Main current carrying contact system

A contact system and current-carrying technology, used in transformers, electrical components, variable inductors, etc., can solve the problem that the tap changer cannot be applied, and achieve the effect of simple structure, reasonable spacing and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention utilizes a simple structure, which can match the program requirements of the on-load tap changer and operate in a relatively large range. During the operation, under the premise of satisfying the preset overtravel, the angle of disengagement and closing is relatively small. The opening distance in the middle process of disengaging and closing is reasonable, and at the same time, the locking circle structure effectively guarantees the reliable operation of the mechanism.

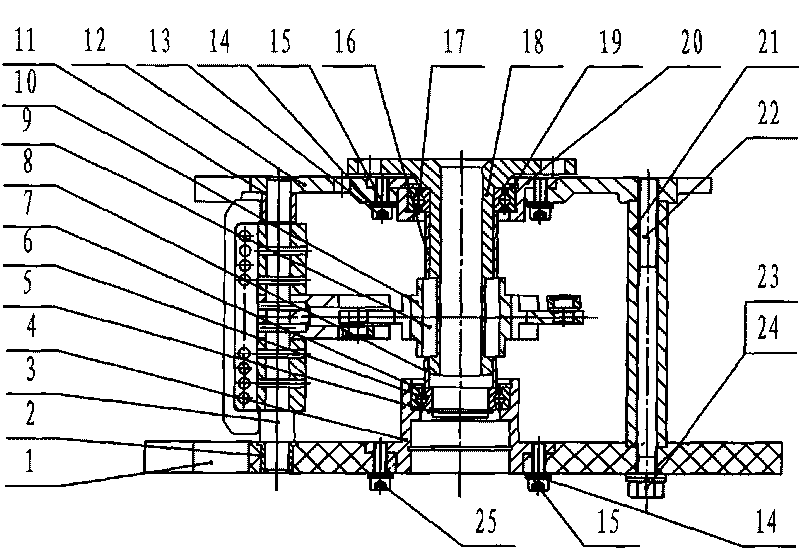

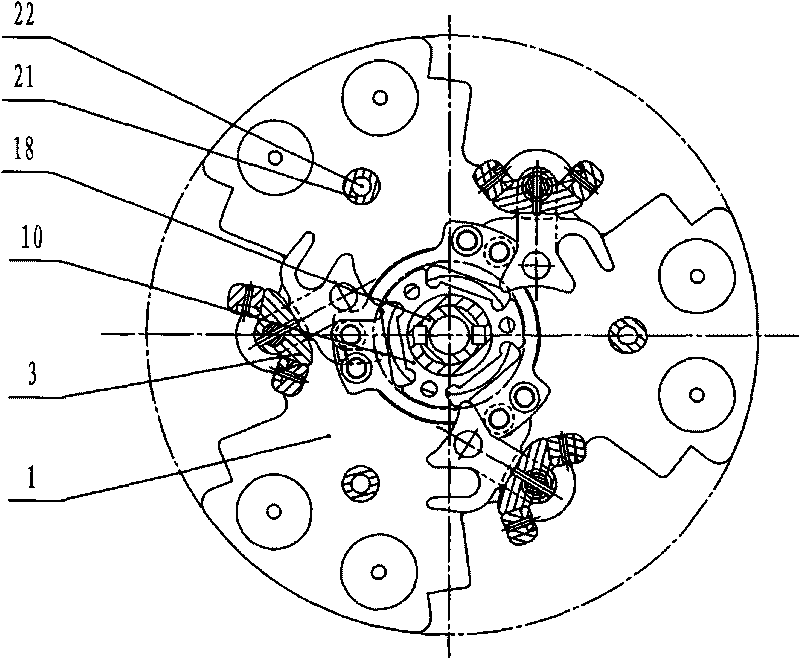

[0036] figure 1 and figure 2 It is a front view and a cross-sectional view of the main current-carrying contact system of the present invention. As shown in the figure, the main current-carrying contact system of the present invention includes: an upper mounting plate 12, a lower mounting plate 1, a first bearing bracket 4, and a second bearing bracket 20. The first bearing 6 , the second bearing 17 , the rotating shaft 18 and the first liner 21 .

[0037] The lower mounting plate 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com