A shot blasting device for the production and processing of aluminum alloy castings

A technology of aluminum alloy castings and shot blasting devices, which is applied in the direction of used abrasive processing devices, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the efficiency of shot blasting machine processing and the inconvenience of installing or disassembling aluminum alloy castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

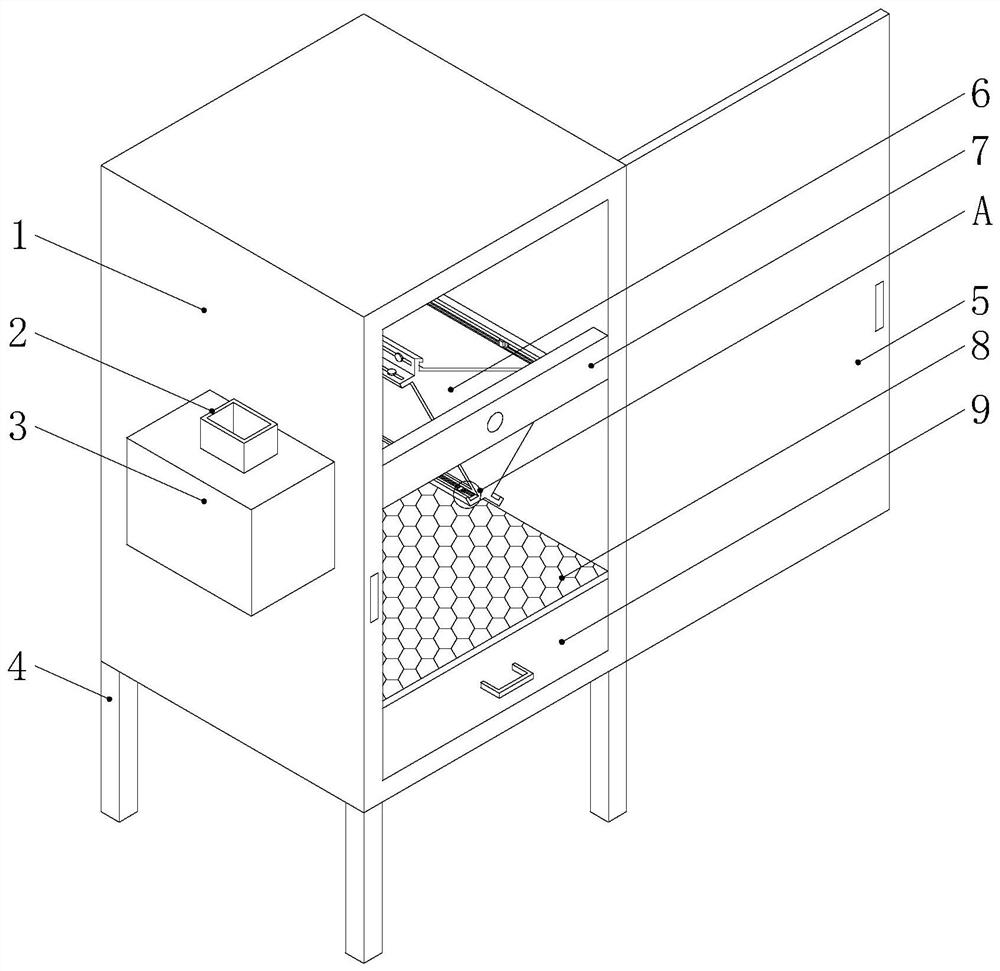

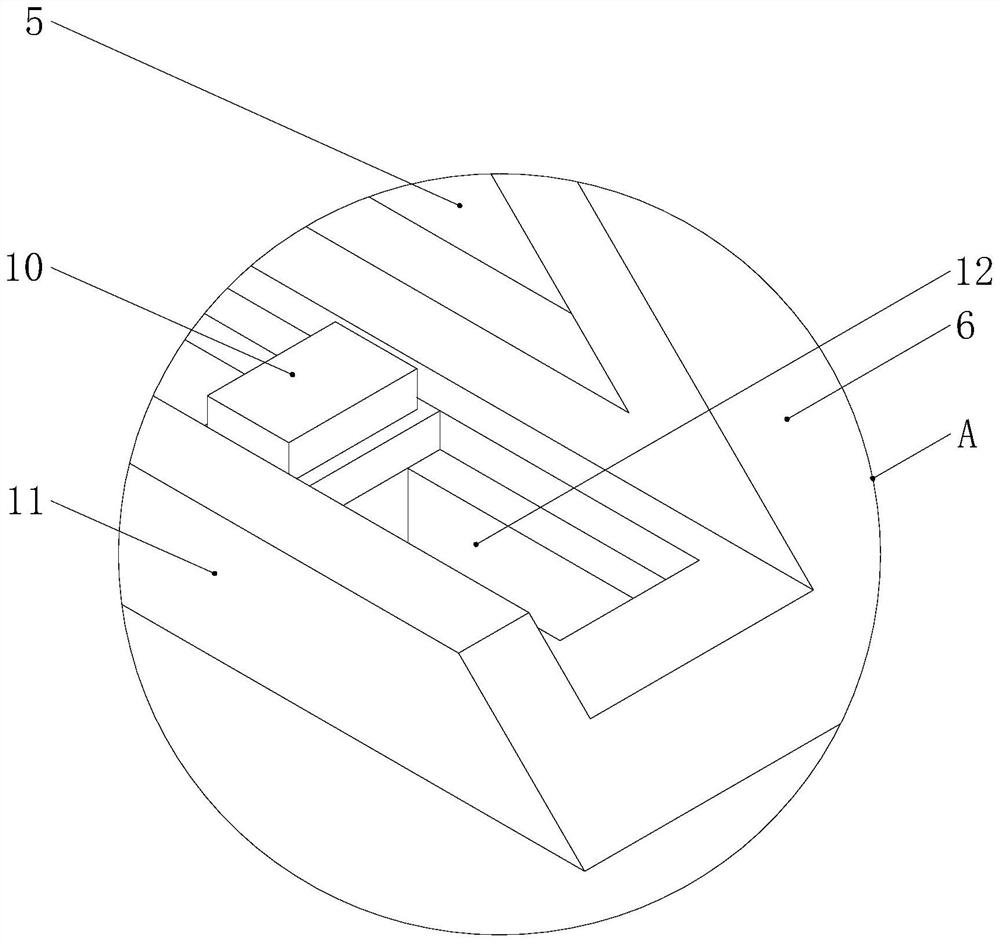

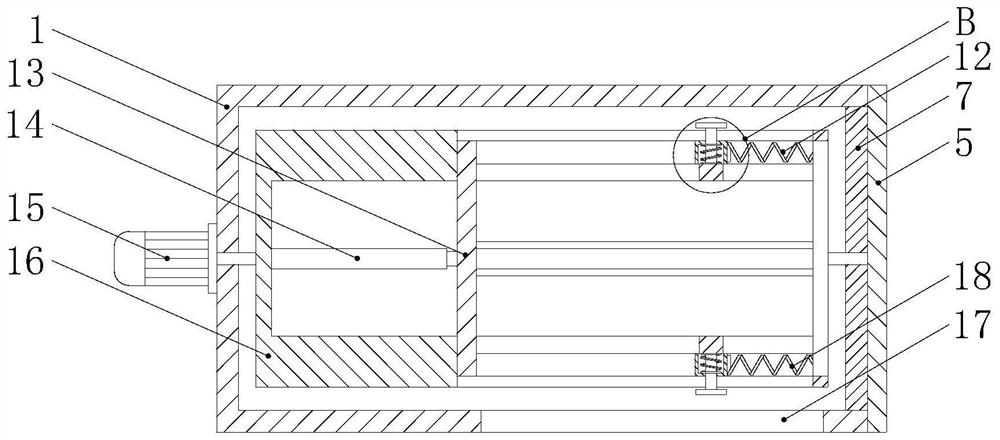

[0023] Example: such as Figure 1-4 As shown, a shot blasting device for the production and processing of aluminum alloy castings of the present invention includes a shot blasting machine main body 3 and a casing 1, the shot blasting machine main body 3 is preferably a QGWXI type shot blasting machine, and the shot blasting machine main body 3 passes through the first The switch is electrically connected to the external power supply. The main body 3 of the shot blasting machine is fixed in the middle of one side of the box body 1. The middle part of the top of the main body 3 of the shot blasting machine is fixed with a shot blasting bucket 2. The box body 1 and the main body of the shot blasting machine 3 There is a pill inlet 17 at the connection, and a motor 15 is fixedly installed on the back of the box body 1. The motor 15 is preferably a Y160M-2 type motor. The motor 15 is electrically connected to the external power supply through the second switch. Fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com