Double-output conjugate cam-connecting rod paper-transferring mechanism

A technology of conjugate cam and link mechanism, which is applied in the field of conjugate cam paper delivery mechanism and double output conjugate cam-linkage paper delivery mechanism, which can solve the problem of reducing the service life of the paper delivery mechanism, obvious impact of movement, and paper Unfavorable transmission accuracy and other issues, to achieve the effect of improving printing speed, accurate motion output, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

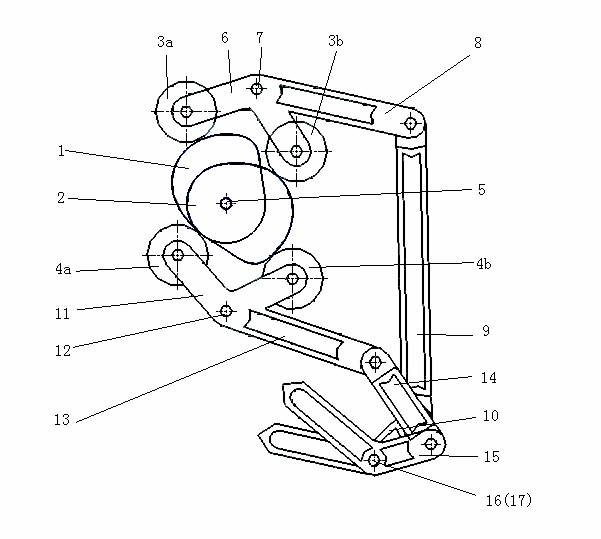

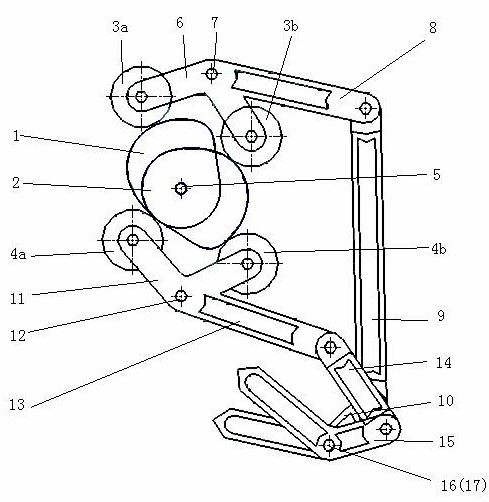

[0012] see figure 1 , double output conjugate cam-linkage paper delivery mechanism, including conjugate cam composed of main cam 1 and auxiliary cam 2 installed on transmission shaft 5, bow-shaped swing arm 6, transmission swing arm 8, connecting rod 9 and paper delivery The two ends of the swing arm 10 and the arcuate swing arm 6 are provided with two pressure rollers 3a, 3b, and the two pressure rollers 3a, 3b are respectively in contact with the outer circumferential surface of the main cam 1 and the auxiliary cam 2, and the transmission swing arm 8 One end of one end is fixedly connected with the middle part of the bow-shaped swing arm 6, the transmission swing arm 8 and the bow-shaped swing arm 6 are rotatably supported by a fulcrum shaft 7 and swing around the fulcrum shaft 7 together, and the other end of the transmission swing arm 8 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com