Hollow pile with multiple holes on lateral wall

A hollow pile and hole technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of insufficient drainage capacity of hollow piles and low bearing capacity of the pile body, so as to speed up the drainage consolidation rate and improve the strength of the pile body. , the effect of increasing the drainage path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention provides a side wall porous hollow pile which can not only accelerate the drainage consolidation but also improve the bearing capacity of the pile body. If the drainage device is used in the hollow pile core, the effect of getting twice the result with half the effort will be achieved.

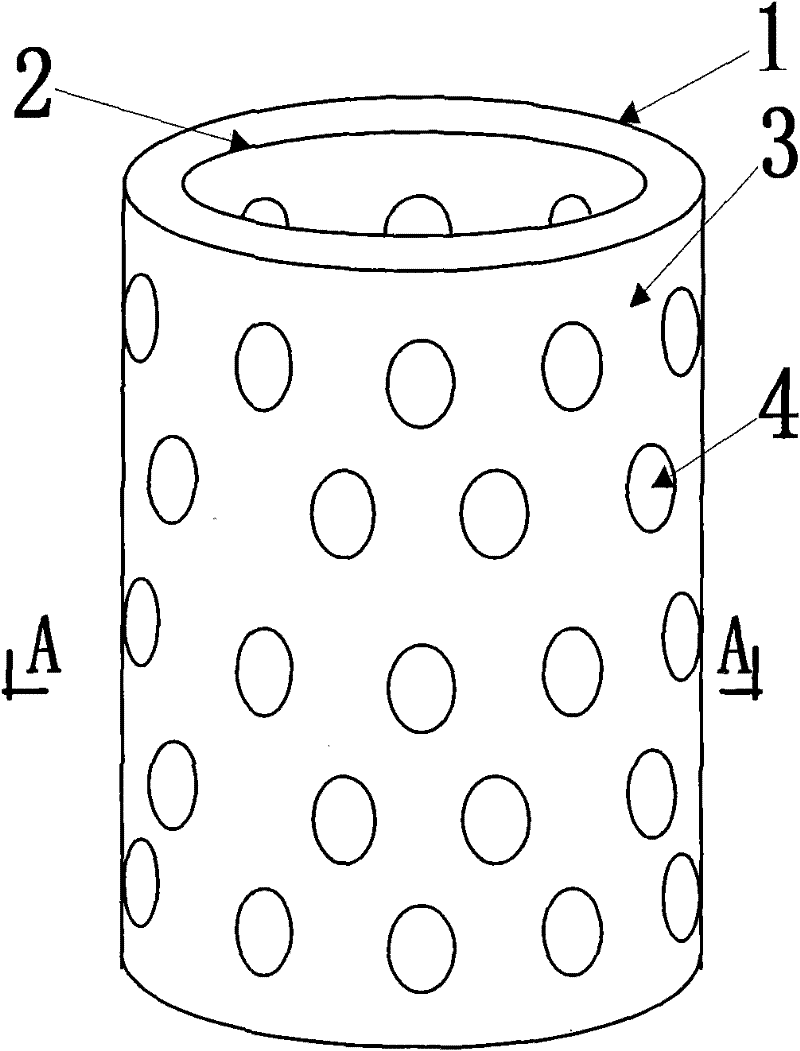

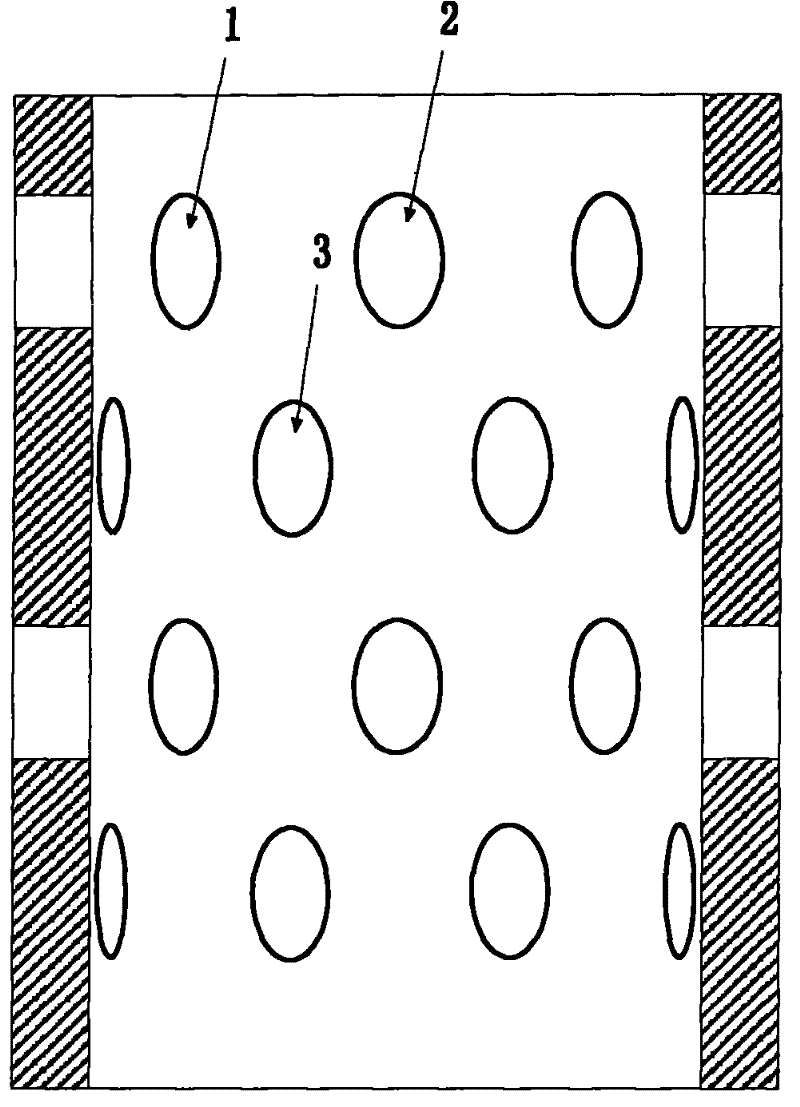

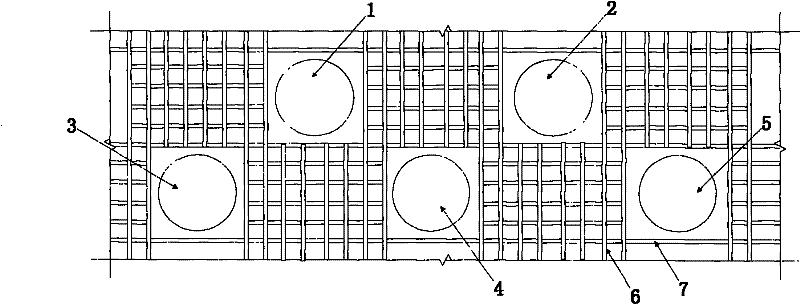

[0020] Such as figure 1 As shown, the porous hollow pile on the side wall includes an outer interface 1 , an inner interface 2 , an outer wall 3 , and holes 4 in the outer wall of the hollow pile. The diameter of the outer interface of the side wall porous hollow pile is 320 mm, and the diameter of the inner interface is 200 mm. The aperture 4 of the side wall hole is 32mm. The holes 4 on the side walls are arranged alternately and form a honeycomb shape. The poured material should try to use concrete with high strength and good workability according to actual needs. This can ensure that the hollow pile with a porous side wall of the present invention achieves proper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com