Ice breaking ship

An icebreaker and hull technology, applied in icebreakers, special purpose ships, ships, etc., can solve the problems of not too high ice breaking efficiency, damage to the hull structure, low ice breaking efficiency, etc. effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

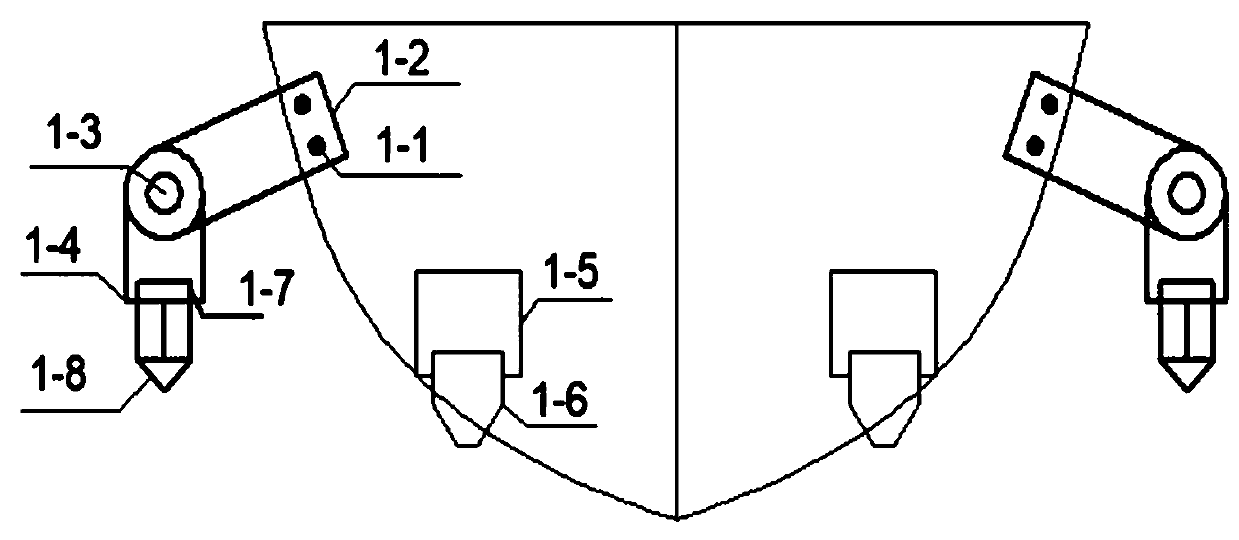

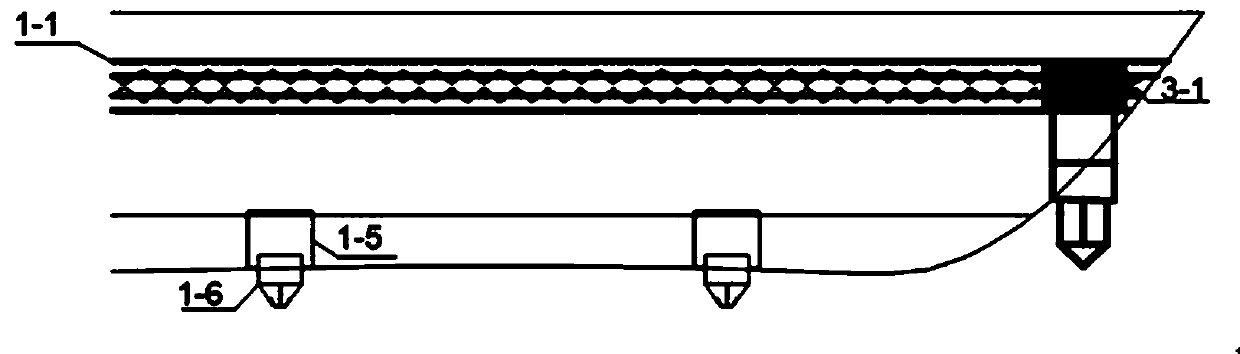

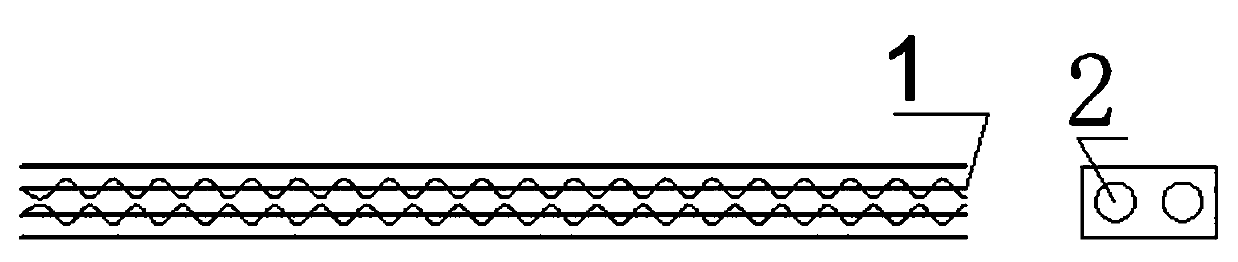

[0042] Through the second hydraulic device 1-5, the lengths of the four circular table structures 1-6 protruding from the bottom of the ship are consistent, that is, the four circular table structures 1-6 are located on the same level, because the second hydraulic device 1-5 It is a three-stage type, and the second hydraulic device 1-5 contracts up and down at the same speed. At this time, the contact area between the icebreaker and the ice surface is reduced, and the force of the unit contact surface is increased, and through the up and down contraction, the potential energy is used Effect, speed up the efficiency of ice breaking.

Embodiment 2

[0044] Through the second hydraulic device 1-5, since the second hydraulic device 1-5 is a three-stage type, the protruding length of the round table structure 1-6 of the bow from the bottom of the ship can be smaller than the length of the round table structure 1-6 of the stern. 6 length protruding from the bottom of the ship, so the gravity of the hull is concentrated on the stern part, thereby increasing the force of the ice layer at the stern by the circular platform structure 1-6, and increasing the ice-breaking efficiency.

Embodiment 3

[0046] Through the second hydraulic device 1-5, since the second hydraulic device 1-5 is a three-stage type, the length of the protruding circular platform structure 1-6 from the left side of the bottom of the ship is smaller than that of the stern circular platform structure 1 -6 length protruding from the right side of the bottom of the ship, the gravity of the hull is concentrated on the right part of the bottom of the ship, thereby increasing the force of the ice layer at the stern by the circular platform structure 1-6, and increasing the ice-breaking efficiency.

[0047] As can be seen from the above three embodiments, by adjusting the length of the round platform structure 1-6 from the bottom of the ship through 4 adjustments, the gravity of the ship can be concentrated on the front or rear or left or right of the ship, through the round platform structure 1 The up and down contraction movement of -6 uses the principle of gravitational potential energy to assist the ice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com