Disc harrow axle base

A disc harrow and shaft seat technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problem of not being able to bear axial and radial forces, the anti-mud effect is not very ideal, and the durability is not good Meet the requirements and other issues, achieve the effect of reducing maintenance, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

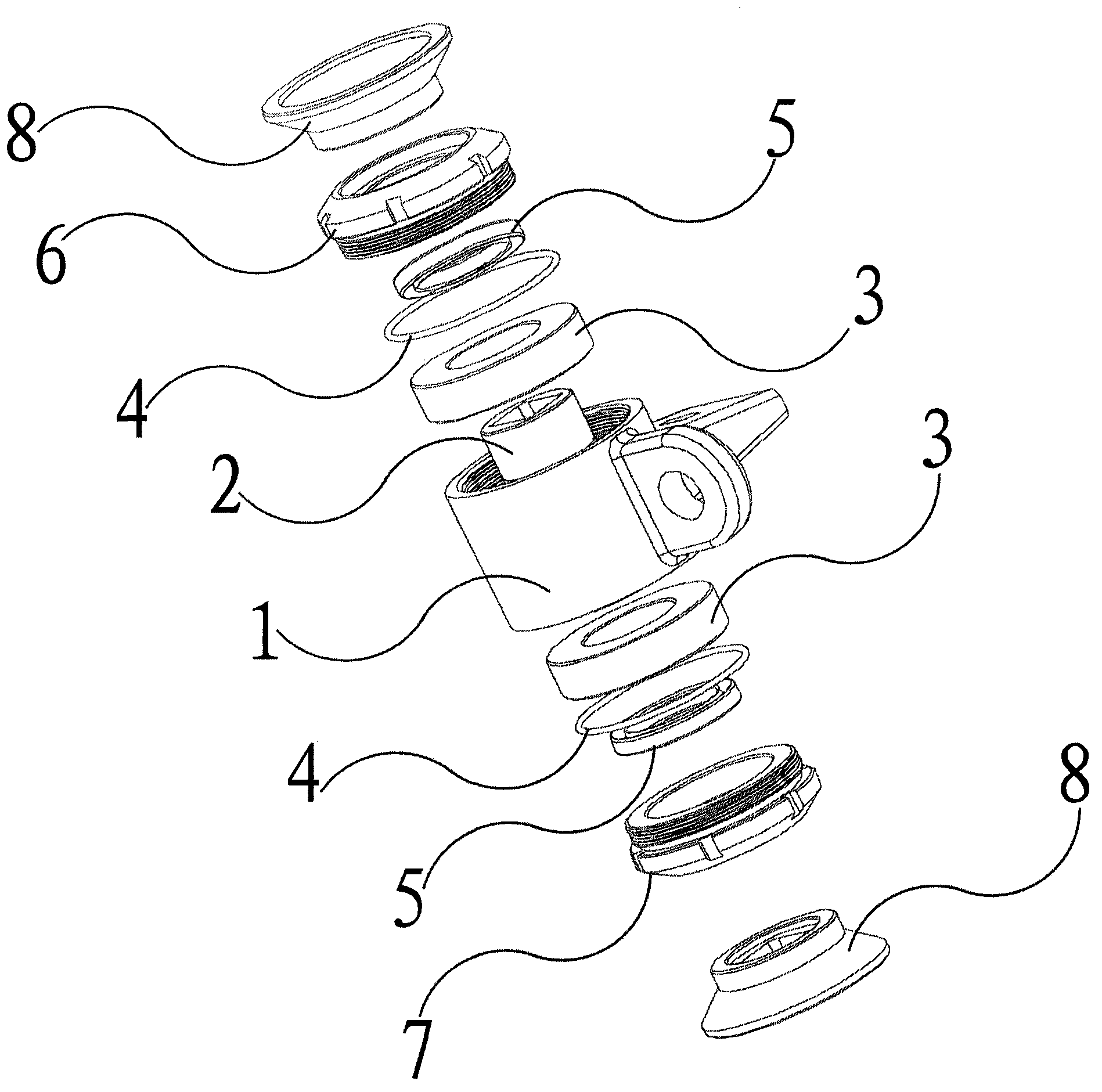

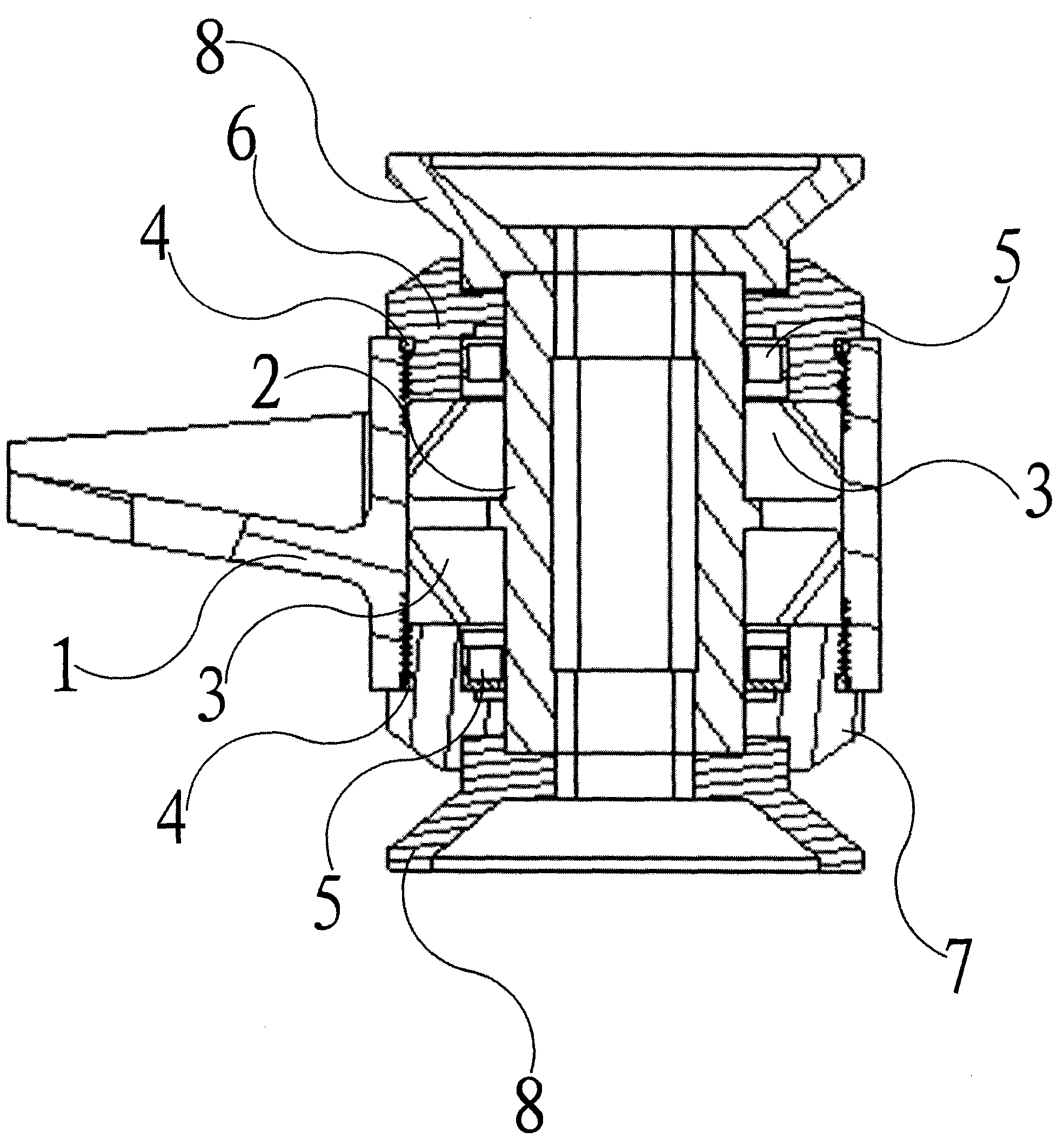

[0012] Such as figure 1 , figure 2 As shown, the shell 1 is provided with ears connected with the rake body, both ends of the inside of the shell 1 are provided with positive and negative threads, the inside of the shell 1 is provided with a mandrel 2, and the middle of the mandrel 2 is provided with On the convex edge, tapered roller bearings 3 are respectively installed on both sides of the convex edge, and the tapered roller bearings 3 are assembled opposite to each other. Double oil seals 5 are installed on the inner side of the left-handed gland 6 and right-handed gland 7, and the sealing ring 4 is installed on the outer side, which are then set on the mandrel 2 and connected with the tapered roller bearings 3 respectively; 7 is screwed on the front and back threads of the housing 1. On the left-handed gland 6 and the right-handed gland 7, half-intermediate pipes 8 are respectively installed, and the two ends of the half-intermediate pipe 8 and the mandrel 2 are made b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com