Totally-enclosed coal bunker formed by reconstructing wind shielding and dust suppression walls

A wind-shielding and dust-suppressing wall, fully enclosed technology, applied to storage devices, transportation and packaging, conveyors, etc., can solve problems such as waste, and achieve the effects of saving engineering costs, good dust-proof effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

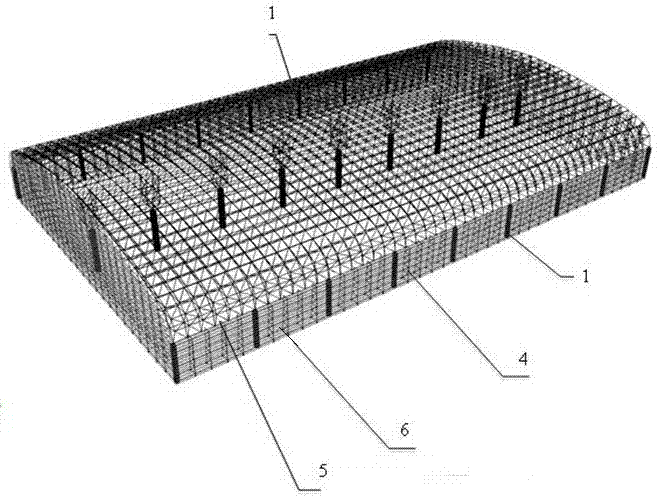

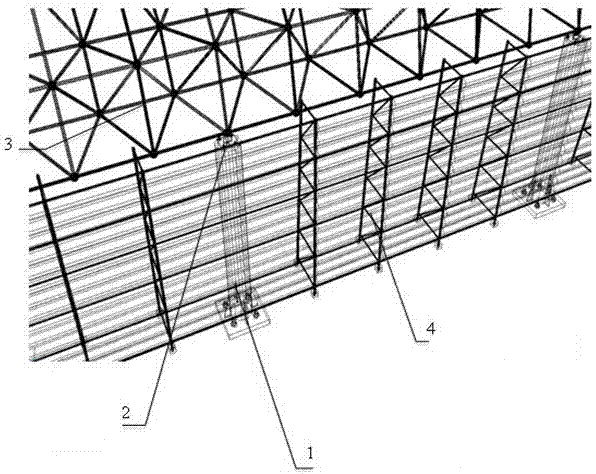

[0017] see figure 1 , a fully enclosed coal bunker transformed by using a wind-shielding and dust-suppressing wall, including a fully-enclosed coal bunker roof support column 1, a roof steel structure grid 3, a wind-shielding and dust-suppressing wall and its steel structure 4, a roof panel 5, and a wall Composed of ventilation panels 6, it is characterized in that: along the line of the wind-shielding and dust-suppressing wall, one or several steel structures 4 of the wind-shielding and dust-suppressing wall are removed at regular intervals, and the positions of the steel structures of the wind-shielding and dust-suppressing wall are removed to replace the whole The roof support column 1 is closed, and the roof support column 1 is also added along the center of the coal bunker to reduce the construction cost.

[0018] The roof support column 1 is composed of the support column foundation, the support column and the support column support 2. The height of the roof support colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com