Bucket-brushing system for closed-mouth bucket

A technology for brushing barrels and workbenches, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as unclean cleaning of the inner wall of the barrel, long cleaning time, and affecting the quality of brushing, etc., to achieve large-scale Large-scale production, short scrubbing time, and good cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

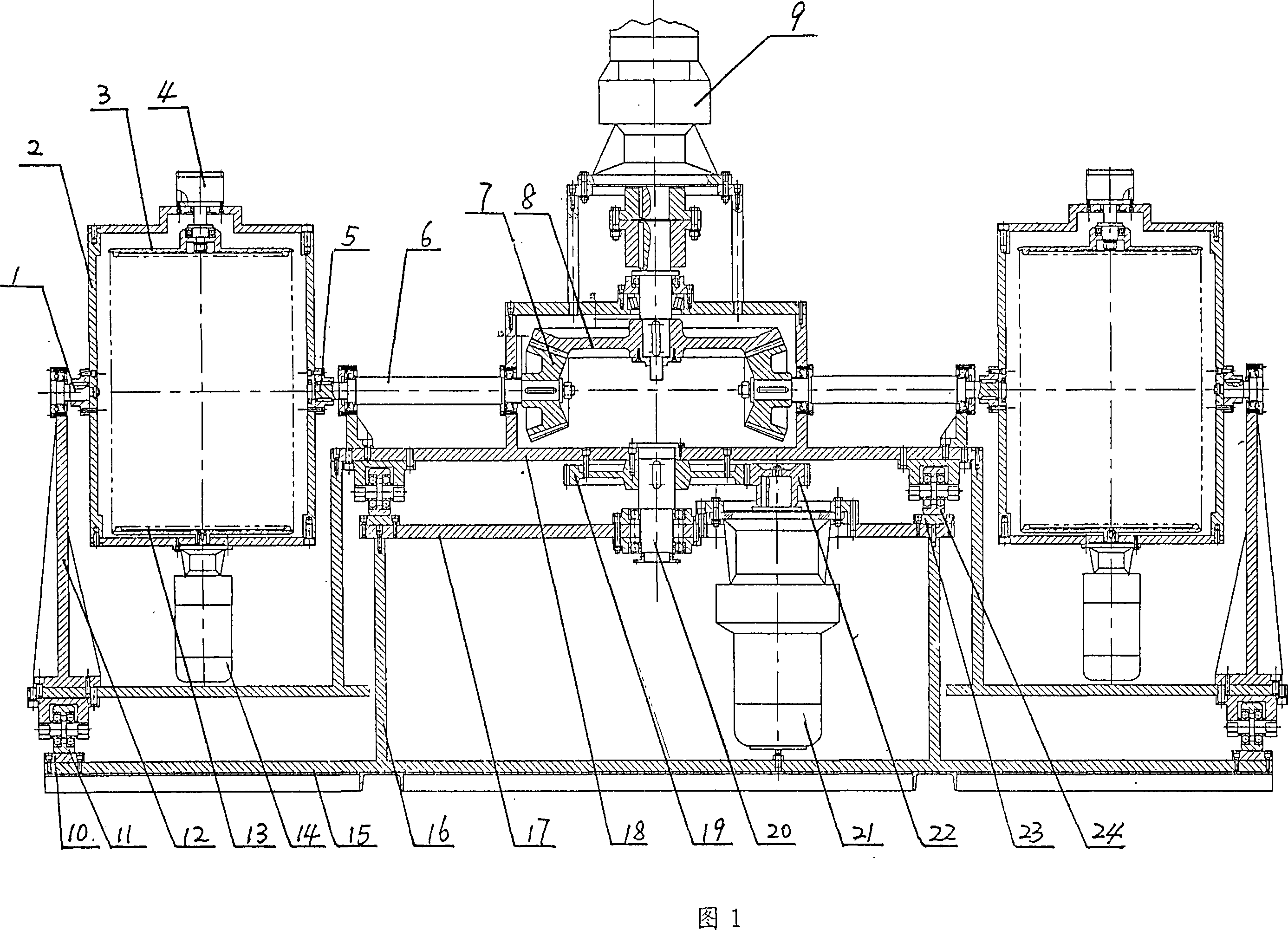

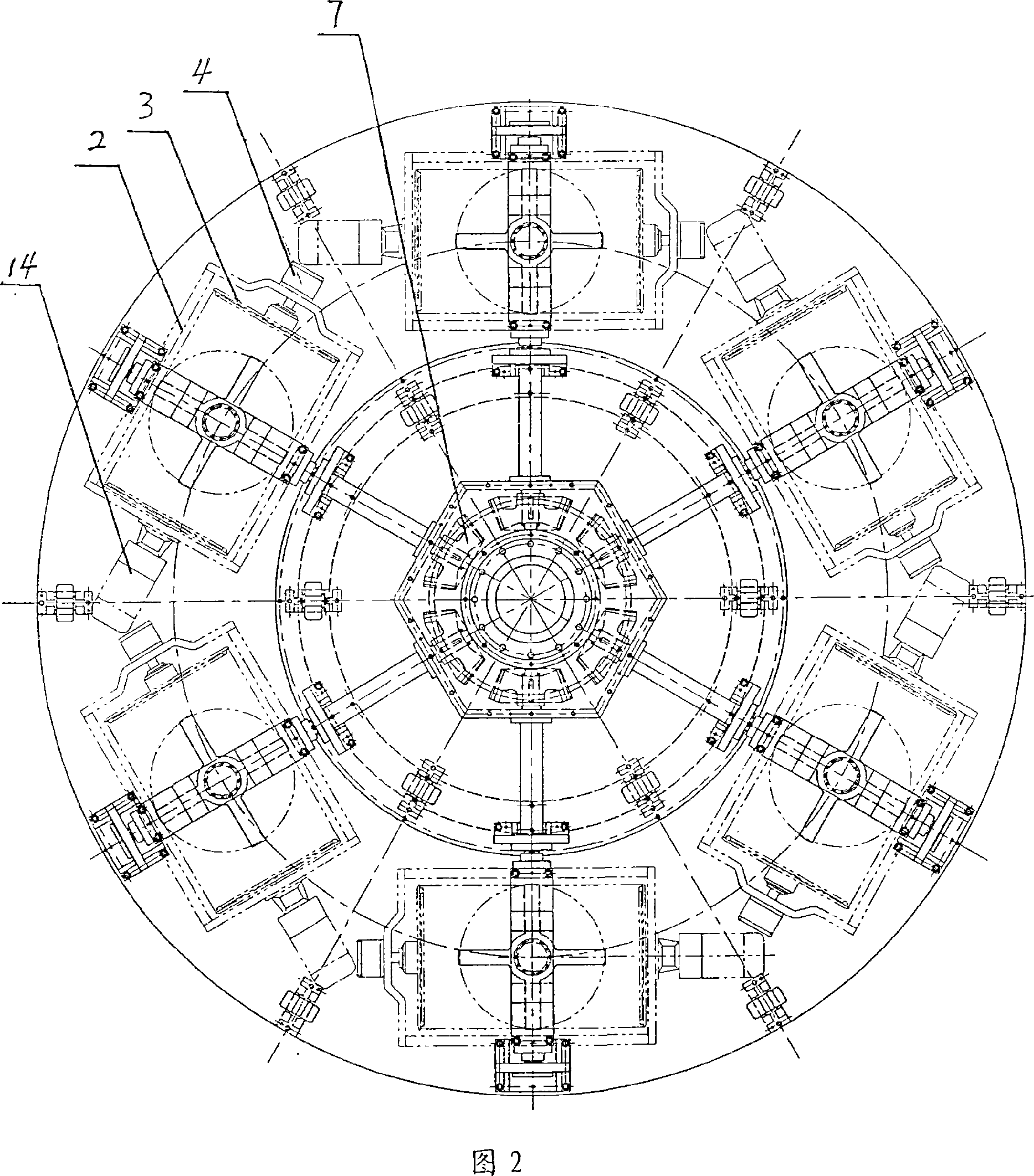

[0016] Fig. 1 is the schematic diagram of closed bucket brush bucket system of the present invention, comprises base 15, workbench 18 and at least one group of brush bucket units, base 15 is provided with workbench 18, is provided with at least one group of brush bucket units on the workbench, The bucket brush unit includes a bucket swing frame 2 and a bucket support 12, and the bucket support is connected with the workbench. One end of the bucket swing frame 2 is rotatably connected to the bucket bracket through the support shaft 1, and the other end is connected to the passive conical gear 7 fixed on the workbench through the connected support shaft 2 and transmission shaft 6, and the active conical gear meshed with the passive conical gear The bevel gear 8 is connected with the bucket swing motor 9 through a transmission mechanism and a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com