Water-spray brush regulator for dishwasher

A technology of water spray brush and regulator, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., and can solve the problems of large size and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

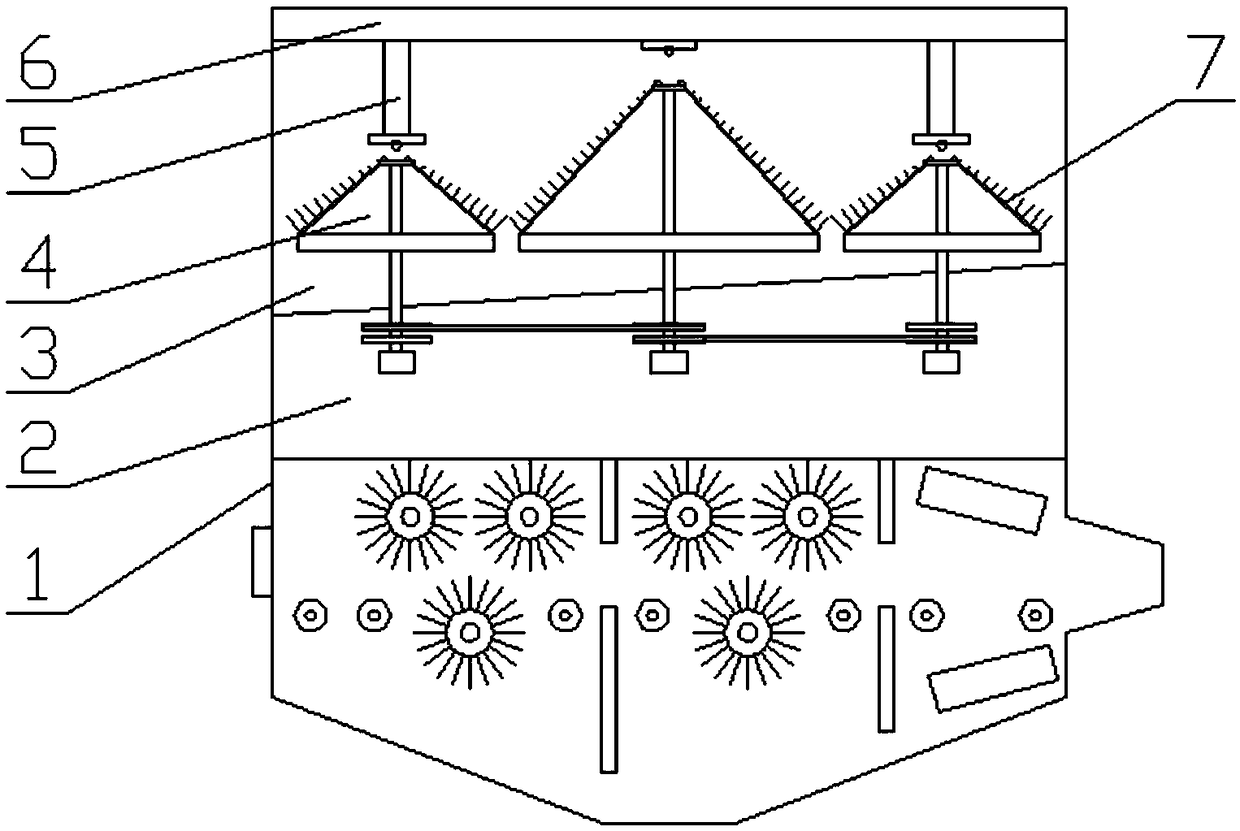

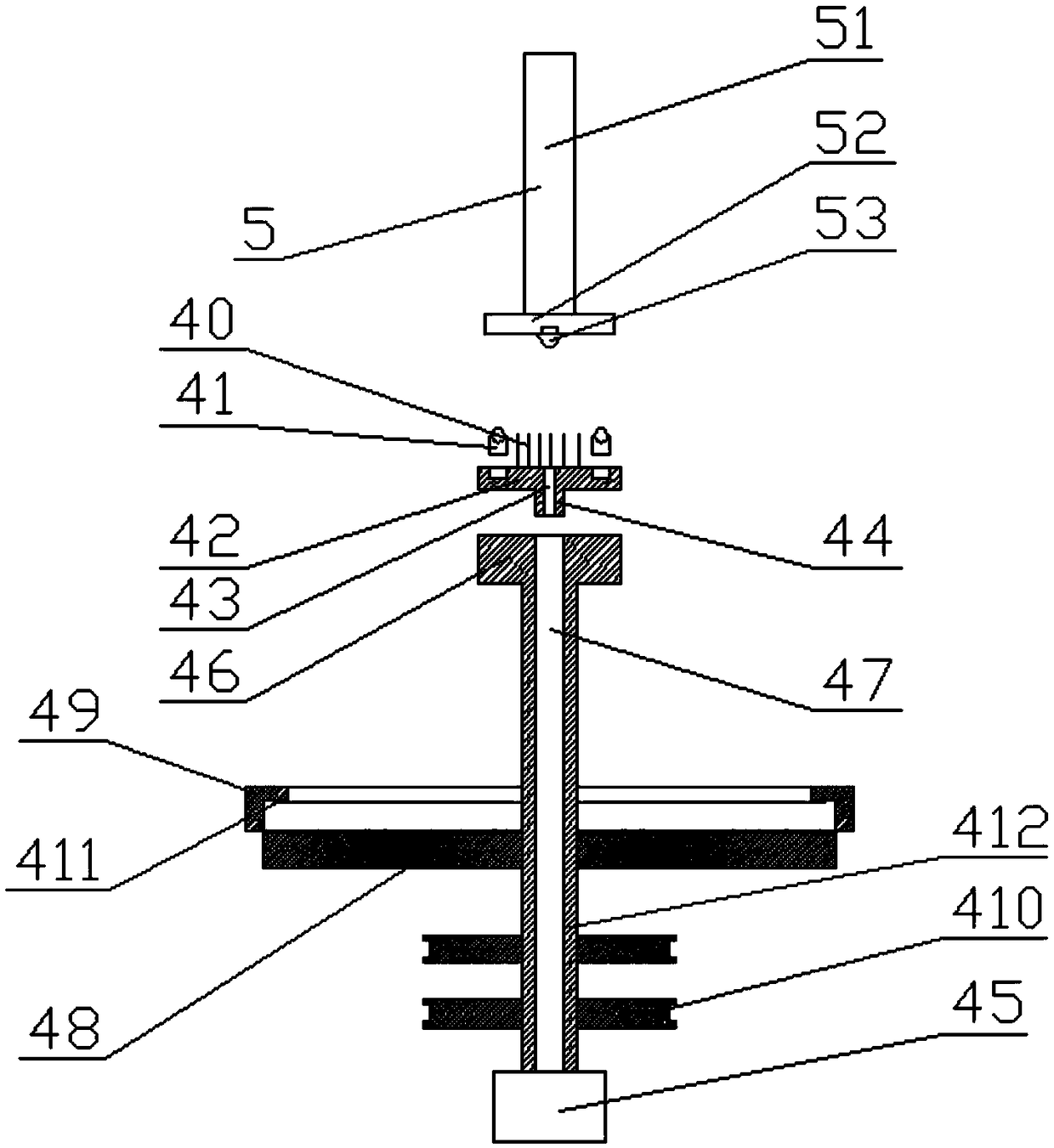

[0025] Such as Figure 1 to Figure 4 Shown; A kind of dishwasher water spray brush regulator, includes water spray brush regulator 4, and described water spray brush regulator 4 includes rotating shaft 412, power input part and cleaning part, and described power input The part is arranged at the lower end of the rotating shaft 412, and the cleaning part is arranged at the upper end of the rotating shaft 412; the lower end of the rotating shaft 412 is connected with a rotary joint 45, and the rotating shaft 412 is penetrated with a guide channel 47, and one end of the guide channel 47 is connected to the rotary joint 45, the other end of the guide channel 47 communicates with the cleaning part; the shaft 412 between the power input part and the cleaning part is sleeved with a bearing; the power input part includes at least two power wheels 410; The cleaning part includes a circular cleaning silica gel 7, a rotating plate 48, an L-shaped gland 49 with an L-shaped cross section, ...

Embodiment 2

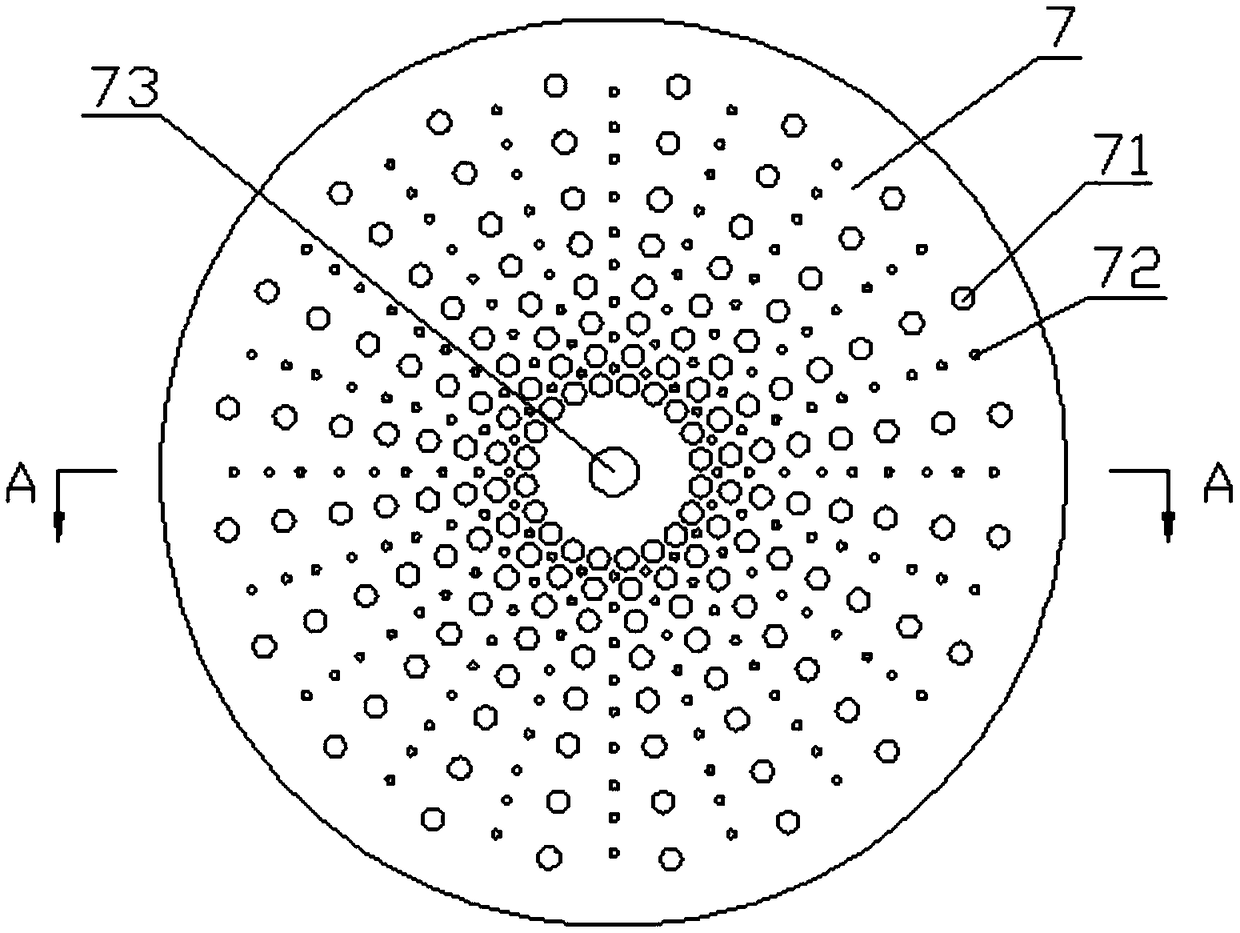

[0028] On the basis of Example 1, several water outlet holes 72 are uniformly arranged on the circular cleaning silica gel 7; metal ferrules are sintered on the water outlet holes 72; upper bristles 40 are arranged on the upper pressing plate 42; Said cross-section is that L-shaped gland 49 cooperates with rotating plate 48 to compress the side of the outer circumference of circular cleaning silica gel 7 with bead 411; the thickness of the center of said circular cleaning silica gel 7 is B, and 7 The thickness of the outer edge is C, the thickness of B is 1.0 mm to 3.5 mm, the thickness of C is 3.5 mm to 6.0 mm; the thickness of B is 2.5 mm, and the thickness of C is 4 mm.

[0029]Evenly arrange several water outlet holes 72 on the circular cleaning silica gel 7, so that the cleaning water is sprayed out through the water outlet holes 72, so that the wall of the bowl is washed, and the water outlet holes 72 are not easy to be too large, depending on the number, but the diameter...

Embodiment 3

[0031] On the basis of embodiment 2, it also includes a pressing device 5, which is arranged directly above the cleaning part of the water spray brush regulator 4; the pressing device 5 includes a fixed rod 51, an adjusting plate 52 and bolts, the adjusting plate 52 is connected to one end of the fixed rod 51 by bolts, the adjusting plate 52 is provided with a waist-shaped countersunk head, and the bolt is connected to the fixed rod 51 through the waist-shaped countersunk head; The adjusting plate 52 is provided with an upper bull's-eye bead 53 , and the upper bull's-eye bead 53 cooperates with the cleaning part of the water spray brush regulator 4 .

[0032] Press and limit the bottom of the bowl upside down on the water spray brush regulator 4 by the upper bull's eye 53 on the pressing device 5, so that the water spray brush regulator 4 will be carried away in the middle of the rotation process, The upper bull's-eye 53 and the lower bull's-eye 41 cooperate to limit and press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com