Excavator idle speed control method, device and control equipment

An idle speed control and excavator technology, which is applied in the field of devices and control equipment, and excavator idle speed control methods, can solve the problems of the excavator stuck, the engine speed change cannot keep up, and the fuel consumption is high, and the effect of reducing fuel consumption is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

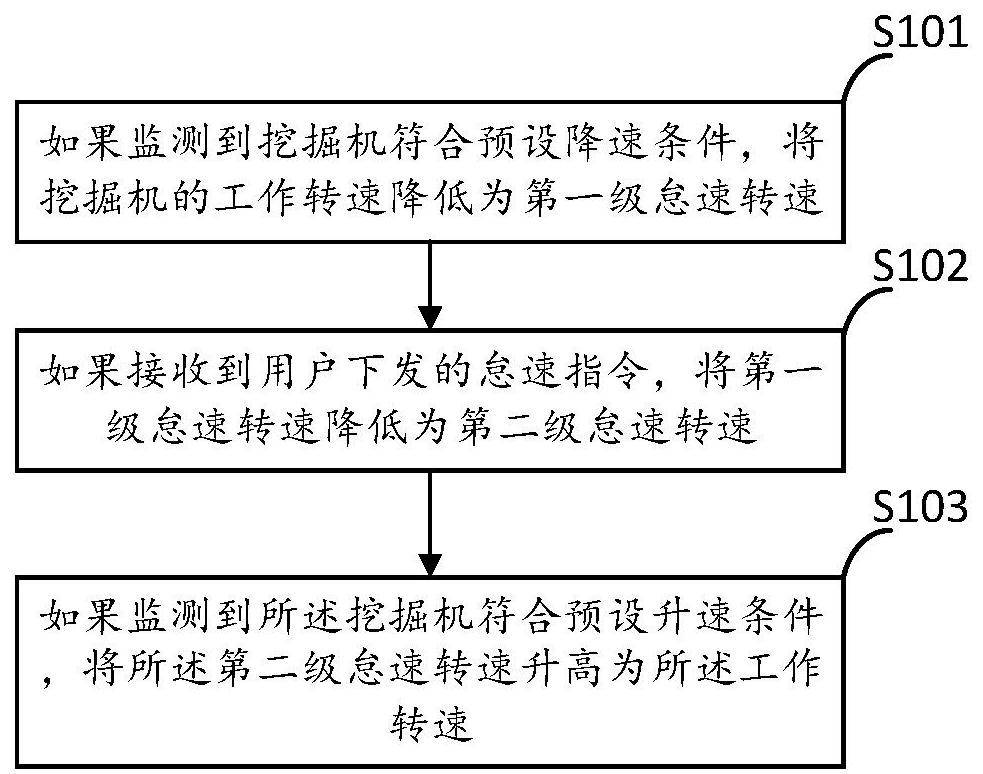

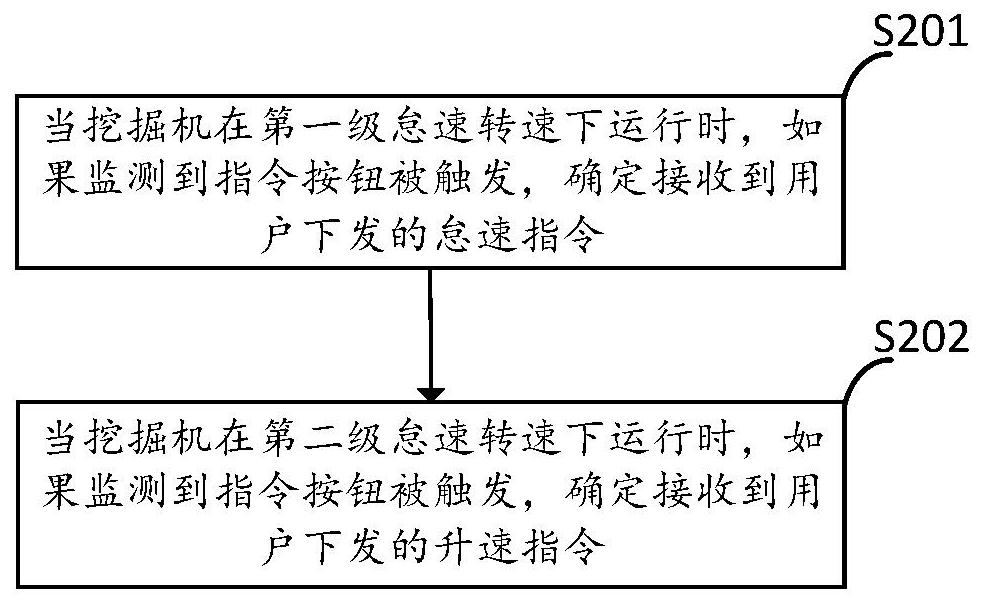

[0040] refer to figure 1 The flow chart of an idle speed control method for an excavator is shown, which is applied to the controller of the excavator and can be executed by electronic devices such as computers and processors. The method mainly includes steps S101 to S103:

[0041] Step S101, if it is detected that the excavator meets the preset speed reduction condition, reduce the working speed of the excavator to the first-stage idle speed. Wherein, the preset deceleration condition includes at least one of the following: the excavator startup command is not received within the preset first time period, the startup command of the automatic idle mode is received, and the excavator is detected not to change within the preset first time period. gear.

[0042] In a specific implementation manner, the operating speed of the excavator is reduced to the first-stage idle speed only when the preset speed reduction conditions are all met at the same time. An exemplary explanation is ...

Embodiment 2

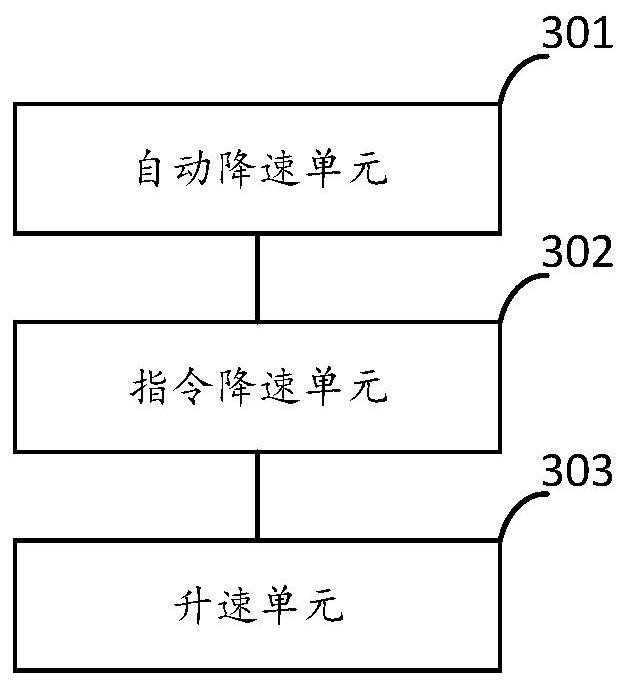

[0058] refer to image 3 The schematic diagram of an excavator idle speed control device shown includes the controller of the excavator, and also includes:

[0059] The automatic deceleration unit 301 is used to reduce the working speed of the excavator to the first-stage idling speed if it is detected that the excavator meets the preset deceleration condition, wherein the preset deceleration condition includes at least one of the following: The start command of the excavator is not received within the first time period, the start command of the automatic idle mode is received, and it is detected that the excavator does not change gears within the preset first time period.

[0060] The command deceleration unit 302 is configured to reduce the idle speed of the first stage to the idle speed of the second stage if an idle speed instruction issued by the user is received.

[0061] The speed-up unit 303 is configured to raise the second-stage idle speed to the working speed if it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com