Elastic polishing device and method for special-shaped workpiece

A special-shaped workpiece, elastic technology, applied in the field of elastic polishing equipment, can solve problems such as narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

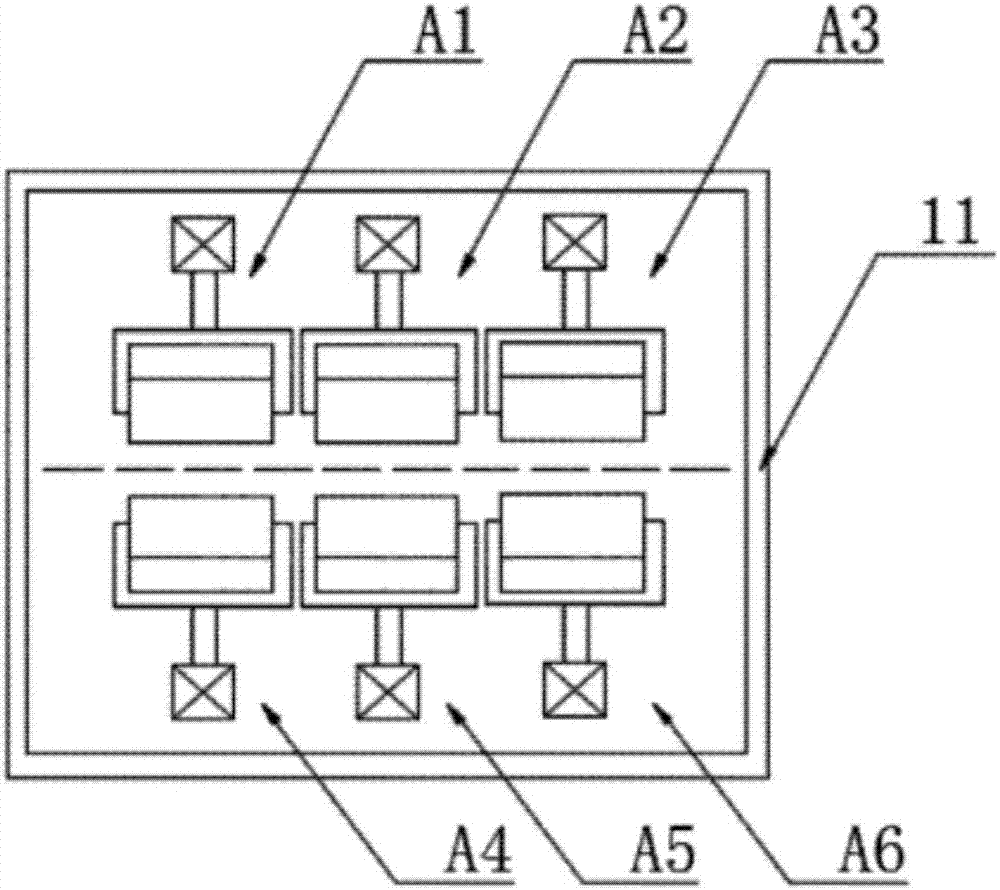

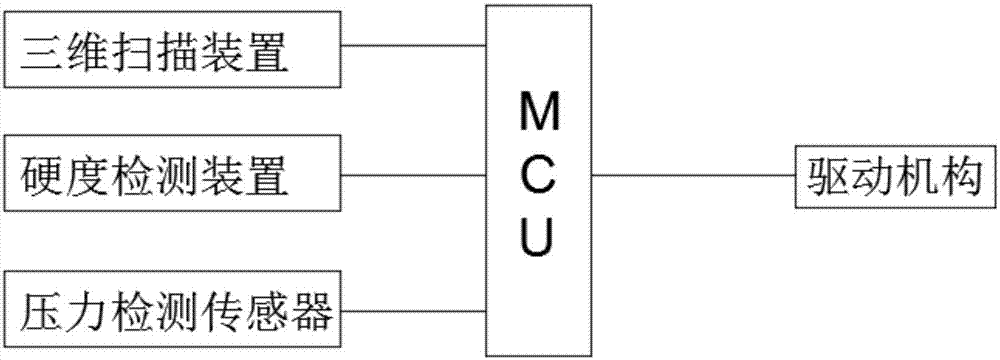

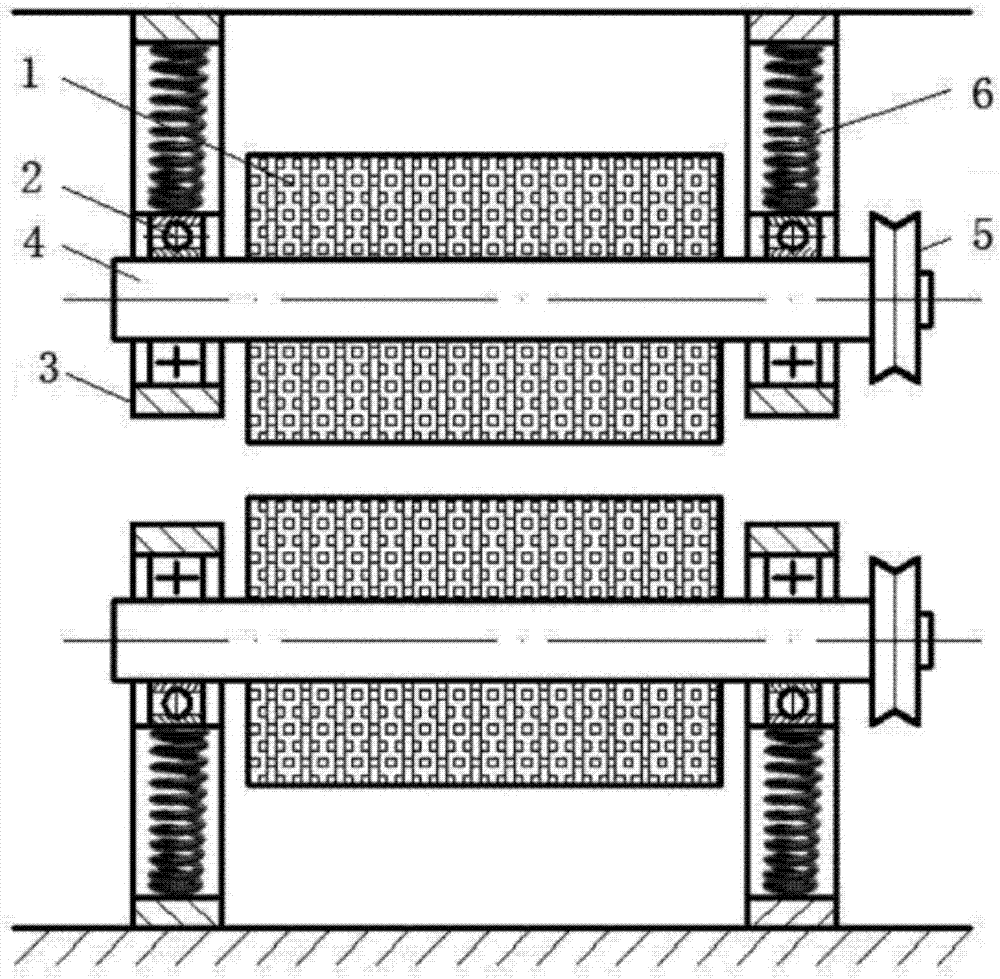

[0032] Such as Figure 1 to Figure 4 As shown, an elastic polishing device 11 for a special-shaped workpiece includes a pedestal, a main control circuit storing three-dimensional data of the special-shaped workpiece 7, at least 4 polishing units and a driving mechanism equal to the number of polishing units, and the polishing unit The two sides of the pedestal are arranged symmetrically to form a line of symmetry, and the driving mechanism drives the polishing unit close to or away from the line of symmetry under the control of the main control circuit to adapt to different sizes of different parts of the workpiece. The special-shaped workpiece 7 is clamped and pushed into the polishing unit by manual or mechanical hands to perform in-and-out and rotary motion polishing. The special-shaped workpiece 7 is metal, plastic or ceramics. There are an even number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com