Turnover type shot blasting machine for coil wire

A flip-type, shot blasting machine technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., can solve the problems of good interlayer relationship damage, waste, and large wire rope spacing, etc., to achieve improved shot blasting efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

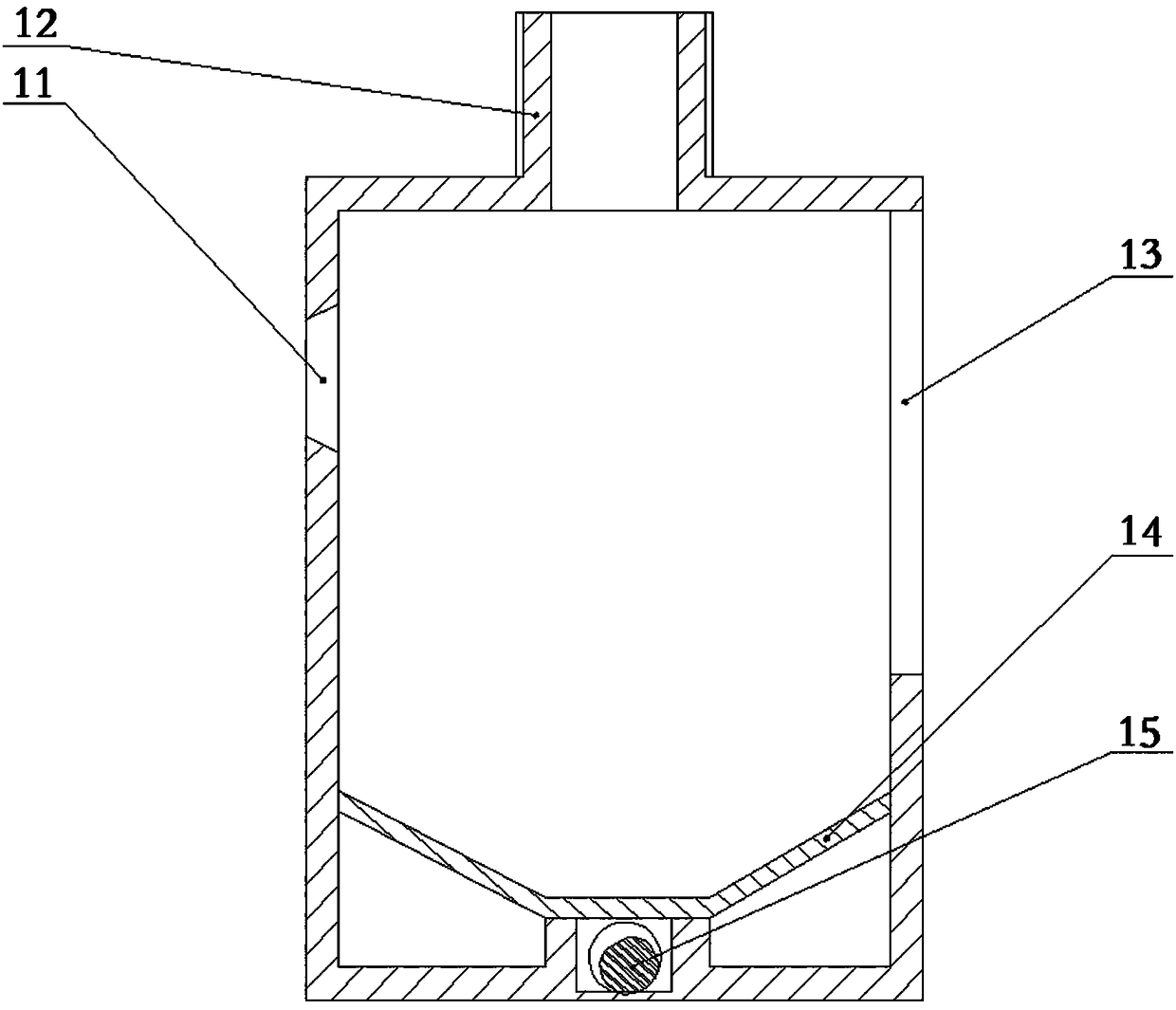

[0044] For the shot blasting machine, its inherent configuration must include the shot blasting chamber 1 and the shot blasting device 9. In some implementations, a shot recovery device can be selected, such as image 3 The floor drain plate 14 and the screw conveying device 15 are shown.

[0045] For different workpieces, in some applications, a feeding device needs to be provided, while in other applications, only workpiece tooling needs to be installed in the shot blasting chamber 1 .

[0046] For the coil wire, as described in the background technology section, there are relatively many feeding methods, but in the embodiment of the present invention, the hanging rod assembly 3 in the hopper assembly is used to hang the material in the shot blasting chamber 1 The position of the workpiece is determined, and the coiled wire is dispersed by throwing the coiled wire through the cam 34 .

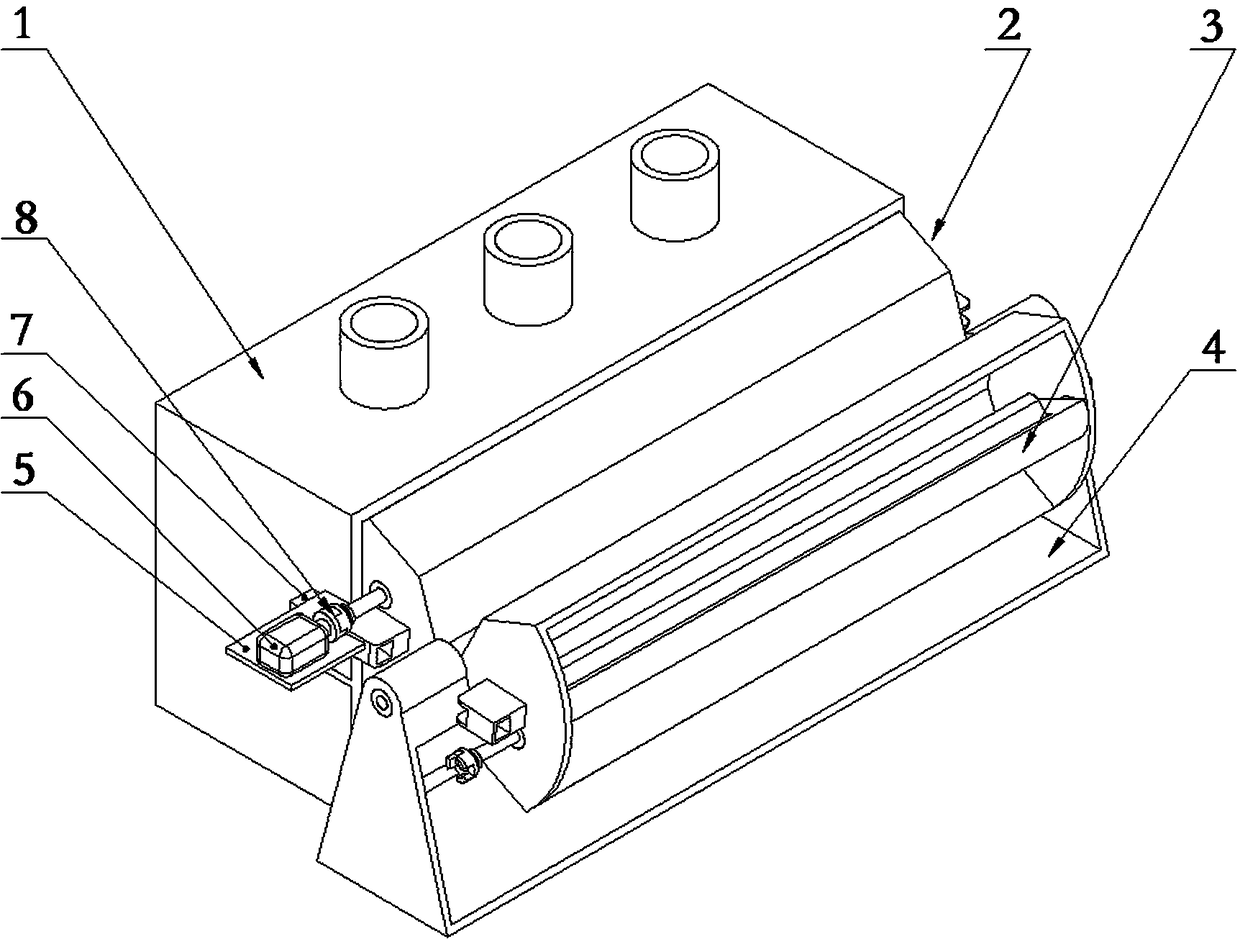

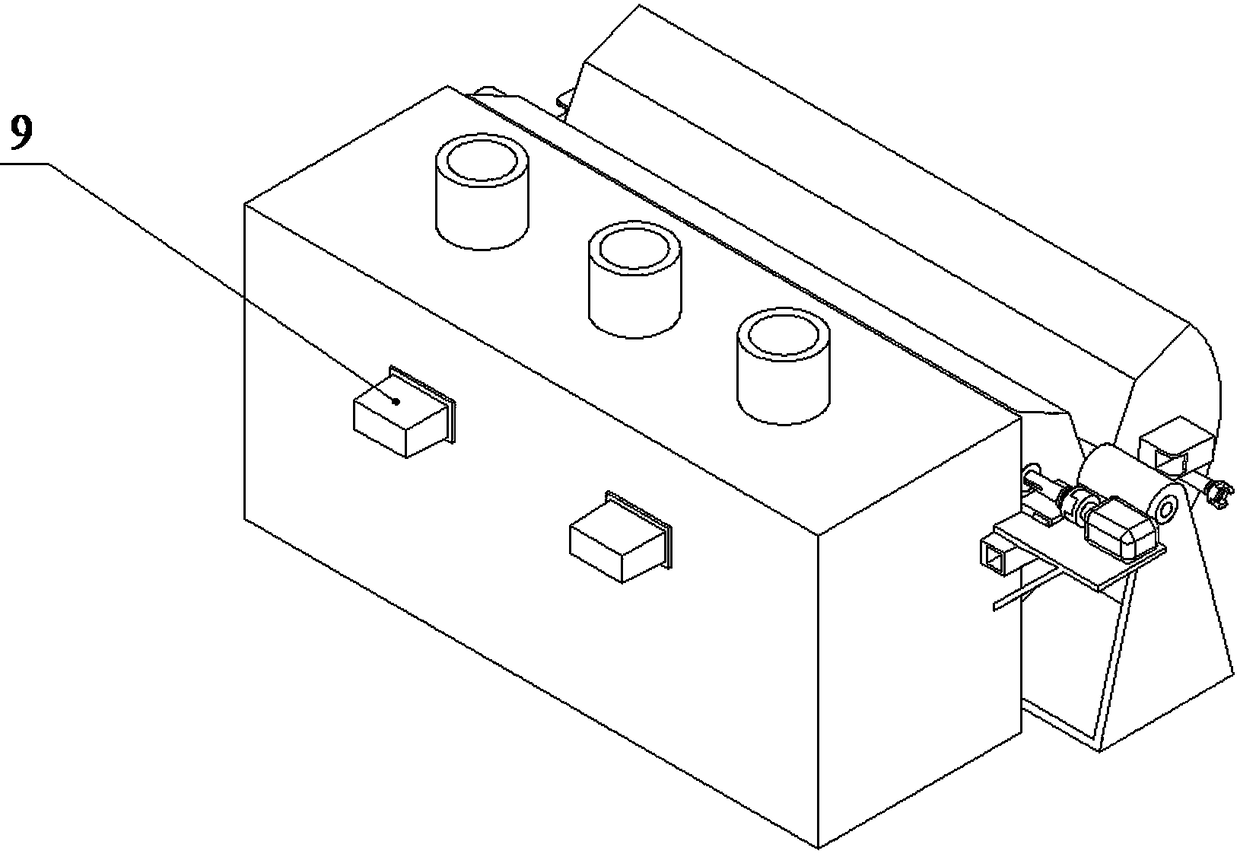

[0047] Further, see the attached figure 1 A kind of flipping coil wire rod shot blastin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com