Automatic turn-over and shot blasting machine for workpiece

A shot blasting machine and automatic turning technology, applied in conveyors, manufacturing tools, conveyor objects, etc., can solve the problems of low production efficiency, labor and time consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

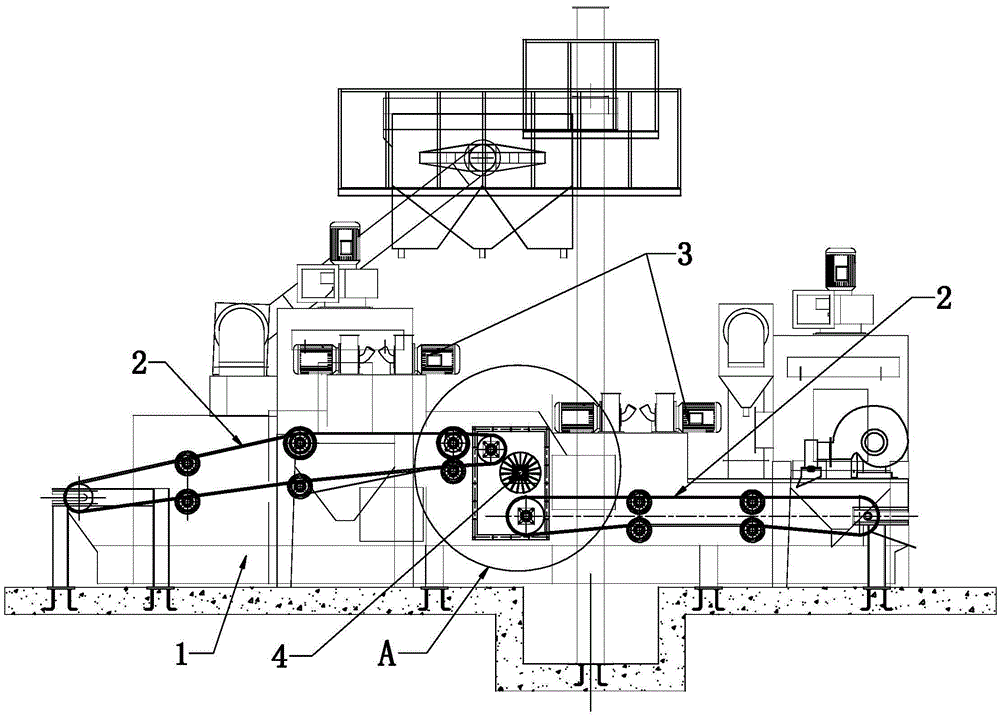

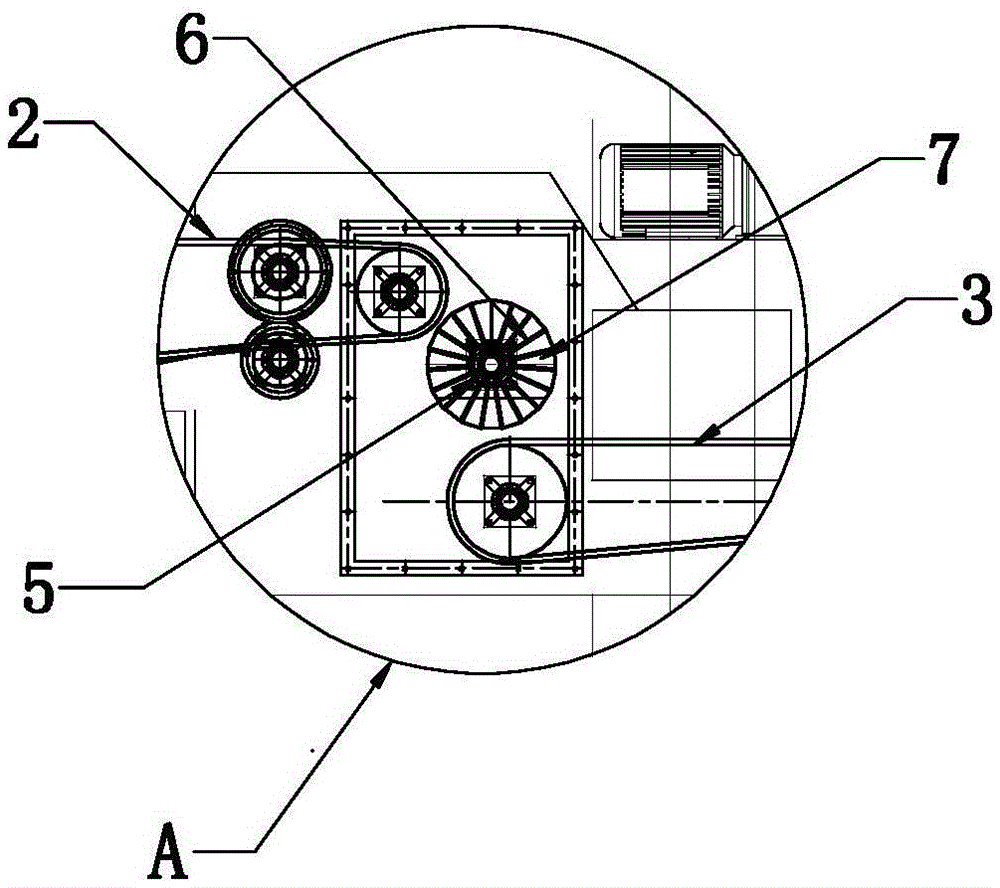

[0011] The workpiece automatic flip shot blasting machine of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] As shown in the figure, the workpiece automatic flip shot blasting cleaning machine of the present invention is mainly suitable for the shot blasting treatment of large quantities of workpiece pieces. It is a continuous circulation type in terms of structure, and the workpiece conveying form consists of two parallel crawlers ( Conveyor belt) is completed, it includes frame 1, the primary conveyor belt 2 at the front of the frame and the secondary conveyor belt 3 at the rear of the frame, the primary conveyor belt 2 and the secondary conveyor belt 3 are arranged parallel to each other and Running in the same direction, a pair of shot blasters for blasting workpieces on the primary conveyor belt 2 are arranged above the primary conveyor belt 2, and a pair of shot blasters for b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com