Double-layer detachable shot blasting machine roller way tool bracket

A detachable, shot blasting machine technology, applied in the field of steel structure manufacturing, can solve the problems of stuck in the round roller, downtime, and reduced production efficiency, and achieve the effects of preventing workpieces from falling, increasing the amount of feeding, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

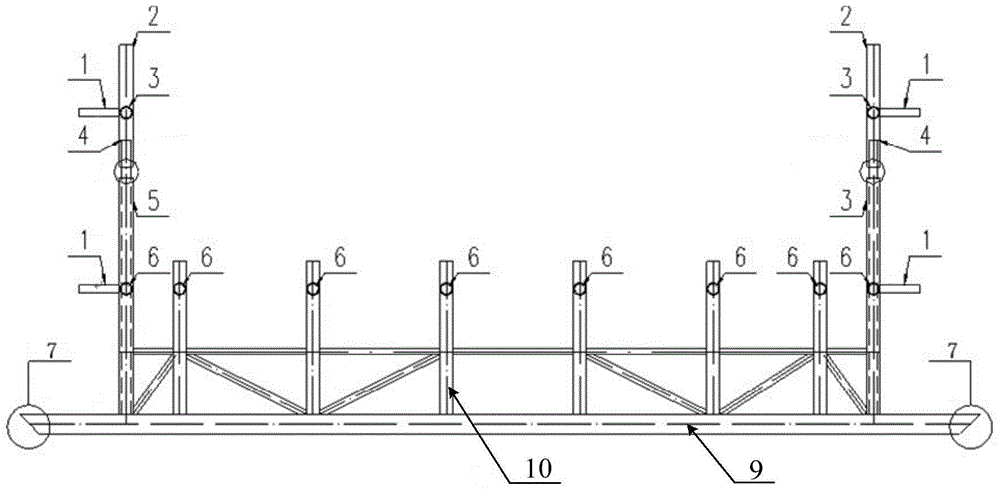

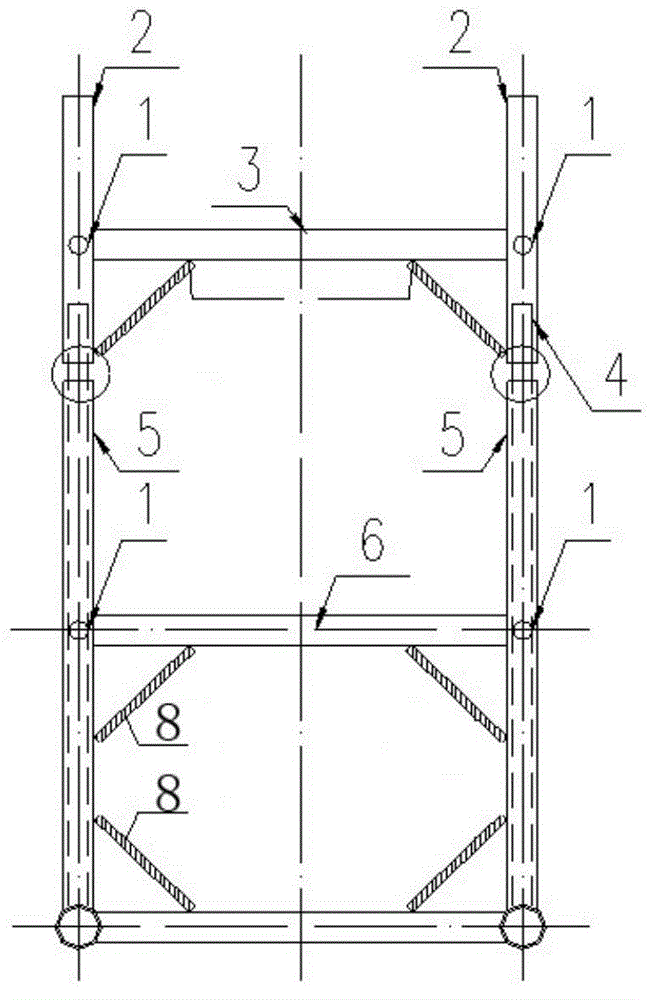

[0024] Such as figure 1 , figure 2 As shown, the embodiment of the present invention mainly improves the structure of the roller table tooling bracket of the shot blasting machine, which mainly includes handrails 1, a first-level horizontal bar 6, a first-level vertical bar 5, a second-level horizontal bar 3, and a second-level vertical bar 2 and roller table support 9.

[0025] Wherein, there are at least two roller table supports 9, and its two ends are installed on the roller table. Mouth 7; the quantity of one layer of vertical rod 5 is at least twice of the quantity of roller table support 9, and the lower ends of two layers of vertical rod 5 are respectively vertically installed on the same roller table support 9 both sides ends (here the end is not the top , refers to the position near the top), and the one-layer vertical rods 5 installed on the same side end of each roller table bracket 9 are parallel to each other and perpendicular to the plane where each roller ta...

Embodiment 2

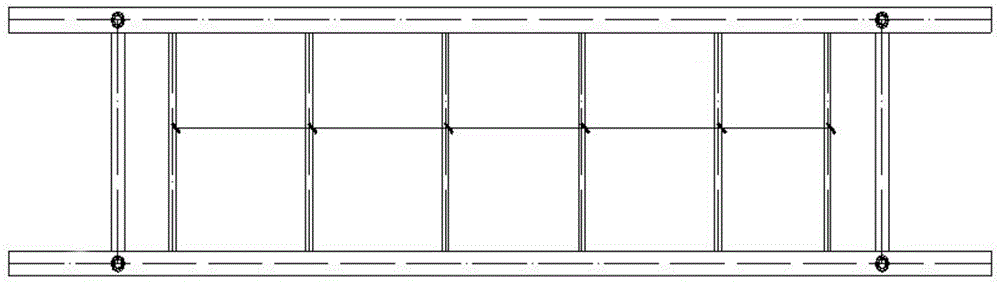

[0030] Such as figure 1 , image 3 As shown, the present embodiment carries out the following extensions on the basis of Embodiment 1, between two layers of vertical rods 5 at both ends of the same roller table bracket 9, along the roller table bracket 9, and one layer of vertical rods are sequentially fixed. Bar 5 is parallel to the mounting bar 10, and between the mounting bars 10 fixed on different roller table supports 9, the same cross bar as the height of one layer of cross bar 6 is installed, as preferably, the mounting bars on different roller table supports 9 10 are arranged at the same interval, and the cross bars fixed between the installation bars 10 are arranged to be parallel to the cross bars 6 of one floor. That is, improve the density of one deck of cross bars 6, except the one deck of cross bars 6 installed between one deck of upright bars 5, install a plurality of installation bars 10 for adding one deck of cross bars 6 (cross bars).

[0031] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com