cylinder. The heat engine is high in efficiency, low in requirement for high-temperature performance of blade materials, low in rotor rotating speed and large in angular momentum, and is suitable for fluid-loaded aircrafts, ships and the like.

Owner:李笑一

Composite structure of transmission shaft end cross coupling

ActiveCN101440844BReduce vibration amplitudeDo not change angleYielding couplingVibration amplitudeUniversal joint

The invention discloses a combined structure of a transmission shaft end crossed shaft coupling. The combined structure comprises a transmission shaft, wherein both ends of the transmission shaft are connected with crossed shaft type universal joint shaft couplings; and the phase angle theta between the crossed shaft type universal joint shaft couplings is more than 0 degree and less than 90 degrees. The combined structure breaks through the connection mode of the prior crossed shaft type universal joint shaft coupling and solves the vibration problem of the transmission shaft; meanwhile, thecombined structure does not change the included angle between transmission shafts and the operating rotating speed of the transmission shafts, thereby reducing the operating vibration amplitude of the transmission shafts substantially; vibration reduction in the structure is more than three fourths of that of the prior proposal; moreover, the proposal is simple and easy to carry out and is suitable for the connection of a plurality of shafts.

Owner:DONGFENG MOTOR CORP HUBEI

Pipeline compressor model stage with flow coefficient being 0.0266 and impeller design method

InactiveCN106382257AHigh head coefficientWheel hub ratioGeometric CADPump componentsImpellerEngineering

The invention provides a pipeline compressor model stage with the flow coefficient being 0.0266. The pipeline compressor model stage comprises an impeller, a vaneless diffuser, a curve and a backflow device; the impeller is located at the position of an inlet of the model stage, the vaneless diffuser is arranged at an outlet of the impeller, the backflow device is located at the position of an outlet of the model stage, and the vaneless diffuser is communicated with the backflow device through the curve; and the machine mach number Mu2 of the model stage ranges from 0.35 to 0.65, the flow coefficient phi1 of a design point is equal to 0.0266, the energy head coefficient tau of the design point is equal to 0.586, the polytropic efficiency etapcl under the discharge coefficient working condition designed under all mach numbers ranges from 0.83 to 0.833, and the applied flow scope is 60% to 150% that of the design point. The invention further provides a design method of the impeller of the model stage. The model stage is high in efficiency, high in energy head coefficient, large in hub ratio and small in span; by means of the model stage, a light medium compressor can have the high running efficiency and the wide working condition scope; and meanwhile, the working rotating speed of a rotor can be reduced, the bearing span can be decreased, and the stability of the rotor is improved.

Owner:SHENYANG TURBO MASCH CORP +1

A calibration method for heavy-duty vehicle electronically controlled silicone oil clutch fan

ActiveCN111608786BReduce working speedReduce the impact of testingVehicle testingCoolant flow controlControl theoryOil temperature

The invention discloses a method for calibrating a heavy-duty automobile electronically controlled silicone oil clutch fan. 1. When the engine is under the limit load and the fan is at the limit speed, whether the engine outlet water temperature exceeds the maximum allowable water outlet temperature of the engine design, if so, it needs to be replaced with a higher power Fan; 2. At a constant engine speed and different engine output power, record the corresponding fan speed when the engine outlet water temperature is maintained within the optimum water temperature range; 3. When the vehicle is actually driving, when the engine is under the output power in step 2 , when the water temperature changes between the optimum water temperature ranges, the fan runs at the corresponding speed measured in step 2. Under the premise of ensuring that the engine is not overheated under extreme load conditions, the engine under common operating conditions of the whole vehicle can be maintained within the optimum working water temperature, air temperature and engine oil temperature range, and at the same time, the working speed of the fan is guaranteed to be the lowest, so as to achieve fuel saving and noise reduction. Purpose.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

Energy-saving control method for spreading machine

ActiveCN100402752CImprove work efficiencyReduce working speedEngine controllersMachines/enginesWork performanceEngineering

The invention discloses an energy-saving control method for paver. Presetting paving thickness, paving width, and paving velocity in paving work are inputted into the collocating cell of engine working point in controller. According to it presetting rotating speed value of engine is obtained. The controller adjusts the engine of paver so that the actual rotating speed of paver is equal to the rotating speed of engine according to the presetting rotating speed value of engine obtained. The method in invention is provided with simple operation, high automaticity. It can adjust the rotating speed of engine according to the change of actual working condition so that not only the whole efficiency is improved but also it is provided with the energy saving under the presence of ensuring working performance.

Owner:SANY HEAVY IND CO LTD (CN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com