Open-end rotor spinning device and method for operating an open-end spinning device

A rotor spinning, open technology, applied in the direction of spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problem of reducing the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

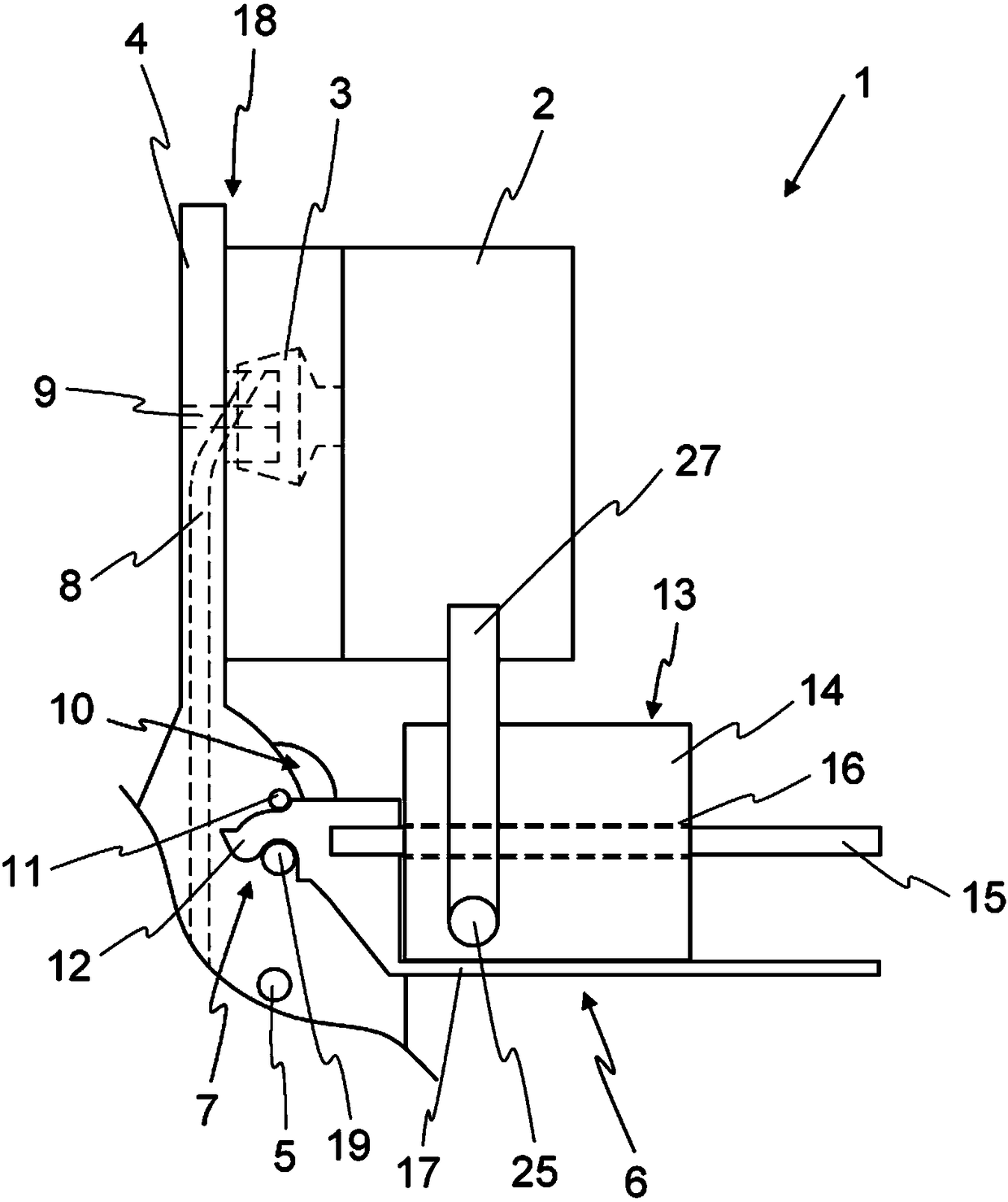

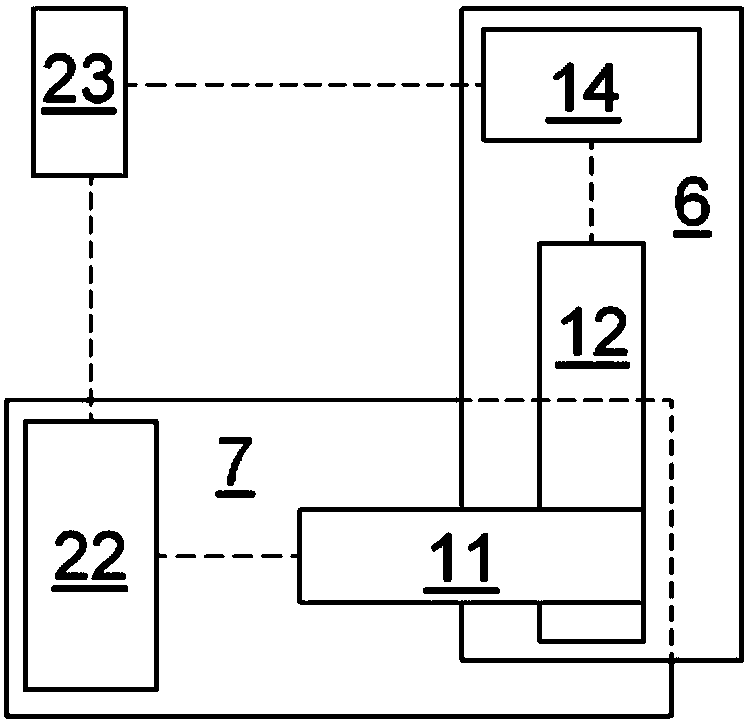

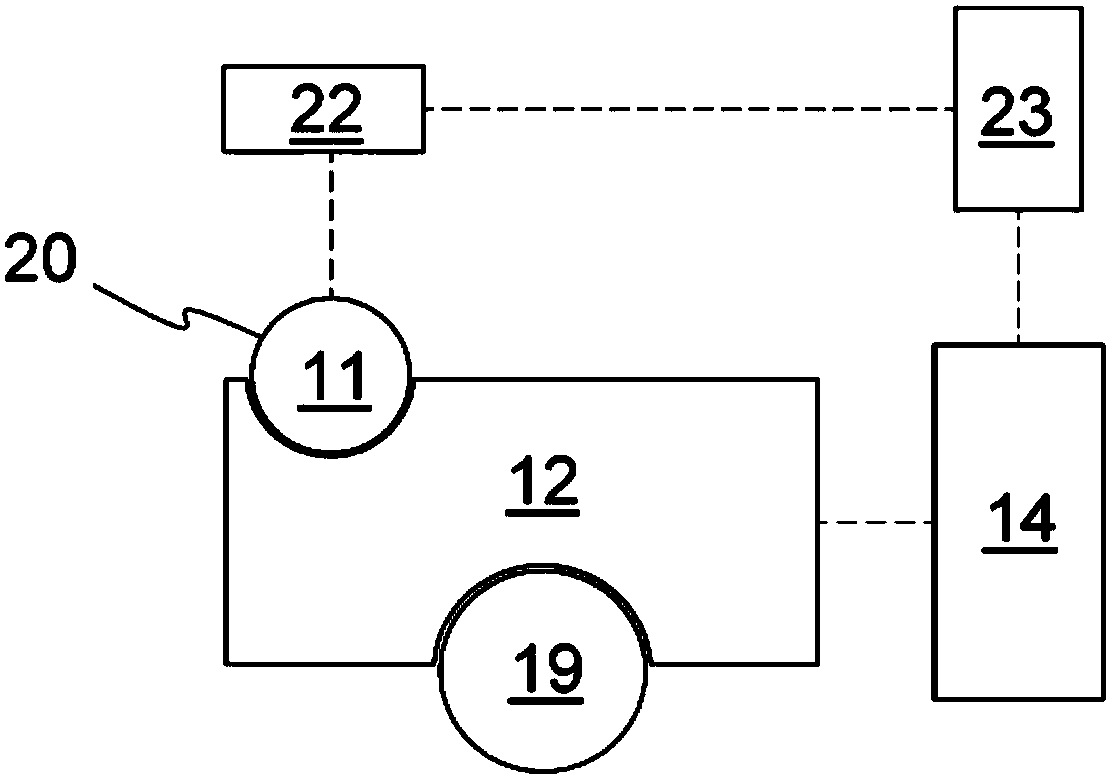

[0039] figure 1 The open rotor spinning device 1 is shown in a schematic sectional view. The open rotor spinning device 1 has a rotor housing 2 in which a spinning rotor 3 is rotatably mounted and rotates at an operating speed during operation of the open rotor spinning device 1 . The rotor housing 2 is covered by a cover part 4 , wherein the cover part 4 is arranged pivotably about a rotational axis 5 relative to the rotor housing 2 . The top cover part 4 is connected to the rotor housing 2 via a swing device 6 so that the top cover part 4 can be closed and opened. The swing device 6 is swingably connected to the rotor housing 2 through a box frame 27 . Here, the pivoting device 6 is connected to a cassette frame 27 via a second rotational axis 25 . Furthermore, the open rotor spinning device 1 has a locking device 7 for locking the cover part 4 . The locking device 7 and the pivoting device 6 are connected to each other.

[0040] The fiber material to be spun is fed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com