Energy-saving control method for spreading machine

A technology for energy-saving control and paver, applied in the direction of engine control, electric program control, electric speed/acceleration control, etc. Efficiency reduction and other issues, to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

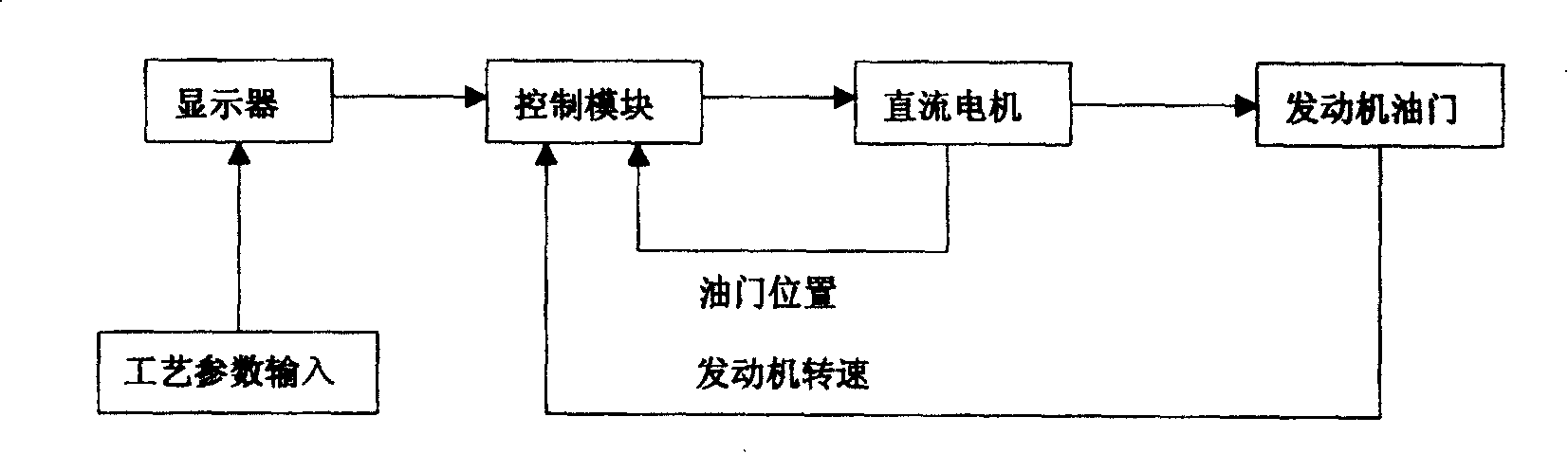

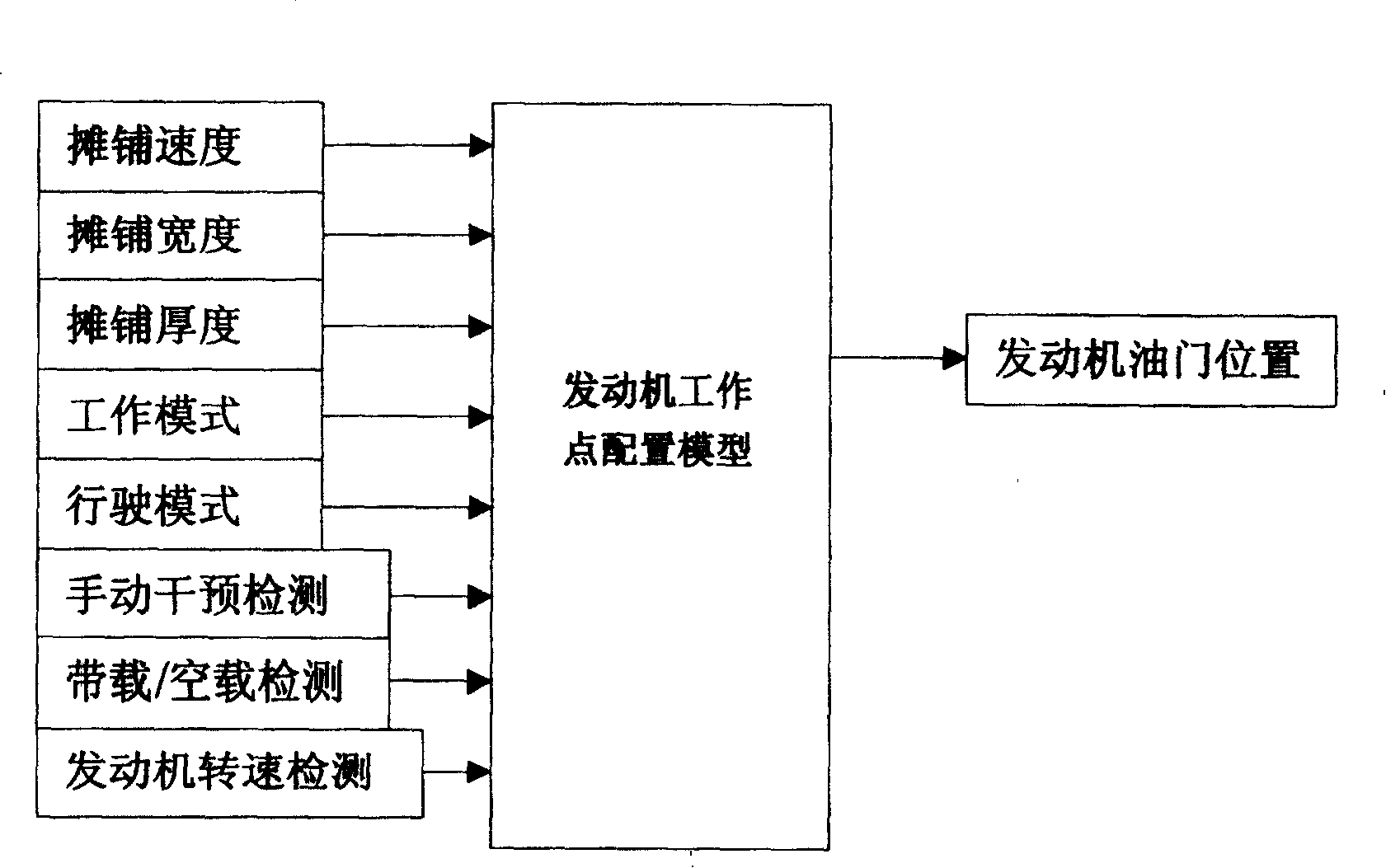

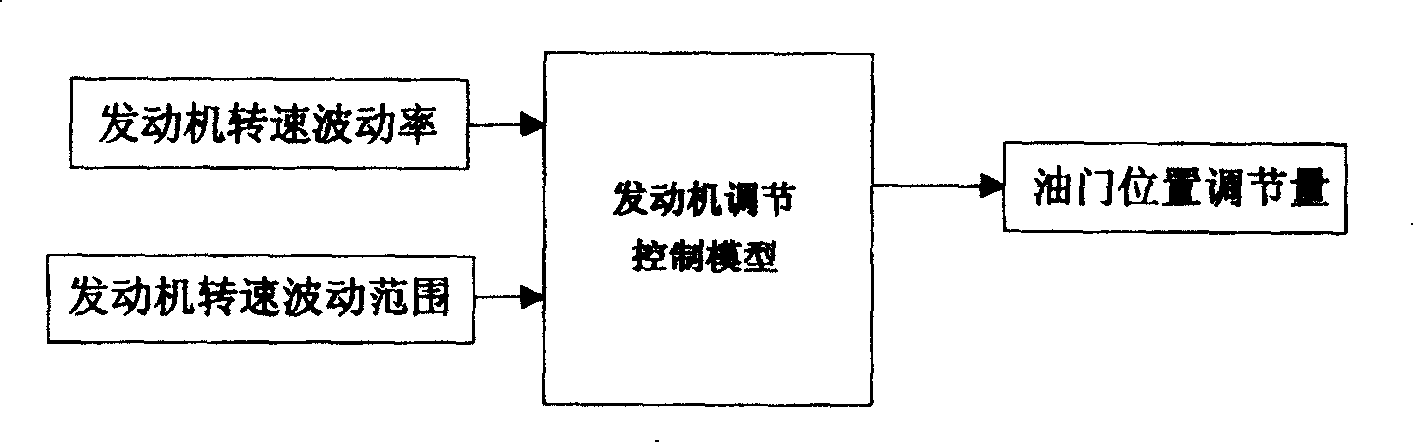

[0032] Such as figure 1 As shown, in the energy-saving control method of the paver of the present invention, the process parameters such as the preset paving thickness, paving width, and paving speed during paving work are input into the control unit through the input unit such as a keyboard and the display unit. In the engine operating point configuration unit of the controller unit, the controller unit obtains the preset engine speed value accordingly, and the controller unit adjusts the paver engine according to the obtained engine preset speed value, so that the actual speed of the paver Equal to the preset speed value. The controller unit drives the adjusting rack of the paver engine through the DC motor to control the speed of the paver engine, or the controller unit directly controls the engine of the electric spray paver. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com