Box body type workpiece shot blasting cleaning device for upper mobile material conveying

A shot blasting cleaning and top-mounted technology, which is applied in the direction of the used abrasive processing device, abrasive feeding device, abrasive, etc., can solve the problem that the relative direction of the projectile and the workpiece cannot be adjusted in all directions, and the treatment and cleaning are not complete. Realize automation and other issues to achieve the effect of low possibility of cleaning dead angle, efficient shot blasting treatment, and improved shot blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

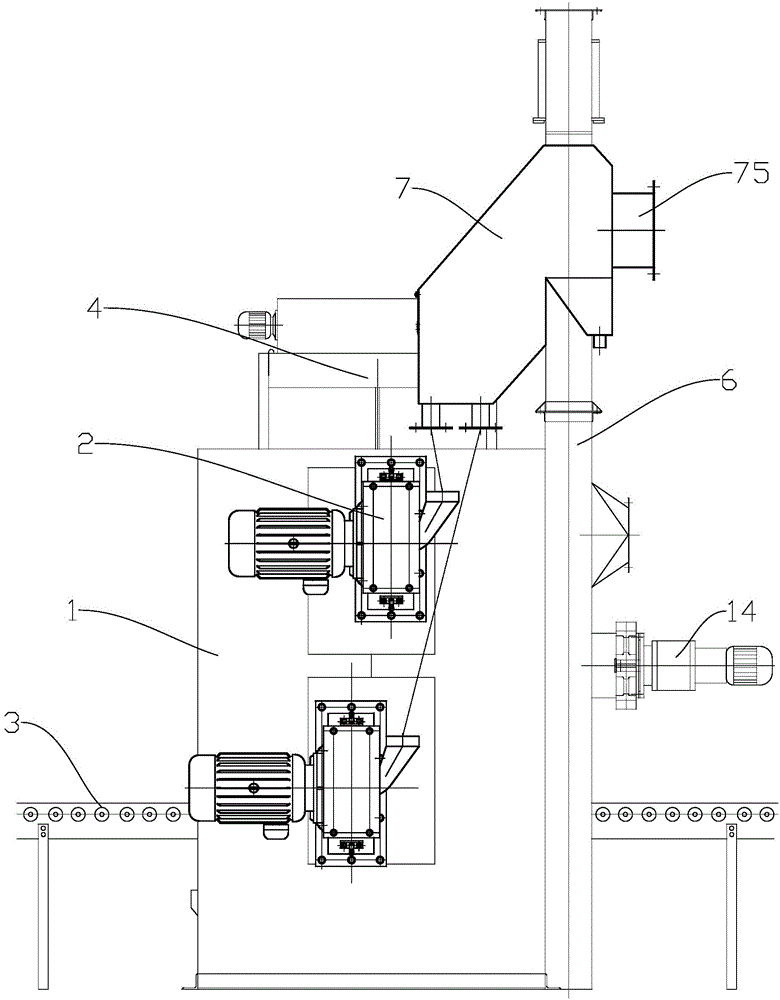

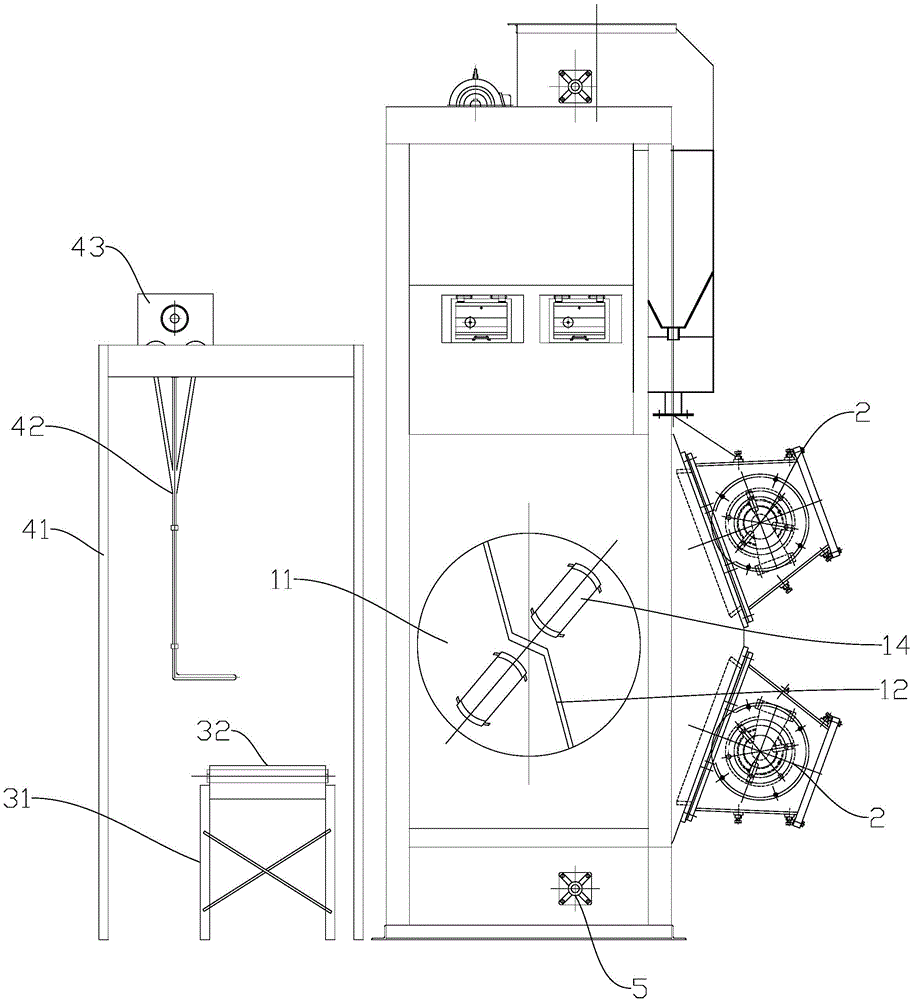

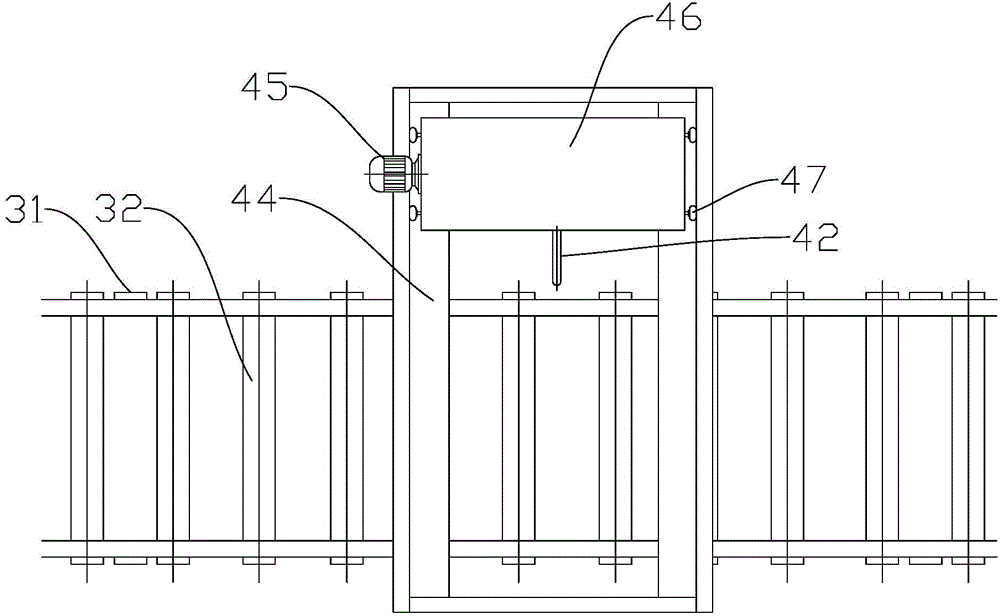

[0034] Such as Figure 1-7 As shown, the shot blasting device includes: a shot blasting chamber 1, a shot blasting device 2, a feeding roller table 3, a feeding manipulator 4, a shot sand circulation system and a shot sand separator 7.

[0035] One side of the shot blasting chamber 1 is provided with an observation port, and the side adjacent to the observation port is provided with a workpiece inlet. In the shot blasting chamber 1, there is a rotary table 11, which is a disc-shaped structure, and Perpendicular to the side where the viewing port is located. Rotary workbench 11 is driven by stepper motor, can realize intermittent rotation, and each rotation angle is 180 °. The rotary table 11 also includes two rotation systems, the two rotation systems are installed on the rotary table 11 along the diameter direction, separated by a part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com