Seedbed preparation implement having rotary disc with adjustable gang angle

a technology of gang angle and seedbed, which is applied in the direction of adjusting devices, agricultural machinery, agricultural tools and machines, etc., can solve the problems of inability to adjust “infinitely” and difficult or imprecise adjustments, and no multi-functional seedbed preparation implements have been used with gang angle adjustable discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. Resume

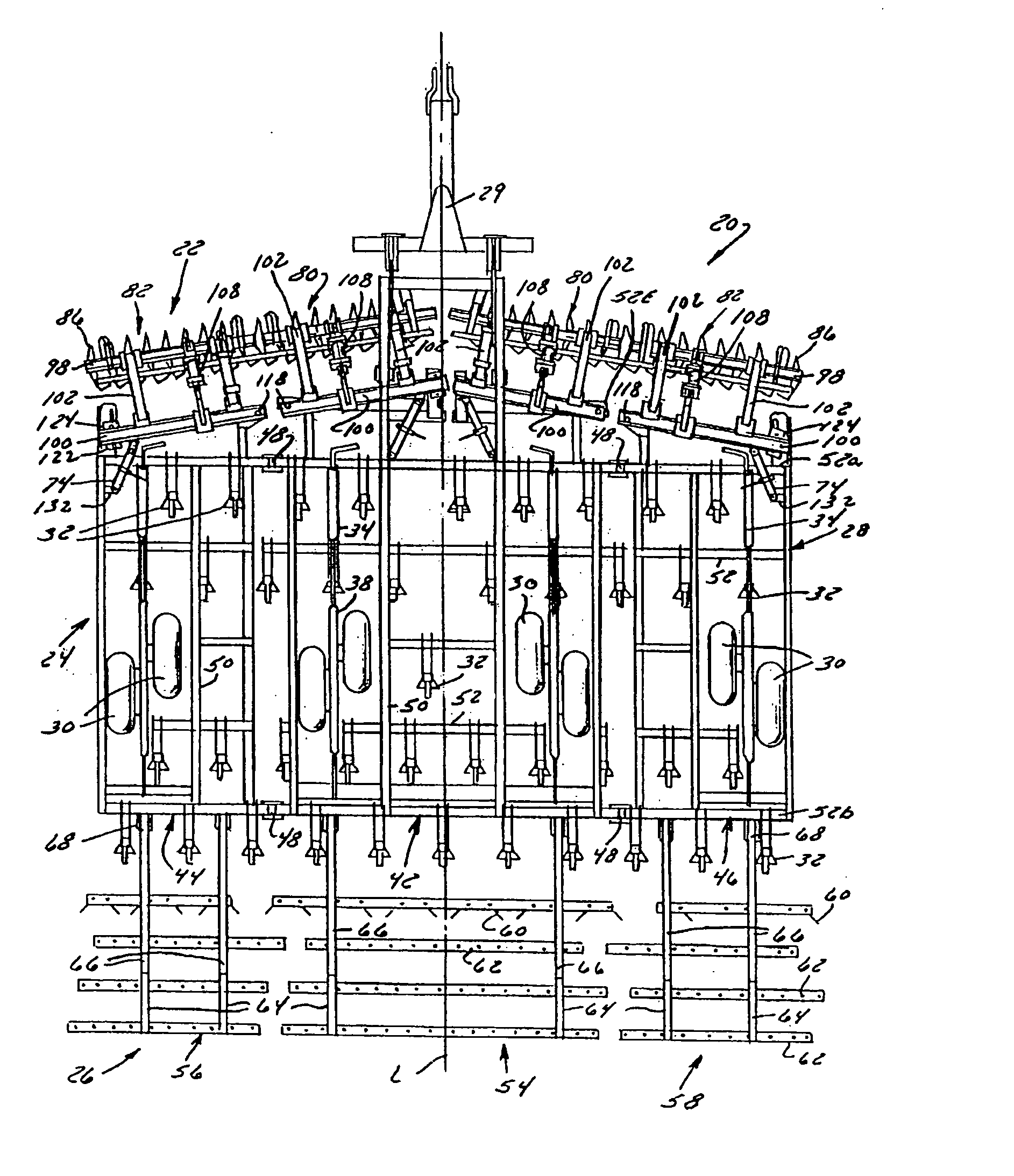

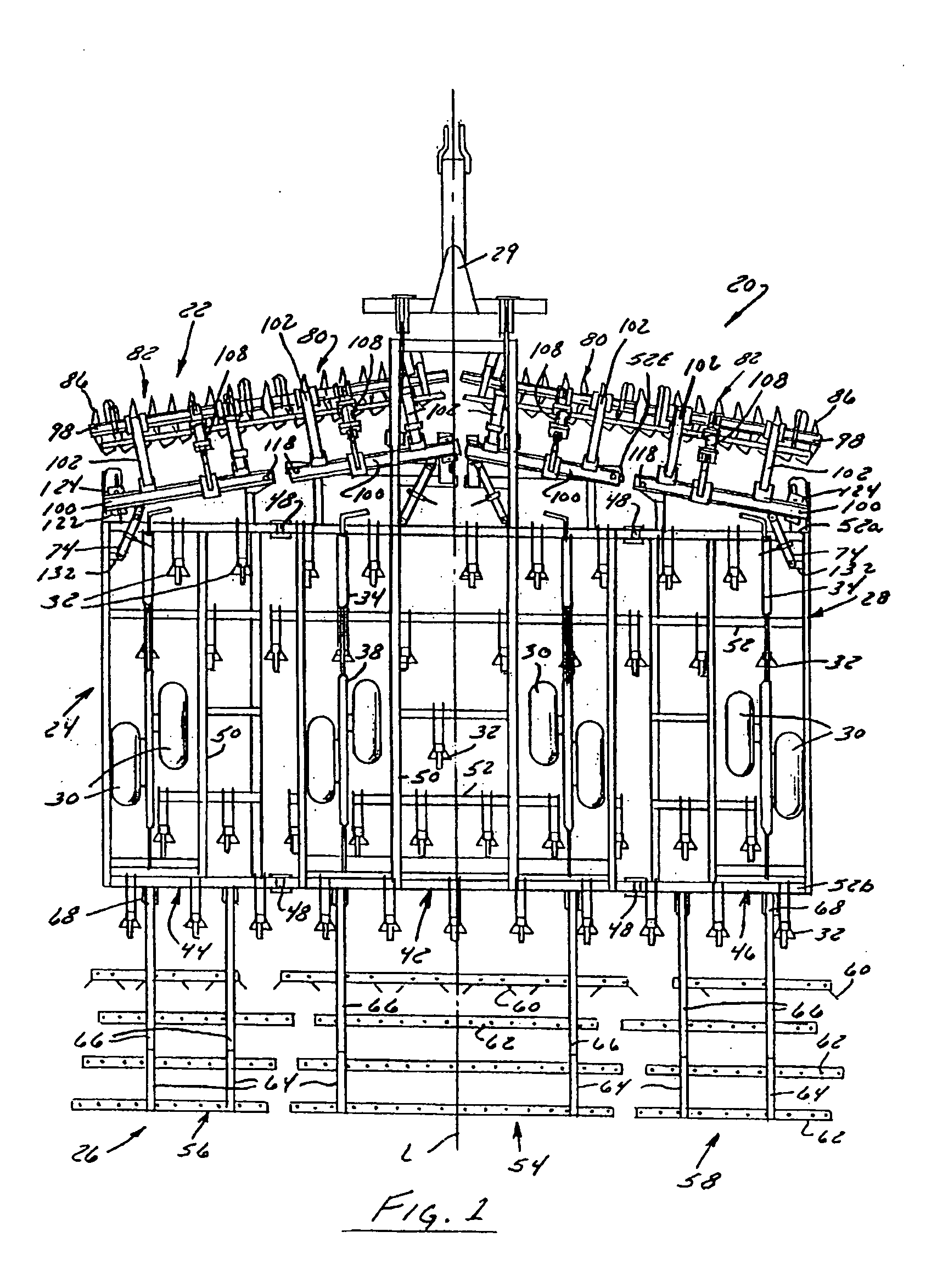

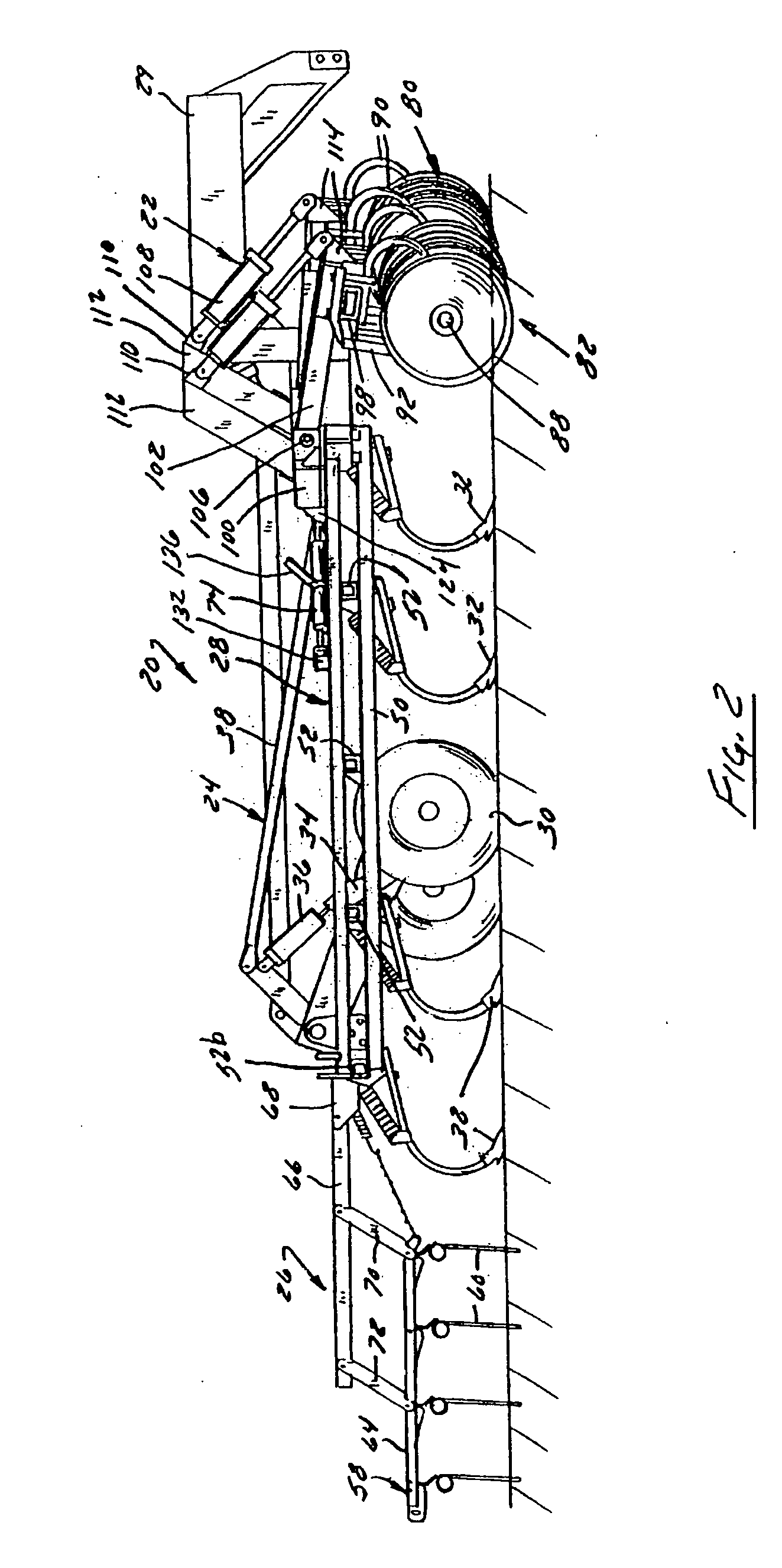

[0041] Pursuant to the invention, a disc gang is provided that is well suited (but not exclusively suited) for use as part of a multifunctional seedbed preparation implement and that is configured to permit a gang angle of the disc gang to be adjusted to accommodate different operating conditions and / or to obtain different tillage characteristics. In one embodiment, the disc gang includes a frame mounted on a mainframe of a primary tillage implement such as a cultivator. The frame includes a main beam mounted on the implement's mainframe and a disc support beam connected to the main beam and supporting a plurality of rotating discs. The gang angle can be infinitely adjusted through a designated range of, e.g., about 5° to about 10°, by pivoting one end of the disc gang about a vertical pivot axis while permitting another end portion of the disc gang to slide along a slotted plate or other unsegmented support surface for that end portion. The disc support beam may also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com