Platform system for transformer installation

A transformer and platform technology, applied in the field of transformers, can solve problems such as power outages, affecting the living needs of surrounding residents, and the inability to maintain a safe distance between high-voltage and low-voltage wiring harnesses, and achieve the effects of convenient construction, avoiding falling from high altitudes, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

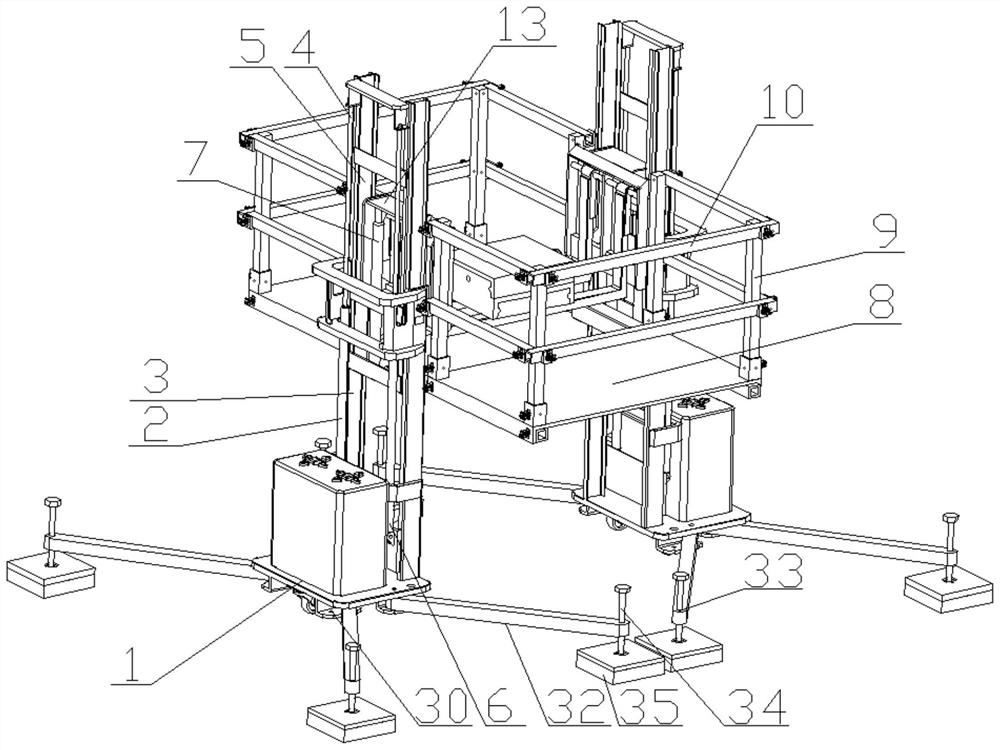

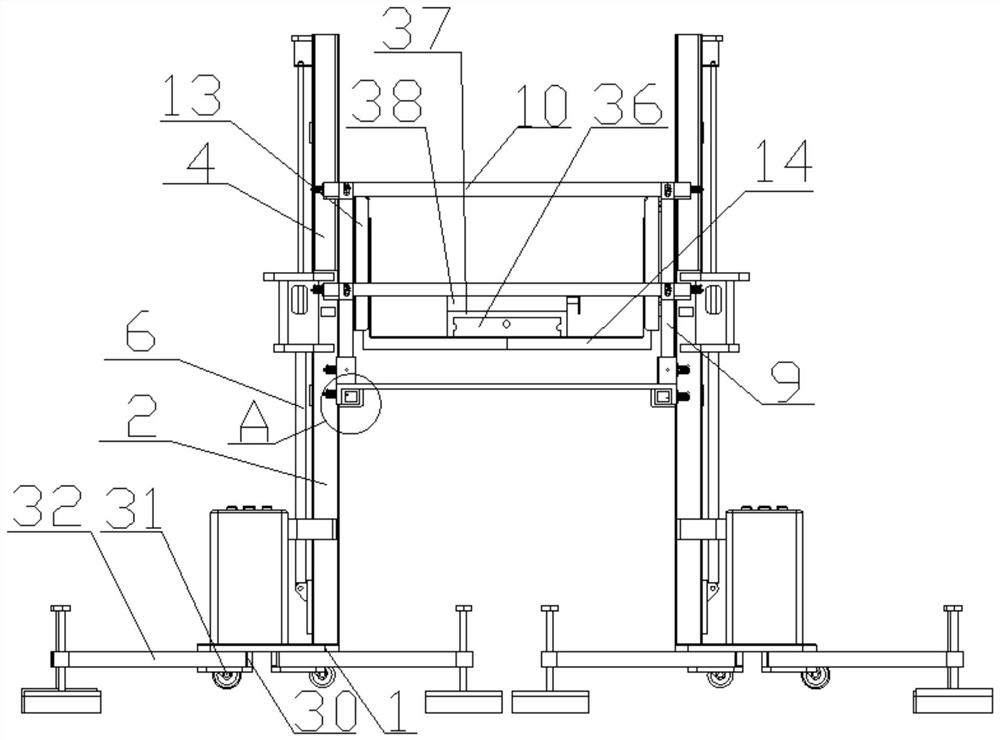

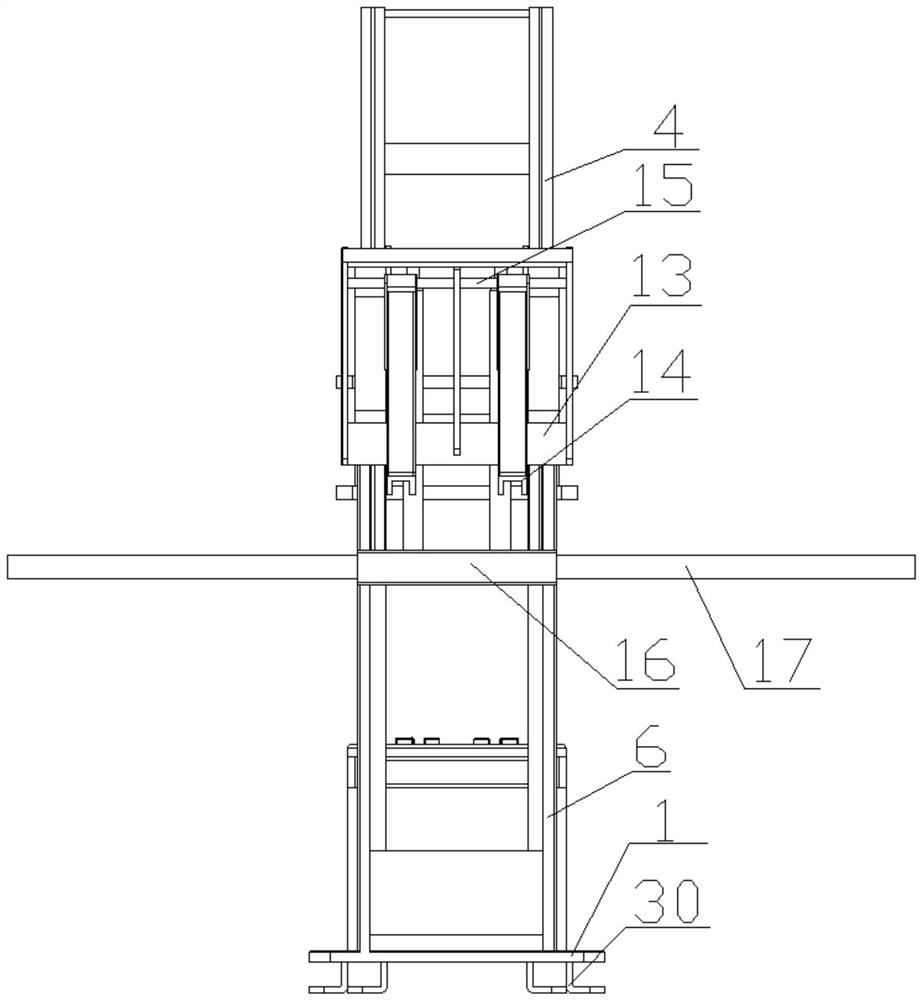

[0037]Such asFigure 1-10As shown, the platform system for the transformer is mounted, including the first lifting device, the second lifting device, the construction platform portion, wherein the first lifting device and the second lifting device are symmetrical, the first lifting device and the The second lifting device includes a base 1, a support post 2 disposed on the base 1, and the support post 2 has two, and the two of the support post 2 is concave in the side wall of the support column 2, the first slide groove 3, A rectangular frame 4 is provided in the first slide 3, the rectangular frame 4 and the opposite surface of the two edges parallel to the support post 2, and a transformer is provided in the second chute 5. The first hydraulic telescopic cylinder 6 is provided between the support column 2 and the rectangular frame 4, the first hydraulic telescopic cylinder 6 telescoping the rectangular frame 4 to move along the first slide 3, A second hydraulic telescopic cylinder ...

Embodiment 2

[0039]Such asFigure 1-10As shown, the present embodiment is substantially identical to the first embodiment, and the difference is therefore, further comprising a fastening device, both sides of the bottom plate 8 are provided with a flange 18, the fastening device to pass the flange 18 The bottom plate 8 is relatively opposite to the crossbar 17, and the mounting seat 12 is in-shaped structure, and one end of the mounting seat 12 is fixed to the column 9, and the mounting seat 12 is provided with a fastening device. The fastening device can secure the column 9 to the outer rod 10, and the sidewall of the jack 11 is provided with a fastening device, and the fastening means can secure the bottom plate 8 to the column 9. The fastening device includes a fixing plate 19, a U-shaped block 20, a plug, and a spring 21, and both ends of the U-shaped block 20 are connected to the fixing plate 19, and the U-shaped block 20 and the fixed plate 19 are arranged throughout Head, the latop is inse...

Embodiment 3

[0041]Such asFigure 1-10As shown, the present embodiment is substantially the same as that of Example 2, and the difference is that the bottom portion of the first lifting device and the second lifting device is provided with a tab 30 and a universal wheel assembly 31, and the mounting end 30 The support rod 32 is rotated, and the support rod 32 is provided with a second threaded hole 33 away from one end of the mounting tab 30, and the second threaded hole 33 is provided with a thread 34, the thread 34 away from the transformer. One end of the lifting portion is hinged by a ball 35. Also included with a two-dimensional platform, the two-dimensional platform is disposed at the top of the fork teeth 14 including a fixed stage 36, a first mobile station 37, a second mobile station 38, a first driving screw 39 The second driving rod 40, the bottom of the first mobile station 37 is provided with a first tab, the first connection, and a first threaded through hole, and both ends of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com