Electromagnetic coil

A technology of electromagnetic coil and lead wire, applied in the direction of electromagnet, valve details, engine components, etc., can solve the problem of no variable resistance device, no variable resistance device electromagnetic coil, etc., to achieve reliable sealing, simple placement, reliable The effect of sealing and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

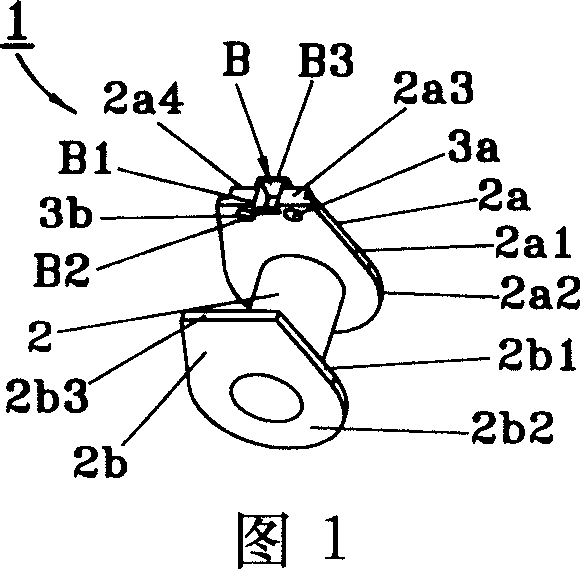

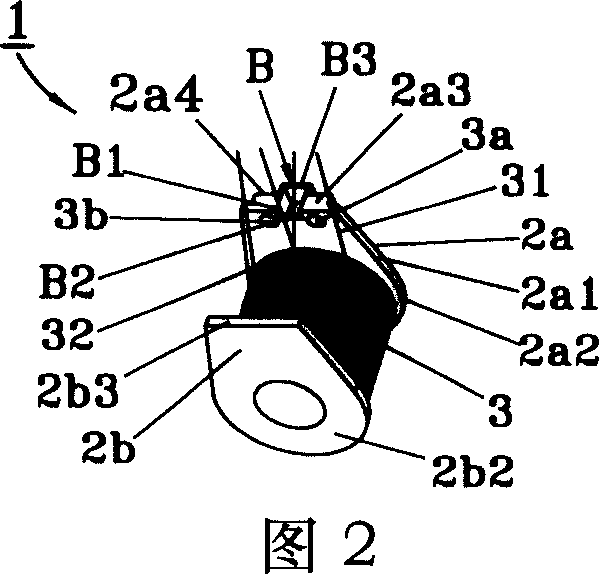

[0027] Fig. 1 is a perspective view of a bobbin 1 of an electromagnetic coil, which includes a hollow circular cylindrical winding core 2 and a pair of parallel flange-shaped parts 2a and 2b fixed at both ends of the winding core 2; the winding core 1 The collar-like parts 2a, 2b are integrally formed by synthetic resin, such as injection molding, and the resin material is polybutylene terephthalate, unsaturated polyester resin, phenolic resin and the like.

[0028] The collar-shaped parts 2a, 2b include arc-shaped parts 2a2, 2b2 and protruding parts 2a1, 2b1 formed by extending from the arc-shaped parts to one side.

[0029] The protruding portions 2a1, 2b1 have end surfaces 2a3, 2b3, respectively, and a wide portion 2a4 is formed in the center of one end surface portion 2a3, and a bucket-shaped depression B is formed in the wide portion 2a4.

[0030] The bucket-shaped depression B has an opening B1 of the end surface 2a3, a cut-in step B2 is formed inside the collar 2a, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com