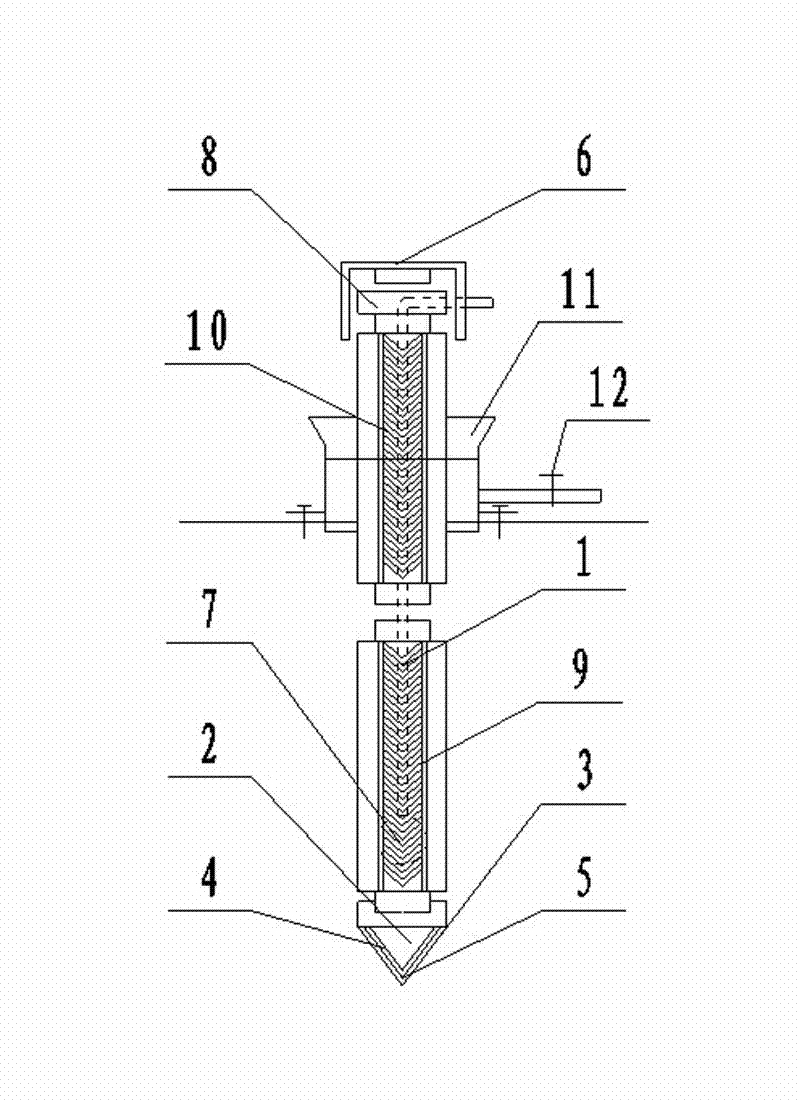

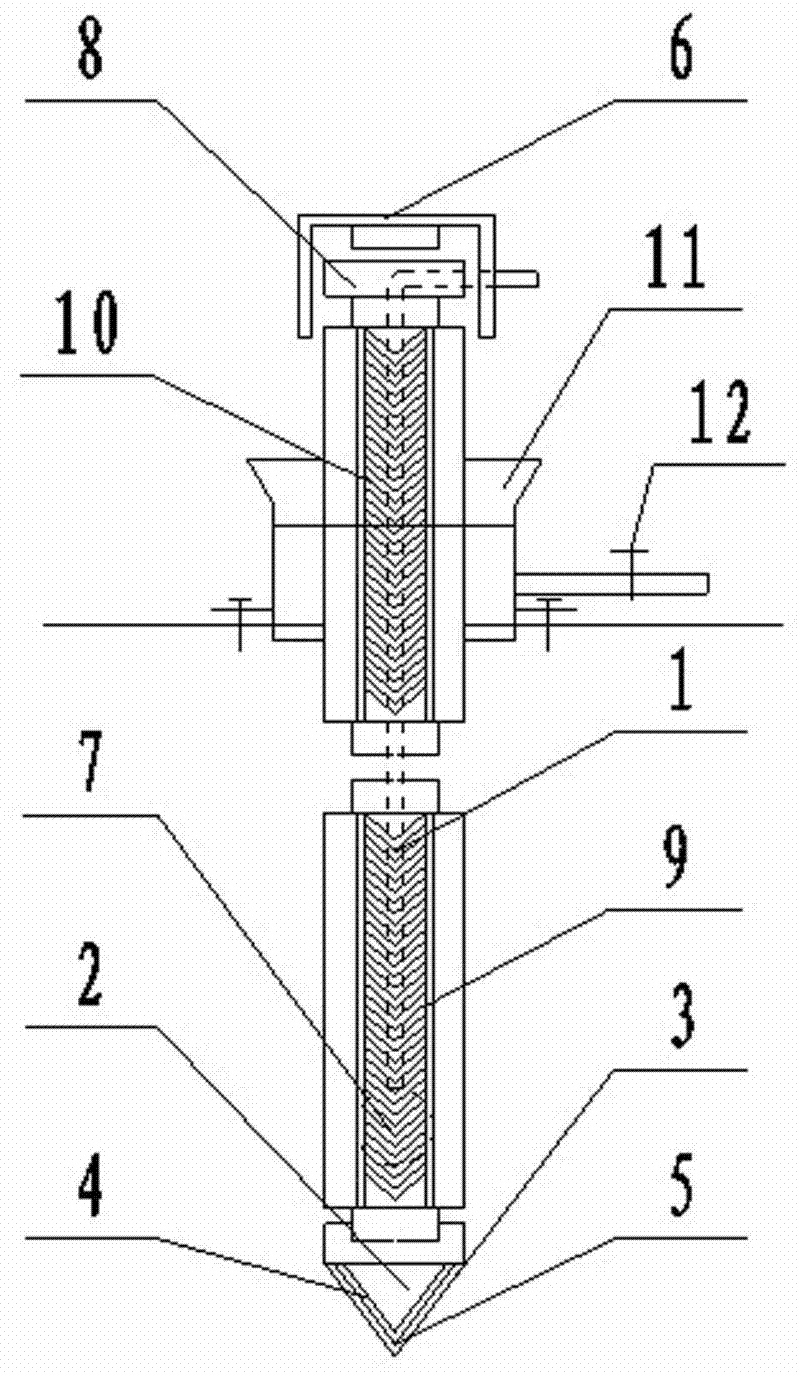

Construction method of prestressed pipe pile with vertical water discharge grooves

A technology of prestressed pipe piles and vertical drainage, applied in sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of reducing bearing capacity, polluting construction sites, etc., to reduce damage, prevent post-construction settlement, The effect of accelerating the drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The construction method of the prestressed pipe pile with vertical drainage grooves adopts the following steps: a. A plurality of drainage grooves 9 parallel to the axis are evenly distributed on the outer circumference of the prestressed pipe pile, and two adjacent drainage grooves 9 are arranged. A V-shaped groove 10 communicating with the drainage groove 9 is opened on the outer circumferential surface of the prestressed pipe pile between the grooves 9; The side wall of the water casing 11 is provided with a drainage pipe 1 communicating with it, and the drainage pipe 1 is provided with a control valve 12; c, penetrating the prestressed pipe pile along the opening of the water casing 11, and the pore water is under pressure at the same time Entering the V-shaped groove 10 and the drainage groove 9, the water in the V-shaped groove 10 is squeezed into the drainage groove 9, and the pore water in the drainage groove 9 rises to the water accumulation tube 11, and is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com