Protection device for water and material supply failures of emulsion explosive emulsifier and its control method

A technology of emulsified explosives and protection devices, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve problems such as large errors, insensitive responses, and potential safety hazards, so as to improve the accuracy of responses, improve intrinsic safety, and realize automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

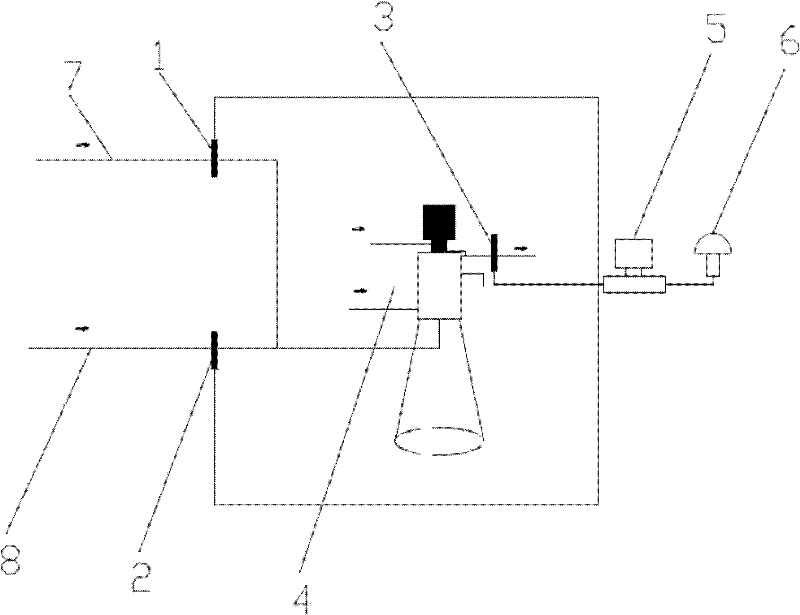

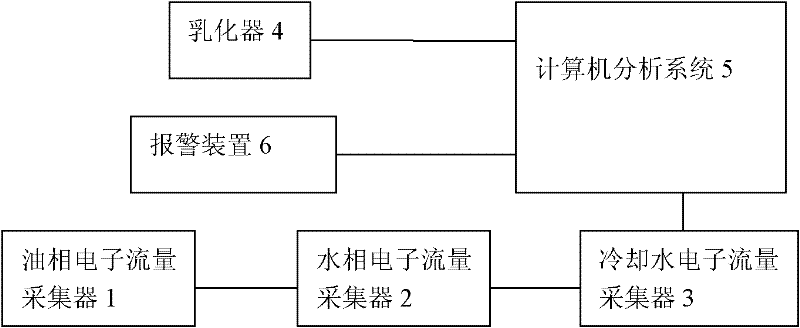

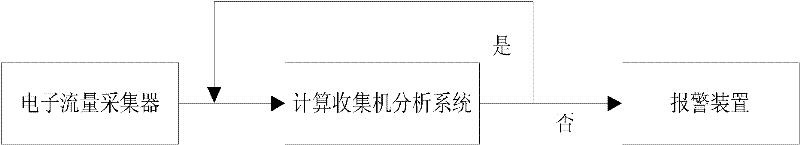

[0028] like figure 1 , 2 As shown, the emulsifier of the emulsified explosive of the present invention has a water cut-off and flow protection device, comprising an emulsifier 4, a computer collection and analysis system 5 and an alarm device 6, the emulsifier 4 is connected with a computer analysis system 5, and the computer analysis system 5 Connect with alarm device 6. The device also includes oil phase electronic flow collector 1, water phase electronic flow collector 2 and cooling water electronic flow collector 3 connected in series, oil phase electronic flow collector 1, water phase electronic flow collector 2 and cooling water electronic flow collector The flow collector 3 is connected in series with the computer analysis system 5; the oil phase electronic flow collector 1 is installed on the oil phase pipeline 7 for detecting the flow data of the oil phase pipeline; the water phase electronic flow collector 2 installed on the water phase pipeline, used to detect the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com