Louvered vertical axis resistance wind turbine

A shutter-type, resistance-type technology, applied in wind turbines, wind turbines at right angles to the wind direction, wind turbine control, etc., can solve problems such as wind turbine damage, large wind resistance area, and no deceleration or shutdown control settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

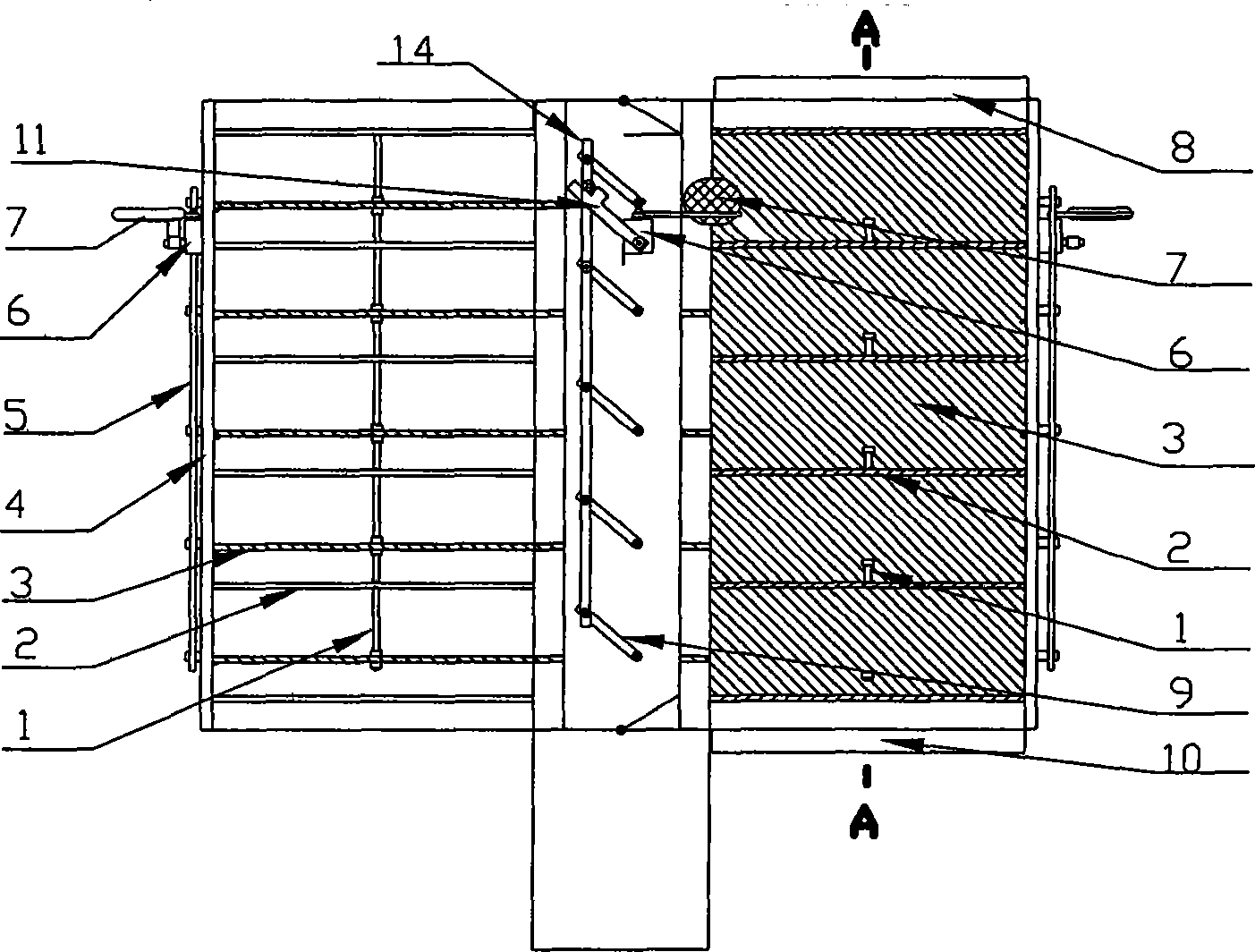

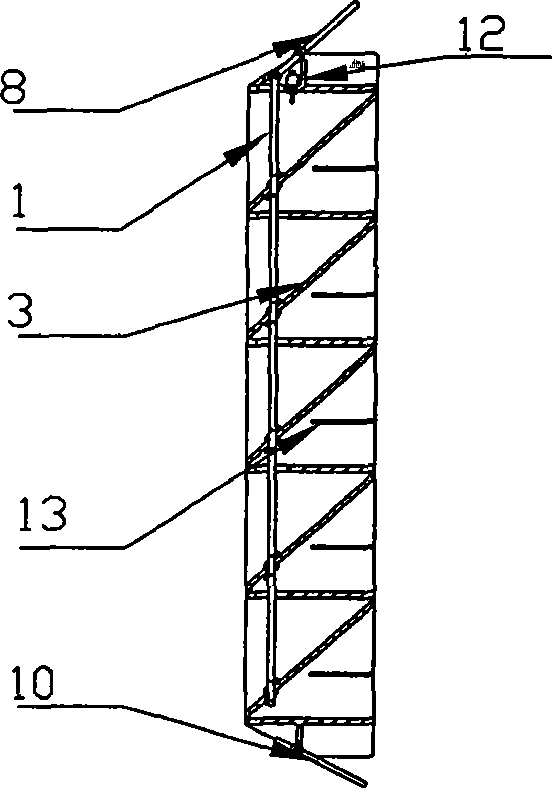

[0028] see figure 1 , figure 2 and image 3 , when a stationary wind turbine encounters a certain strength of wind, there is always a fan blade frame (4) at the position with the largest windward area, and its top moving plate (8) and bottom moving plate (10) are blown, while the top moving plate (8) Drive the moving plate (3) upward through the self-starting rod (1), and the moving plate (3) contacts with the upper and lower fixed plates (2) to form the largest wind resistance area. The fan blade frame (4) receives the thrust of the wind, The wind turbine realizes self-starting.

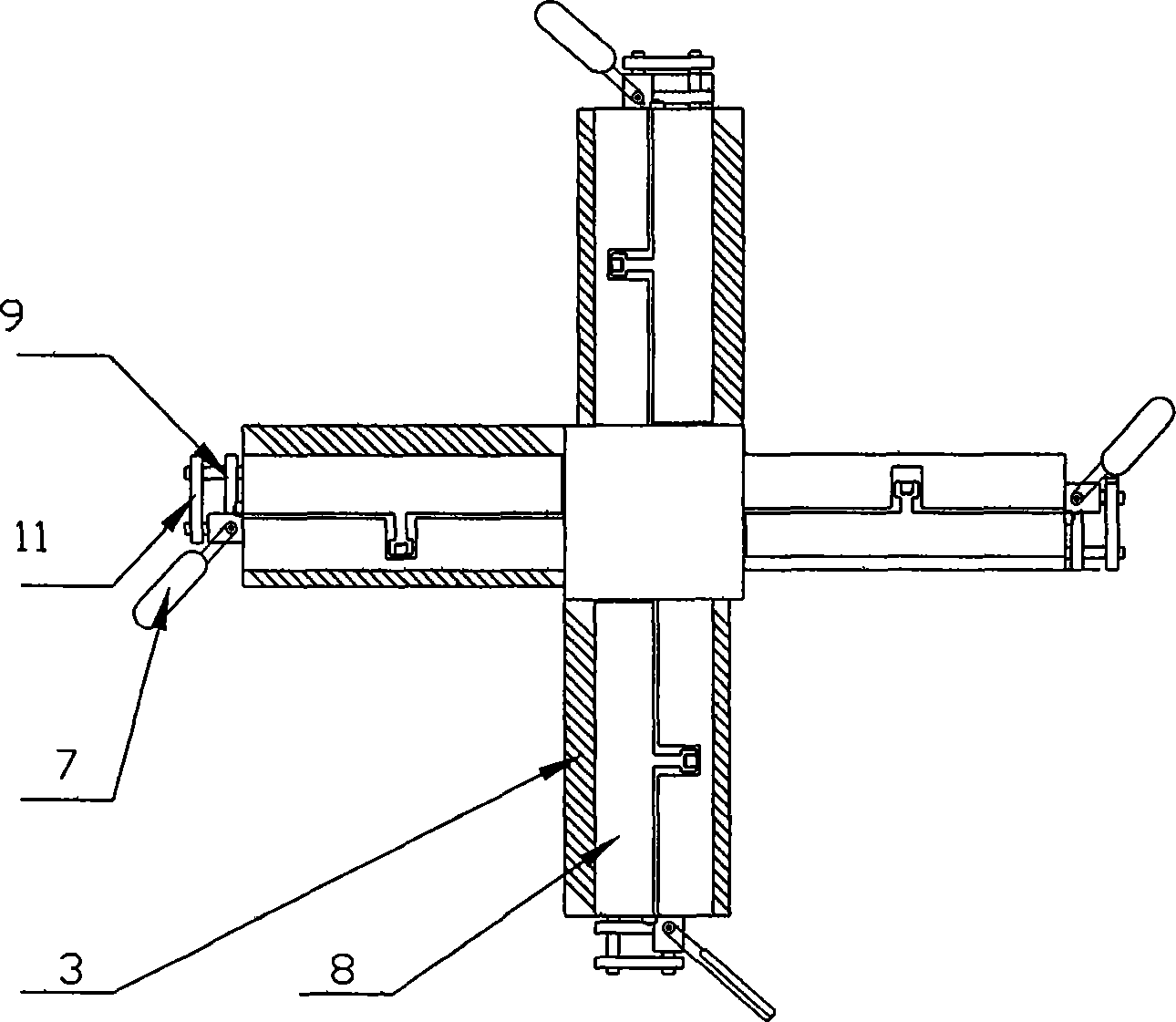

[0029] see Figure 5 , Image 6 , Figure 7 and Figure 8 , when a fan blade frame (4) rotates to a specific position during the rotation process, the first moving blade (7) installed on the outside of the frame is first erected by the wind, resulting in a larger wind resistance area, so it is blown to rotate for a certain Angle, the rotational torque generated by it becomes the vertical rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com