A calibration method for heavy-duty vehicle electronically controlled silicone oil clutch fan

A technology of electronically controlled silicon oil and heavy-duty vehicles. It is applied in the direction of instruments, vehicle testing, machines/engines, etc. It can solve the problems of large access and different minimum fan speed requirements, and achieve the effect of reducing impact and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

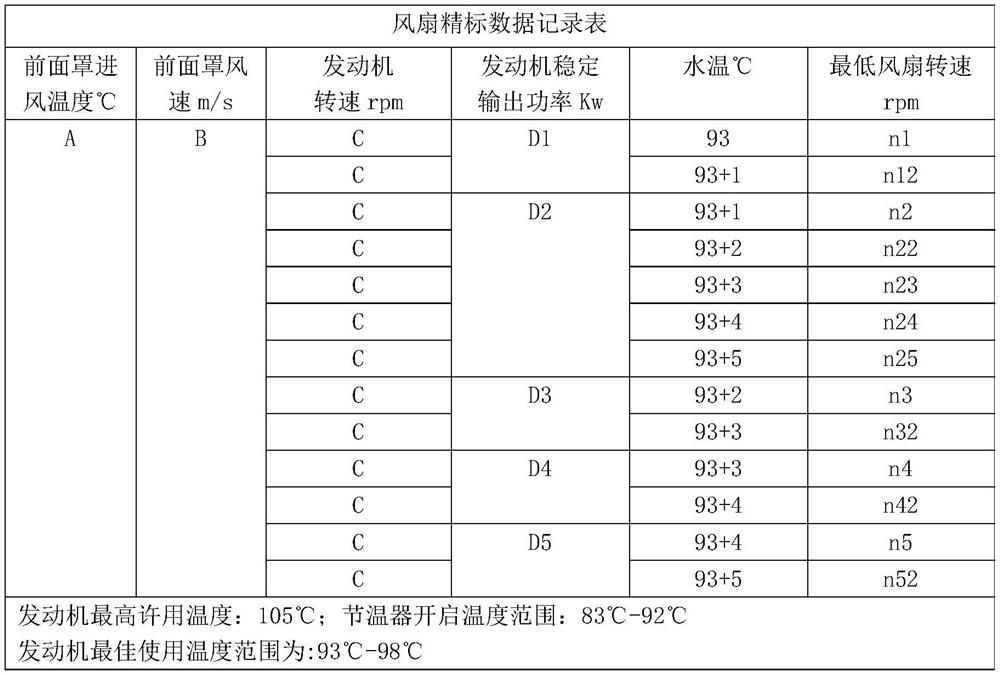

[0023] Fan calibration refers to the process of determining the relationship between the engine outlet water temperature and the fan speed through the heat balance test of the complete vehicle drum for a vehicle equipped with an electronically controlled silicon oil clutch fan.

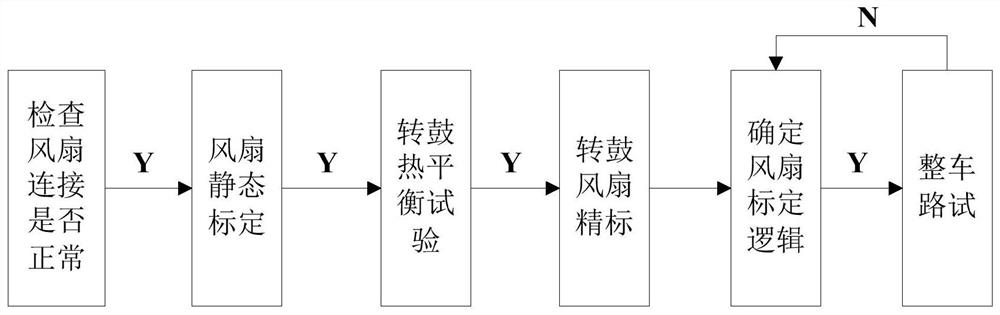

[0024] Such as figure 1 Shown is the calibration process of the electric clutch fan: Before fan calibration, check whether the mechanical connection of the vehicle fan and the electrical circuit connection are normal, check whether all the signals used for testing and calibration are normal, and proceed to the next step of static calibration if normal.

[0025] Static calibration includes calibration of feedforward tables and calibration of PID parameters. After the calibration is completed, the static test is carried out. The static test includes the separation time test of the electronicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com