Floating plate supporting device

A technology of supporting device and floating plate, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems such as the bottom surface and friction of the sheet that are difficult to solve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

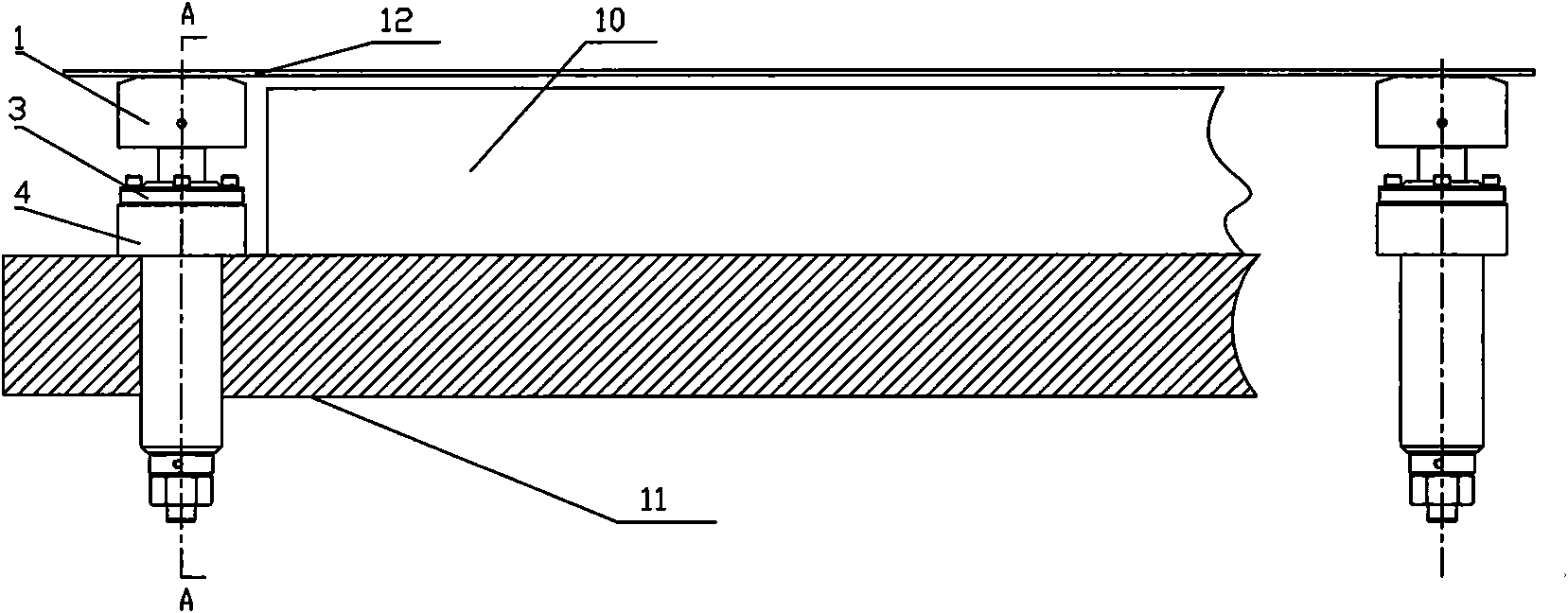

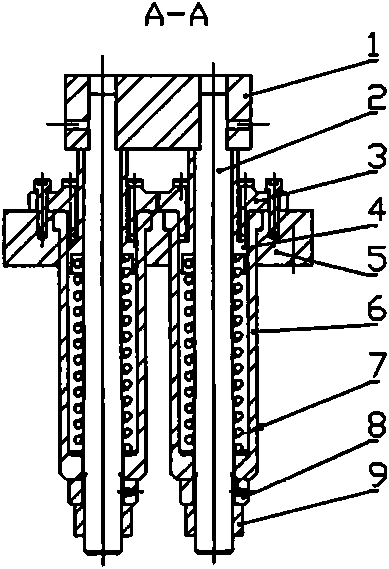

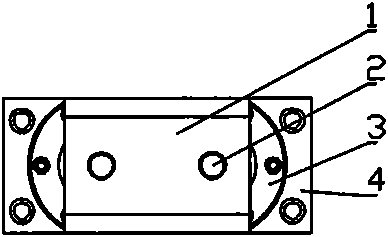

[0012] The present invention as figure 1 , 2 , 3 and 4, including the support block 1, the mounting seat 5 and the elastic support mechanism of the support block 1, the mounting seat 5 is fixedly connected to the side of the lower mold 10 on the workbench 11 of the fuselage, and the support block 1 is elastically The supporting mechanism is connected with the mounting seat 5, and the top surface of the supporting block 1 is slightly higher than the height of the top surface of the lower mold 10. The elastic support mechanism includes stud 2, spring 7, cover 3, guide sleeve 4, guide cylinder 6, stop nut 8, parallel nut 9; stud 2, spring 7, cover 3, guide sleeve 4, guide cylinder 6 are coaxially sleeved, the guide cylinder 6 is fixedly connected with the mounting seat 5 through the guide sleeve 4, the lower end of the stud 2 protrudes from the guide cylinder 6, and the protruding part is connected with the stop nut 8 and the parallel nut 9 in order to realize the adjustment fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com