Reciprocating-piston type oil-less air compressor

An air compressor and reciprocating piston technology, applied in the field of compressors, can solve the problems of increasing the elliptical leakage gap between the piston and the cylinder, the short working life of the sealing ring or the sealing cup, the fatigue damage of the sealing ring or the sealing cup, etc. The effect of averaging motion, reducing slap intensity, reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

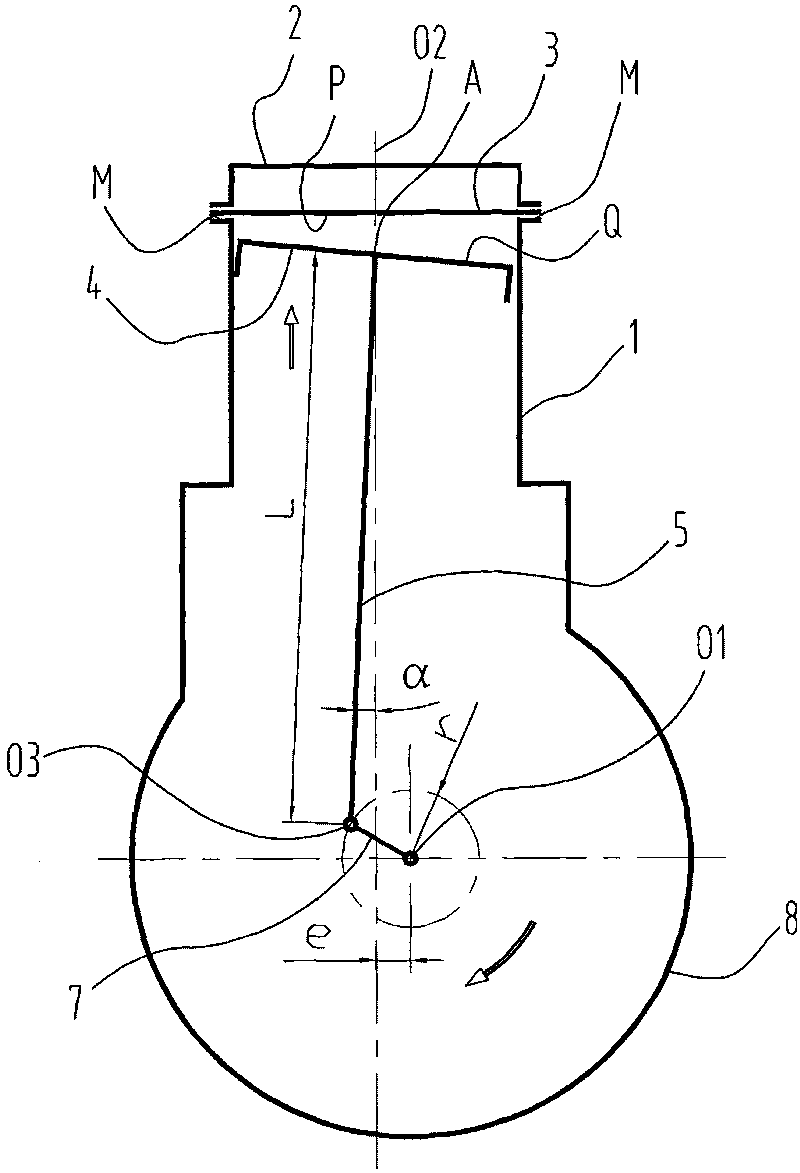

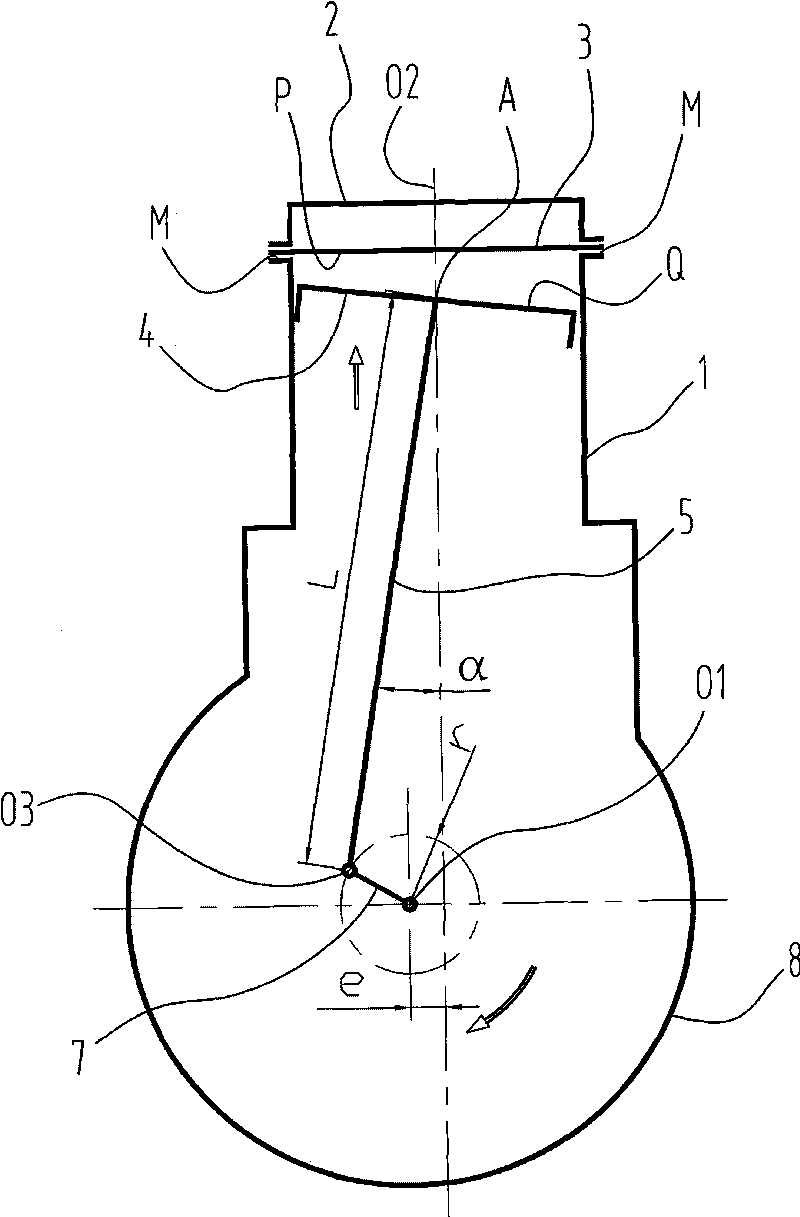

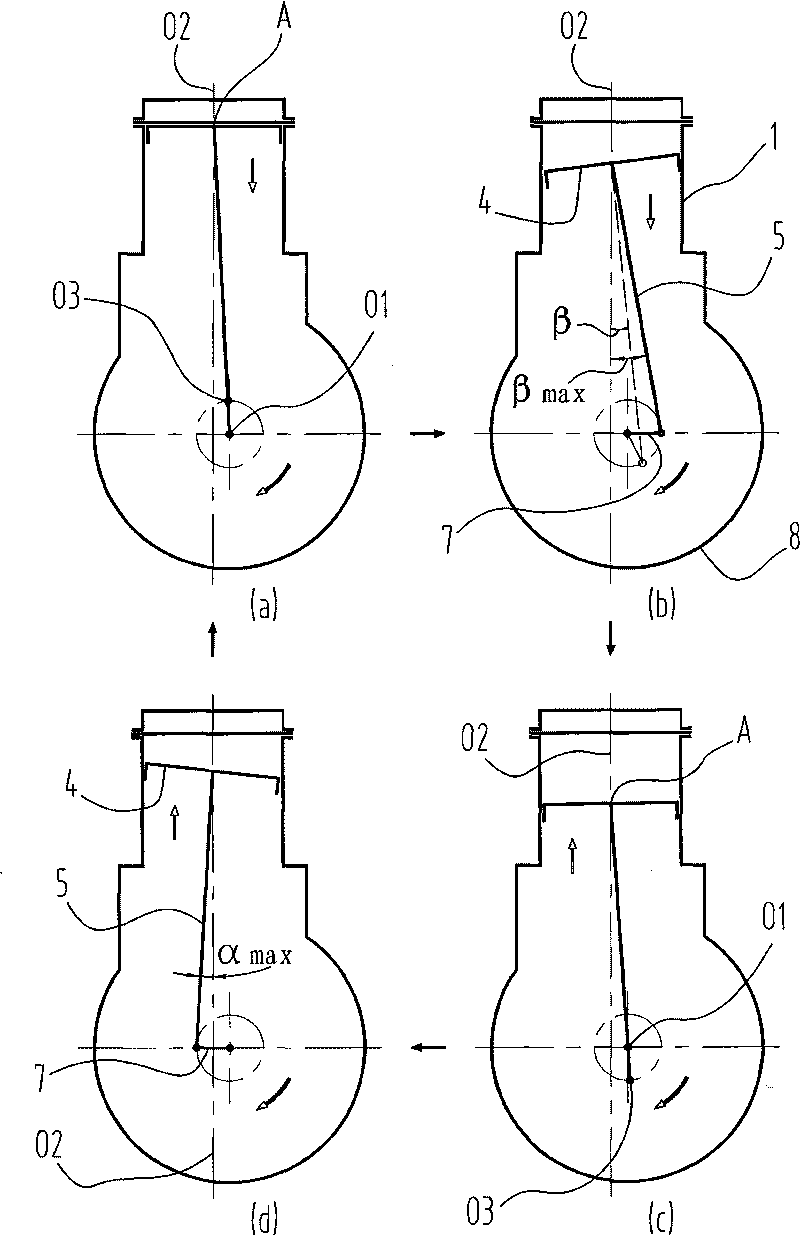

[0056] The present invention will be further described below with specific embodiment: see Figure 1-16 :

[0057] Reciprocating piston type oil-free air compressor, which includes: cylinder 1, cylinder head 2, valve seat 3, piston 4, connecting rod 5, crank pin 6, crankshaft 7 and crankcase 8, wherein said piston 4 and connecting rod 5 Adopt fast connection or the piston 4 and the connecting rod 5 are integrally made, the piston 4 is equipped with a sealing ring or sealing cup 9 made of self-lubricating material, and the big end of the connecting rod 5 is rotatably set on the Crankpin 6 and together with crankpin 6 rotate around the crankshaft rotation axis O1 of crankshaft 7. Piston 4 is placed in cylinder 1 and reciprocates along the direction of cylinder axis O2. Obviously, due to piston 4 and connecting rod 5 are fastened and connected as one, so the piston 4 must have an oscillating motion relative to the cylinder 1; it should be noted that the big end bearing of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com