Composite structure of transmission shaft end cross coupling

A cross coupling and combined structure technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve problems such as large vibration and affecting vehicle comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

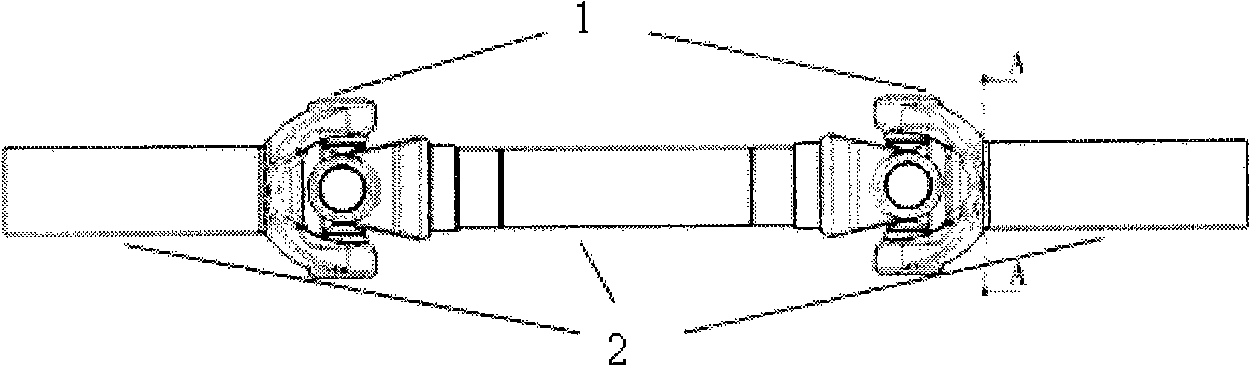

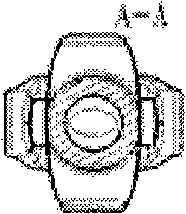

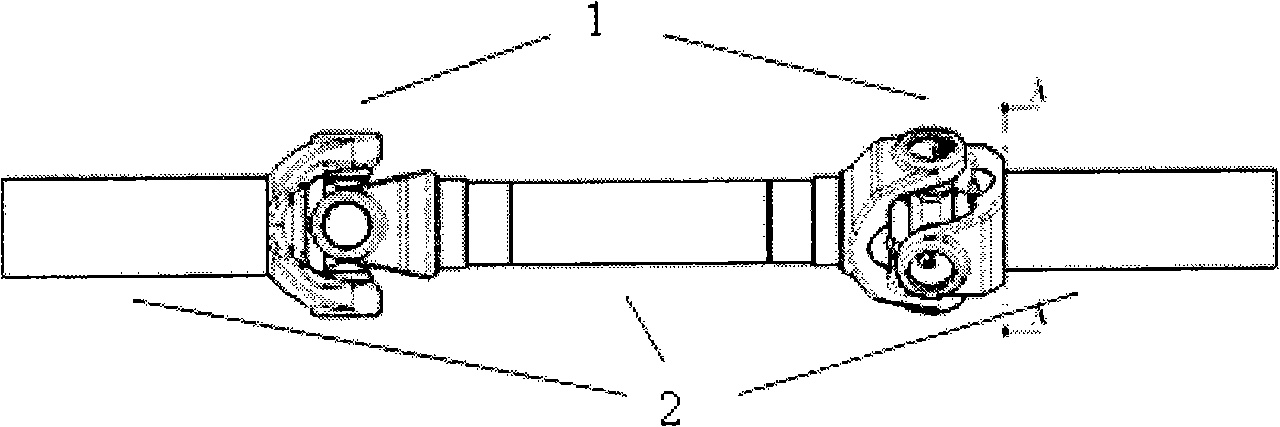

[0013] The inventor made use of the unequal speed characteristic of the output speed of the cross coupling, without changing the structure of the cross shaft universal joint coupling and without changing the angle between the transmission shafts, the cross at one shaft end of the transmission shaft The shaft type universal joint coupling remains different, changing the angle of the other cross shaft type universal joint coupling of the drive shaft, that is, changing the phase angle θ between the cross shaft type universal joint couplings at both ends of the drive shaft (Such as image 3 , 4 As shown), it is found that when the phase angle θ between the cross shaft universal joint couplings at both ends of the transmission shaft is between 0°<θ≤15° and 25°≤θ<90°, the working vibration amplitude of the transmission shaft decreases Maximum, the vibration reduction reaches more than three-quarters of the original scheme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com