Recriprocating Compressor

a compressor and lateral pressure technology, applied in the direction of positive displacement liquid engines, piston pumps, lighting and heating apparatus, etc., can solve the problems of difficult suppression of vibrations produced, and achieve the effects of reducing lateral pressure of pistons, reducing energy consumption, and reducing vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

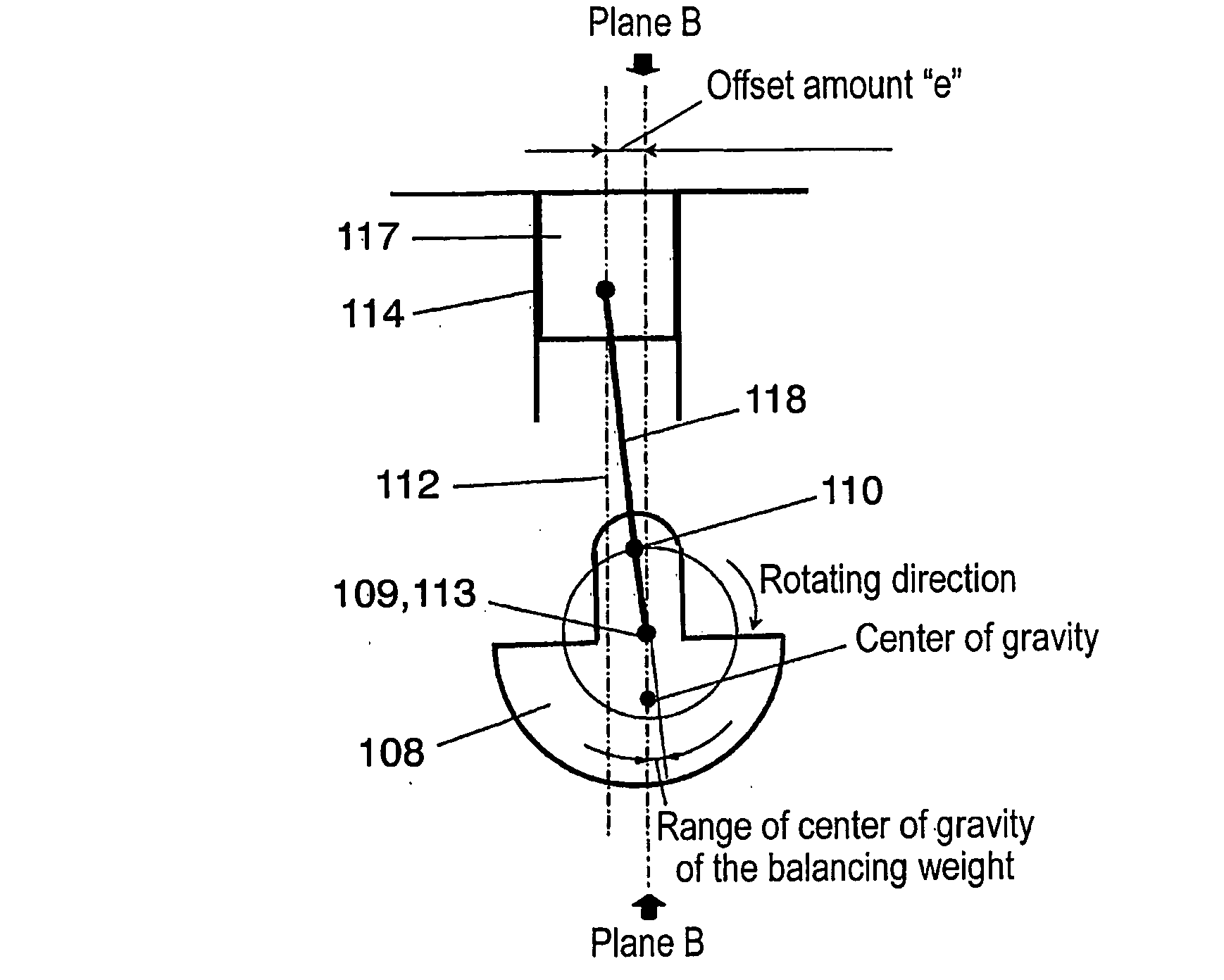

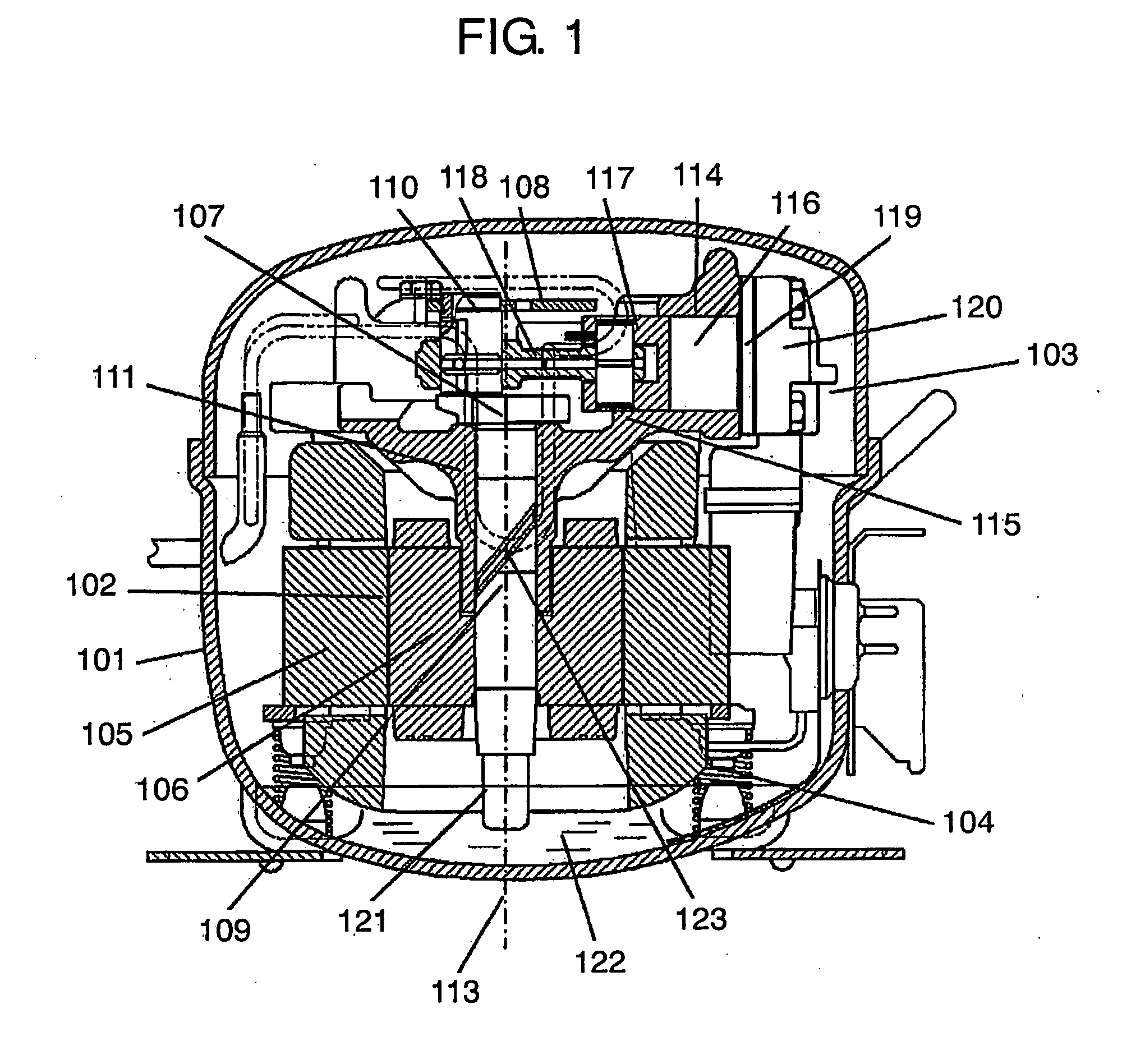

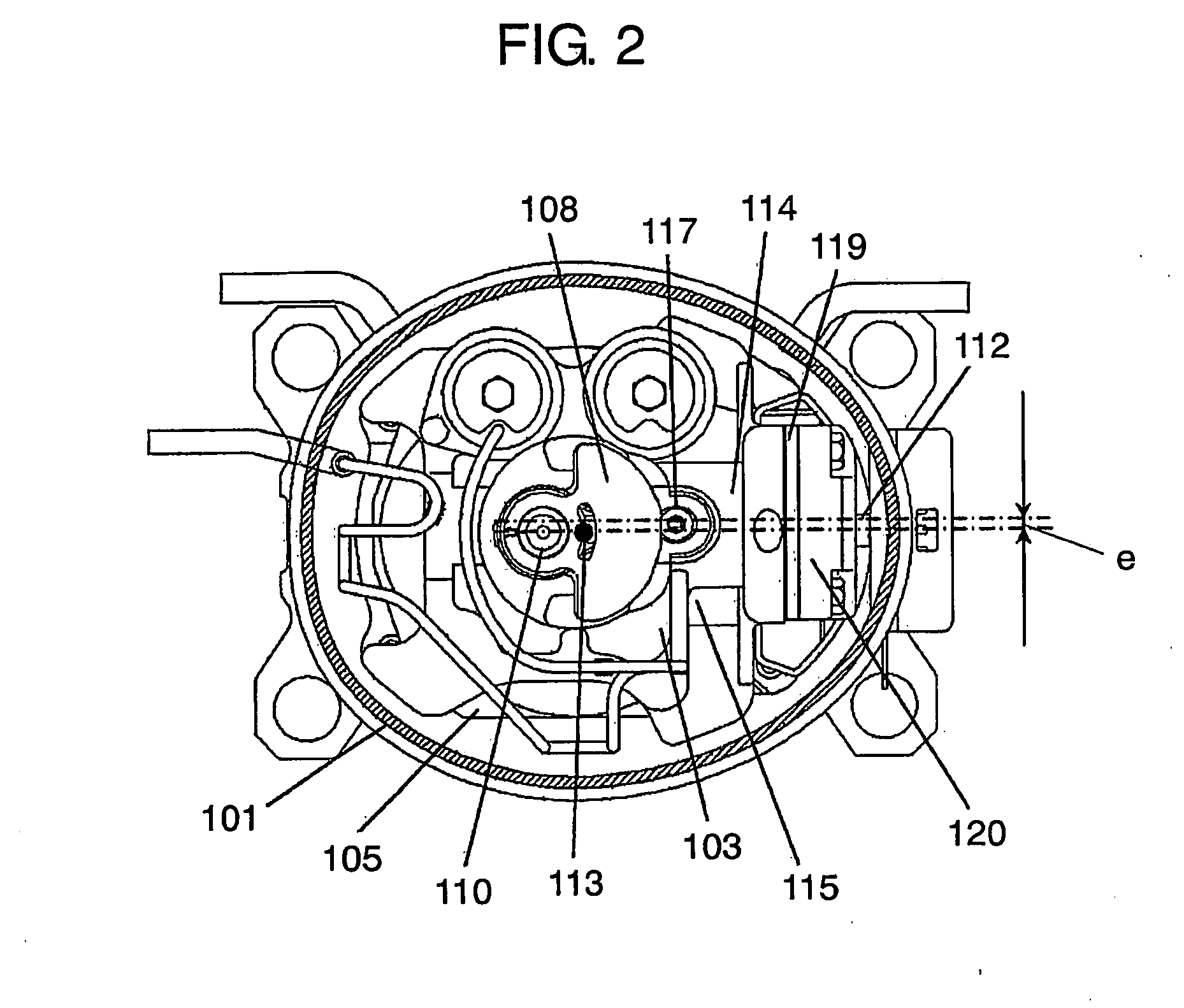

[0017]A reciprocating compressor of the present invention includes a hermetic container which accommodates a compressing element for compressing refrigerant gas. The compressing element comprises the following elements:[0018]a crankshaft generally disposed perpendicularly and having a main shaft and an eccentric section;[0019]a block forming a cylindrical cylinder;[0020]a piston reciprocating in the cylinder;[0021]a connecting rod connecting the eccentric section to the piston; and[0022]a balancing weight for balancing vibrations produced by foregoing elements including at least one of the piston, the connecting rod and the eccentric section.

[0023]The cylinder is placed offset such that the axis lines of both the cylinder and the main shaft will not cross each other, and the balancing weight is placed such that the center of gravity thereof is positioned generally opposite the center of the eccentric section with respect to the axial line of the main shaft and deviated along the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com