Dragging type middle-sized disc harrow

A disc harrow, drag-type technology, applied in the direction of harrow, application, agriculture, etc., can solve the problems of low adjustment efficiency, complex structure, high work intensity, etc., and achieve the effect of prolonging the service life, convenient and quick operation, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

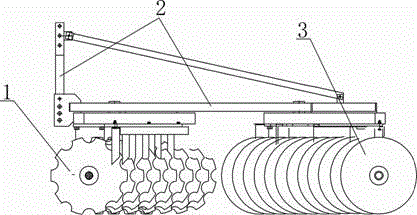

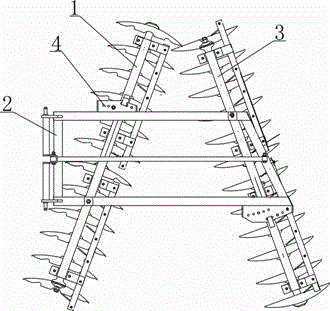

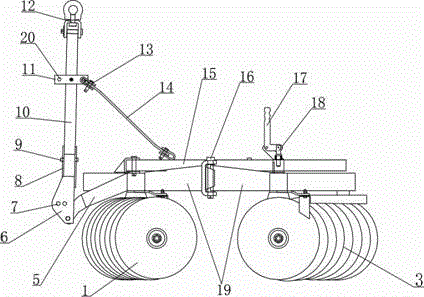

[0014] see figure 2 , 3 As shown, the present invention discloses a drag-type medium-sized disc harrow, which includes a front rake group 1 and a rear rake group 3 composed of a main shaft, rake blades, intermediate tubes, bearing assemblies and beams, both of which are fixed at the same end There is an articulated arm 10 extending to the middle, and the top ends of the two articulated arms 10 are hinged by a rotating shaft 16. The above structure ensures that the front rake group 1 and the rear rake group 3 can rotate relative to each other, and then the deflection angle between them can be adjusted; the front rake group 1 and the rear rake group 3 is further provided with a longitudinal beam 15, the front end of the longitudinal beam 15 is hingedly connected with the front rake group 1, and the middle and rear part of the longitudinal beam 15 is provided with several vertical The positioning hole 21 of the rear rake group 3 is provided with an adjusting pin 18 that coopera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com