Shot blasting treatment process

A treatment process and shot blasting machine technology, applied in the field of shot blasting process, can solve the problems affecting the roughness and service life of the workpiece, inconsistent shot blasting effect, etc., and achieve the effects of high cost performance, improved shot blasting quality, and improved shot blasting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

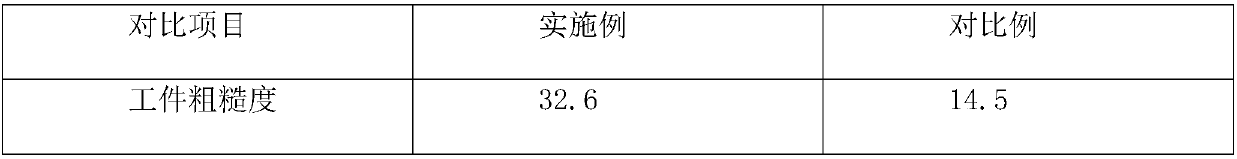

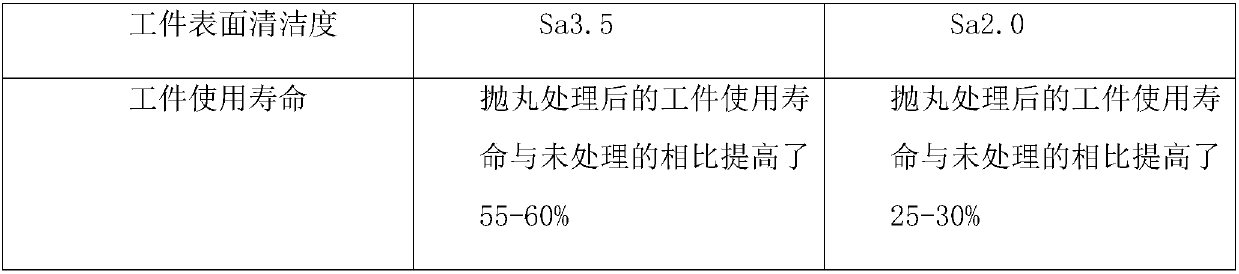

[0024] A shot blasting process provided in this embodiment includes the following steps:

[0025] S1: Measure the thickness of each part of the workpiece;

[0026] S2: Put the workpiece into the degreasing agent solution heated to 55°C for degreasing treatment, then put the workpiece into clean water, wash it with water, then take out the workpiece, blow off the water on the surface of the workpiece with compressed air, and then put it in the drying oven Carry out drying in the drying room until the moisture content of the workpiece is less than 0.3wt%;

[0027] S3: After the shot blasting equipment is debugged, place the dried workpiece in the shot blasting chamber, adjust the speed of the shot blaster according to the thickness of the workpiece facing the shot blaster, and perform shot blasting, and this part of the shot blasting is over Finally, turn the workpiece over, and turn the other part of the workpiece towards the nozzle of the shot blaster, so that the distance be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com