Anti-impact rotating plate feeding machine

A technology of rotating plate and feeder, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of difficulty in adjusting the feeding angle and the inability to control the feeding amount, so that the feeding amount can be adjusted at any time and the equipment is environmentally friendly Energy-saving and high-efficiency, the effect of increasing the rotation angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

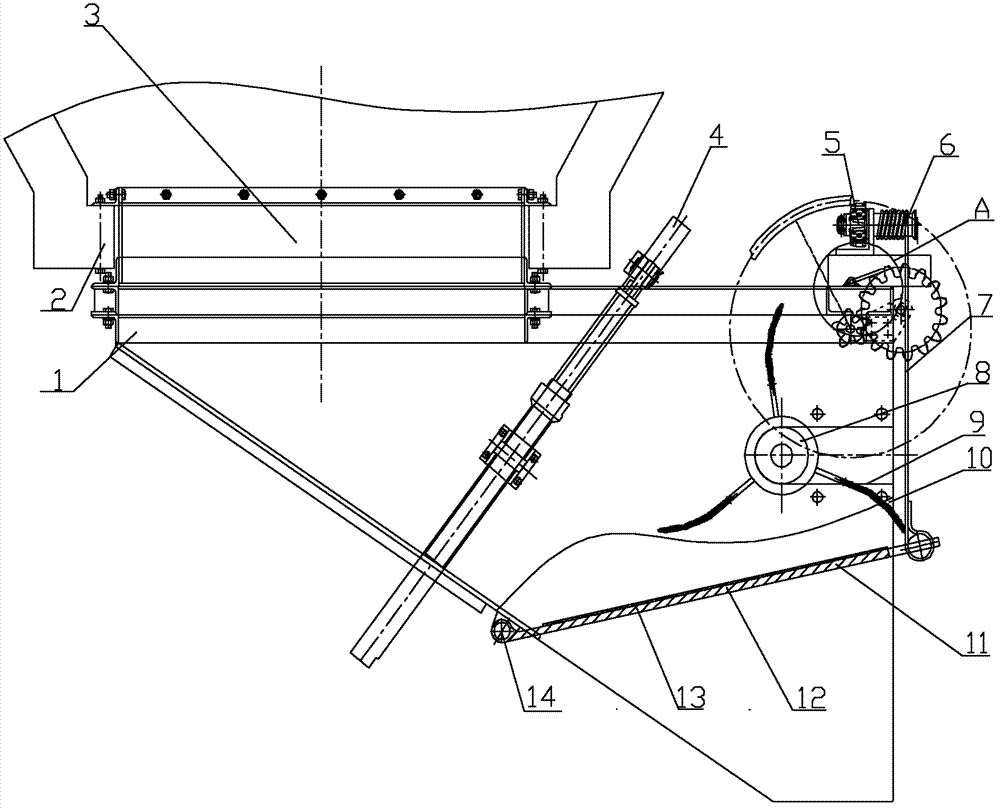

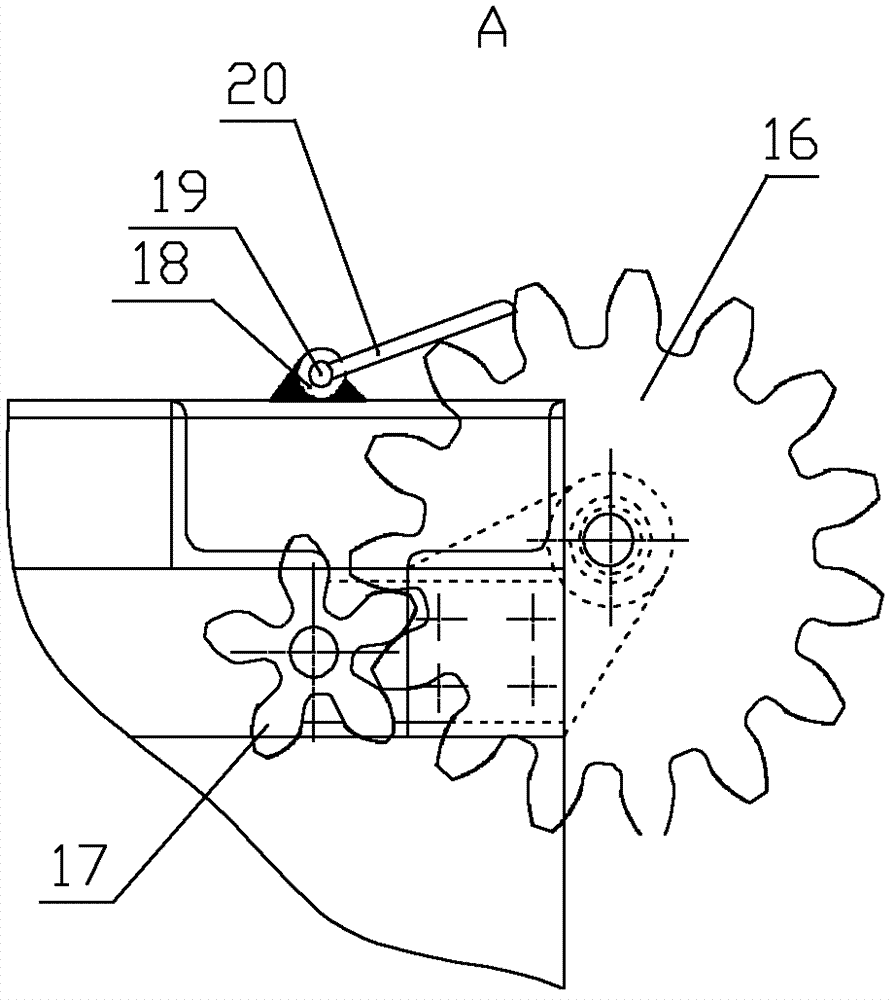

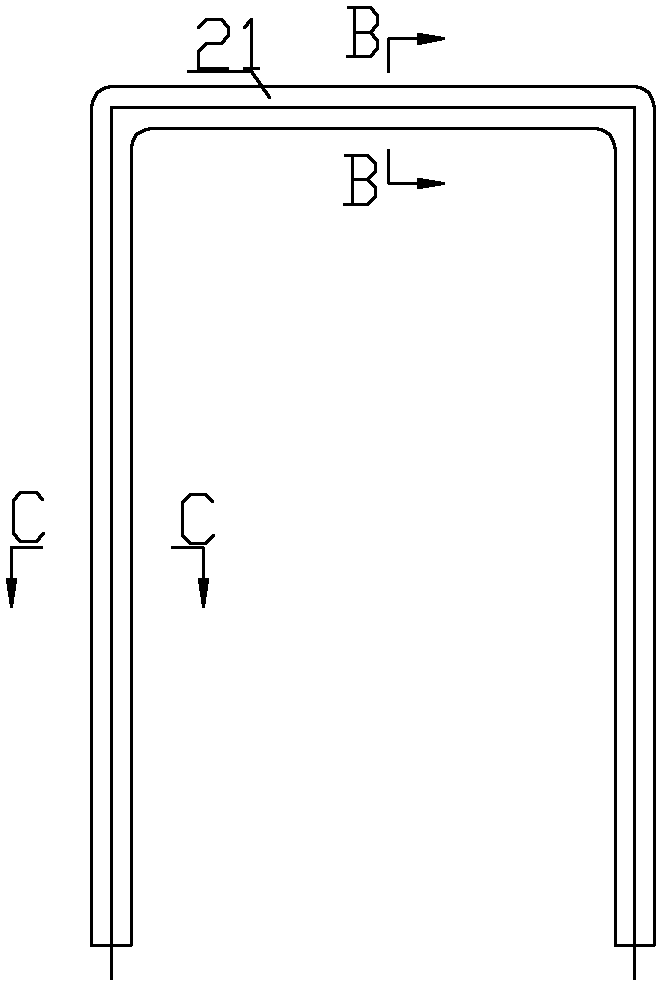

[0046] Figure 1 to Figure 8 It is the anti-shock rotary plate feeder described in Embodiment 1, which includes a material guide trough 1 and a rotating plate device 11, wherein the material guide trough 1 includes a material guide trough side plate 10 and a gate mechanism 4, and the material guide trough 1 is directly connected to the silo port 2, and the gate mechanism is set at the feed end of the material guide trough 1. The gate mechanism includes a gate, and the gate can be an obliquely inserted gate as shown in the figure, and the gate adopts a hydraulic cylinder mechanism. A rolling rake 8 is provided in the guide trough 1, and the rolling rake 8 includes a rake shaft and / or a rake cylinder, such as Figure 7 and Figure 8 As shown, the rake tooth 23 and the rake tooth holder 24 are detachably connected, and the shaft of the rake tooth 23 is inserted into the fixing hole of the rake tooth holder 24 for positioning. The surface of the rake shaft and / or the rake cylind...

Embodiment 2

[0053] Figure 9 It is the anti-shock rotary plate feeder described in Embodiment 2. The difference from Embodiment 1 is that: at the bottom of the feed trough 1, the joint and contact of the rotary plate and the feed trough are provided with a water-leakage coal chute 22 as shown in the figure, and the water-leakage coal chute 22 is inclined from It is arranged in a slippery shape, and it collects materials such as water and coal leaked from the gap between the hinge shaft 14 and the side plate 10 of the material guide trough 1 .

[0054] Others are with embodiment 1.

Embodiment 3

[0056] Figure 10 It is the anti-impact rotary plate feeder described in Embodiment 3. The difference from Example 1 is that the rake shaft and / or the rake cylinder are arranged on the side plate of the material guide trough 1, and two chutes 9 are arranged symmetrically on both sides of the material guide trough, and the rake shaft and / or the rake of the rolling rake Or the rake cylinder is arranged in the chute 9, and the chute 9 is an arc-shaped chute, and the rake shaft and / or the rake cylinder can be fixed in the chute 9, and can also slide along the chute 9.

[0057] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com