Traction type multi-functional residual film cleaning and recovering machine

A multi-functional, traction technology, applied in the direction of collectors, agricultural machinery and implements, shovels, etc., can solve the problems of changing soil, blocking the development of plant roots, permeability, ecological environment damage, etc., to achieve good grip effect, Guaranteed effect of residual film recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

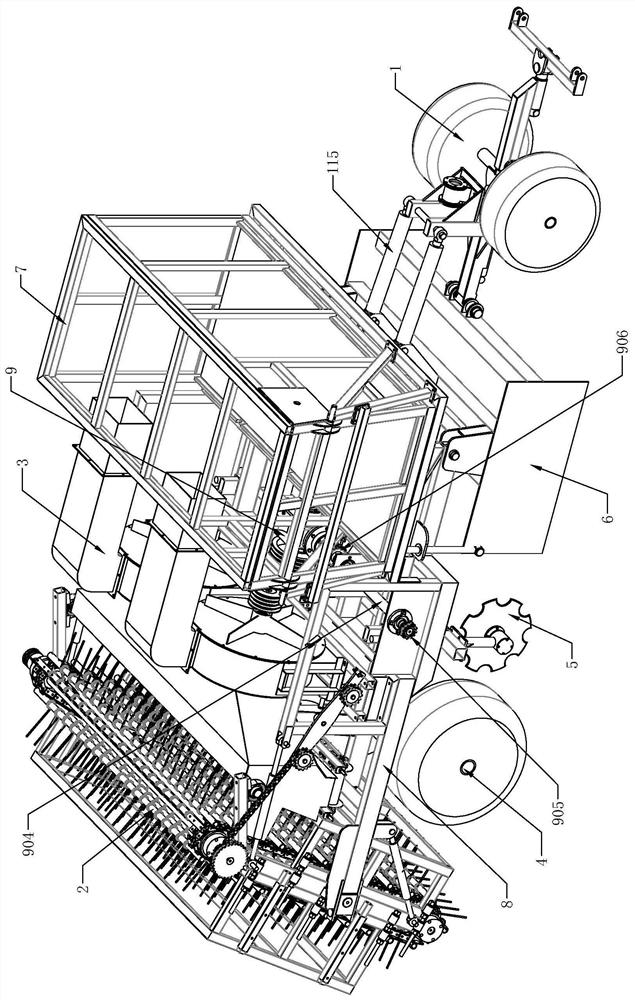

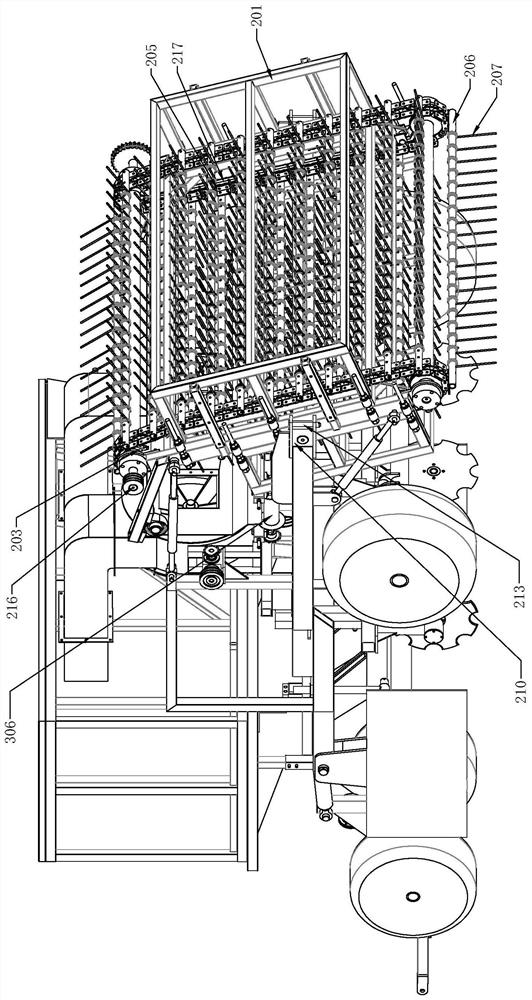

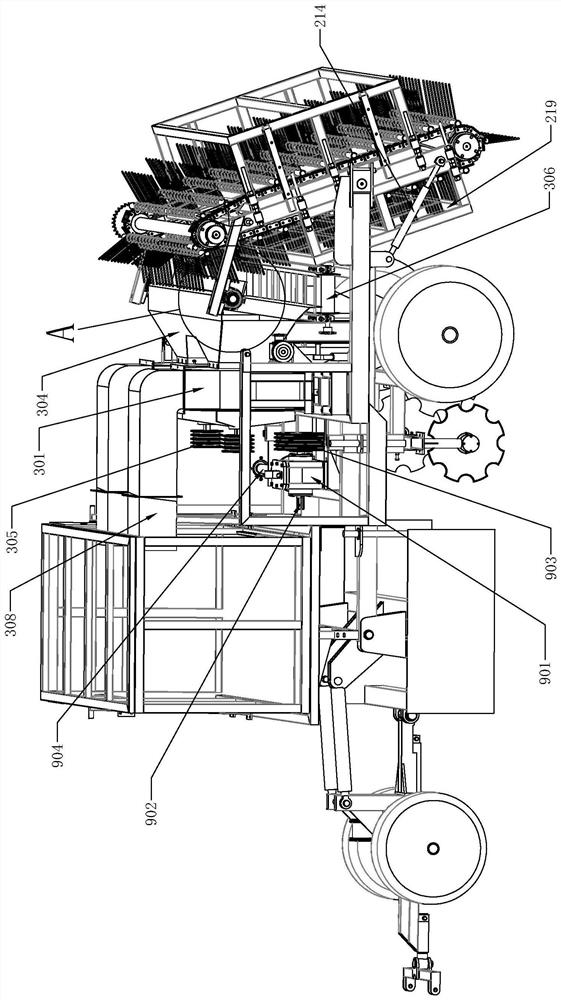

[0036] like Figure 1-14 As shown, a traction-type multifunctional residual film cleaning and recovery machine includes a traction device 1, a spring tooth chain rake device 2, a drainage and sorting device 3, a lifting wheel 4, a film-breaking disc harrow 5, and a rotary tiller 6 And the film recovery box 7, the traction device 1 is connected to the front end of the frame 8 in rotation, the rear end 9 of the frame 8 rotates and supports the inclined elastic tooth chain rake device 2, the upper end of the elastic tooth chain rake device 2 The discharge end is connected with the drainage and sorting device 3 The feed end is connected, and the drainage and sorting device 3 is installed in the middle of the upper surface of the frame 8. The bottom of the frame 8 supports the lifting wheels 4 driven by the lifting hydraulic cylinder, and the bottom of the frame 8 on the front side of the lifting wheels 4 is fixed. There are two rows of membrane-breaking disc harrows 5 arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com