Passing-type shot blasting machine

A shot blasting machine and shot blasting room technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of easy dumping of H-beams, and achieve the effect of improving shot blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

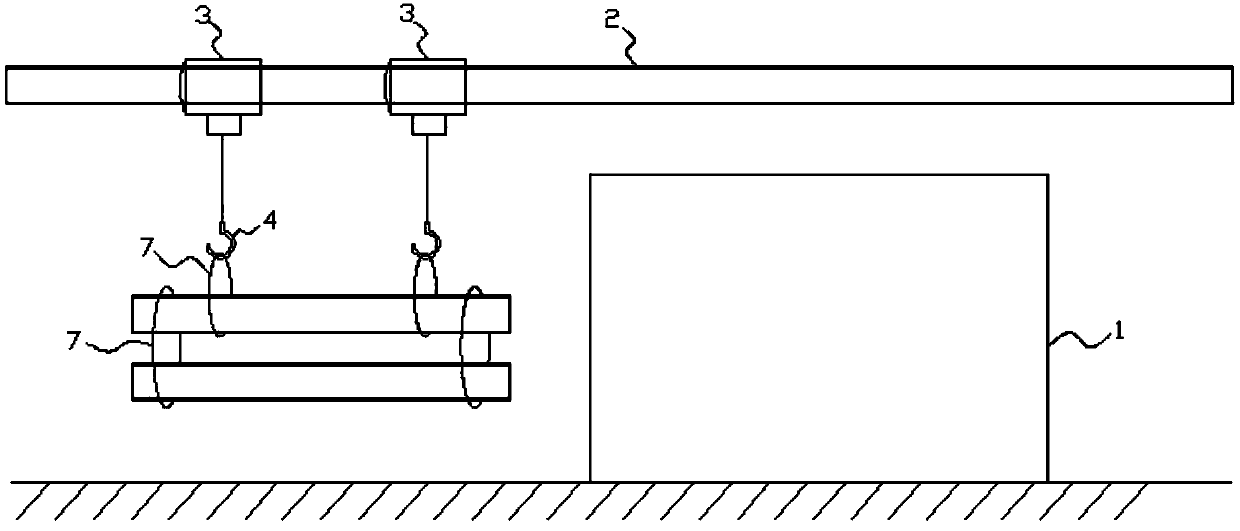

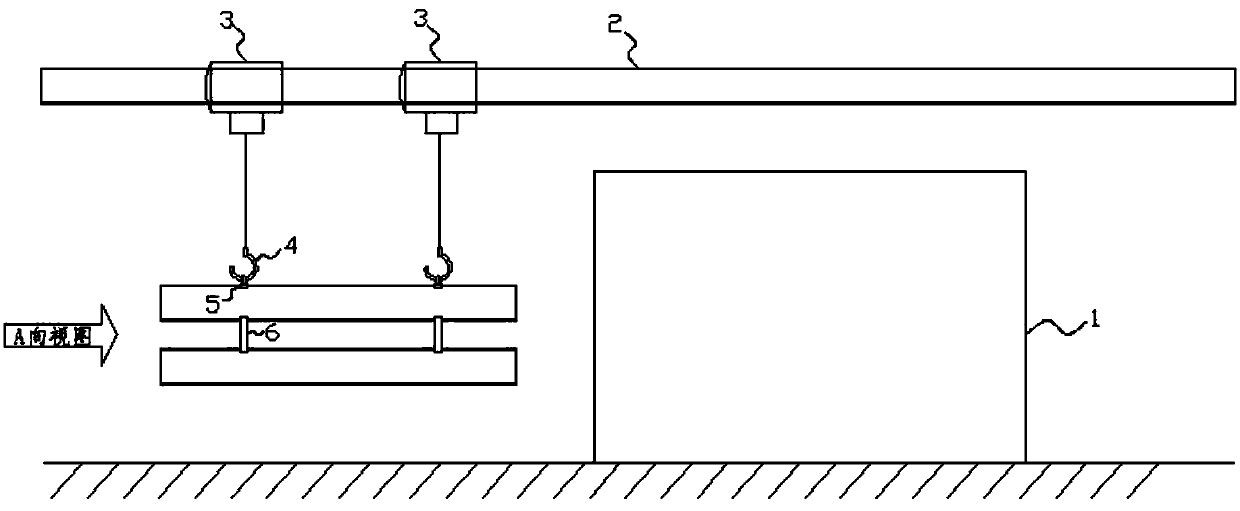

[0021] Such as figure 2 and image 3 As shown, the pass-through shot blasting machine of this embodiment includes a shot blasting chamber 1, a track 2, a walker 3, a hook 4, a first clamp 5 and a third clamp 6;

[0022] The track 2 is located above the shot blasting chamber 1, and two walkers 3 are installed on the track 2. The walker 3 is equipped with a motor and a roller inside, and the motor drives the roller to reciprocate along the track 2;

[0023] The hook 4 is installed on the walking device 3 through an iron chain;

[0024] The shot blasting chamber 1 is provided with a plurality of shot blasting devices, and each shot blasting device sprays shot material on the H-shaped steel passing through the shot blasting chamber 1 from different angles;

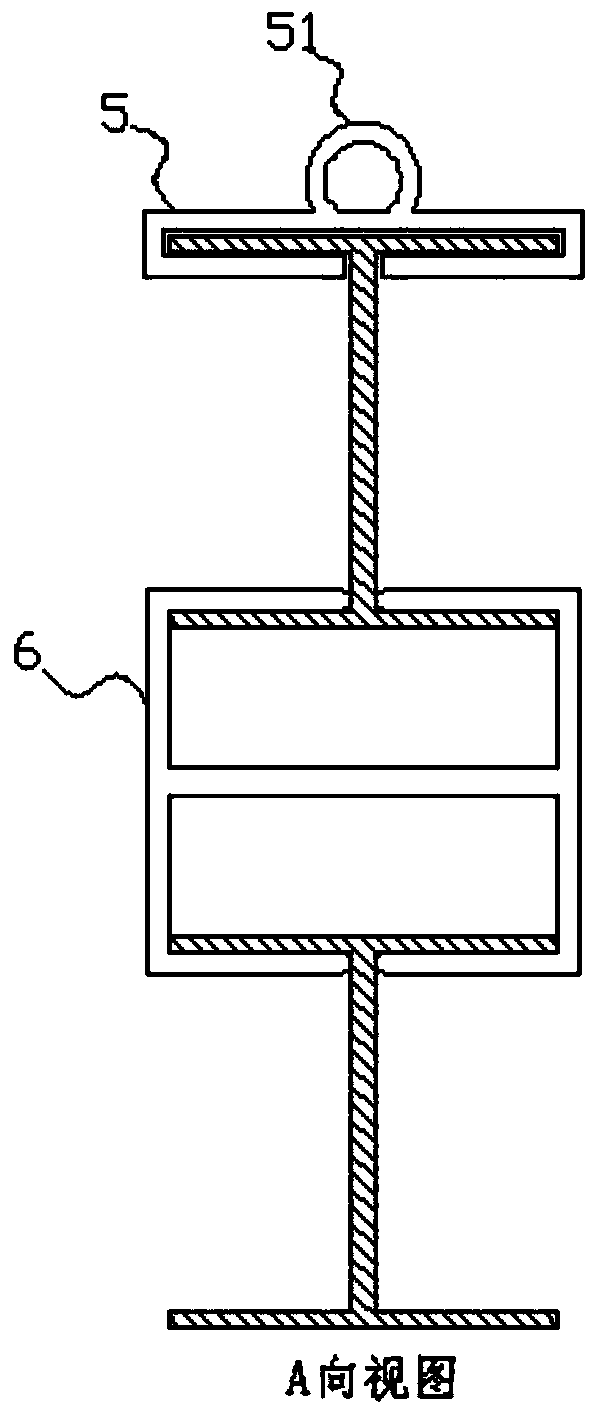

[0025] Such as image 3 As shown, the cross-section of the first clamp 5 is in the shape of a zigzag, and the inner cavity of the zigzag shape is larger than the cross-section of the upper wing plate of the H-shaped steel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com