Spiral material taking device

A reclaimer and screw technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of adding reclaimers, ordinary reclaimers can not normally reclaim materials, and increasing the weight of the front end of reclaimers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

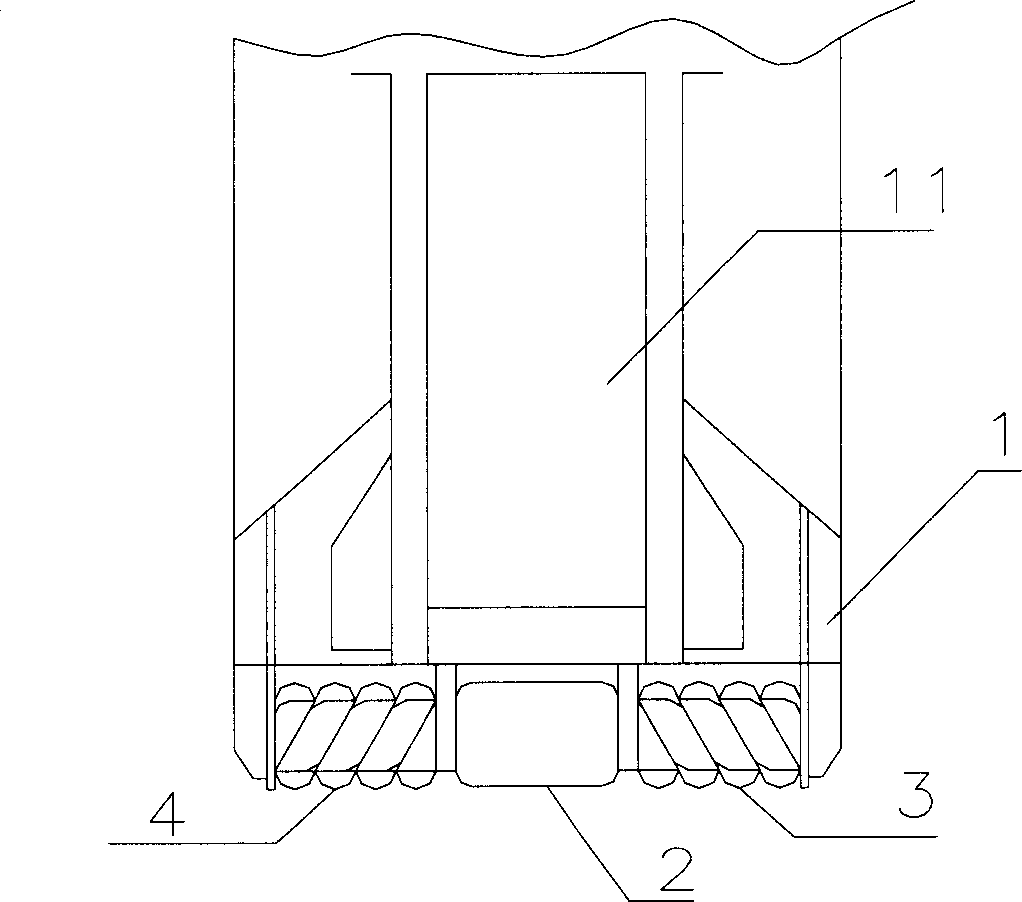

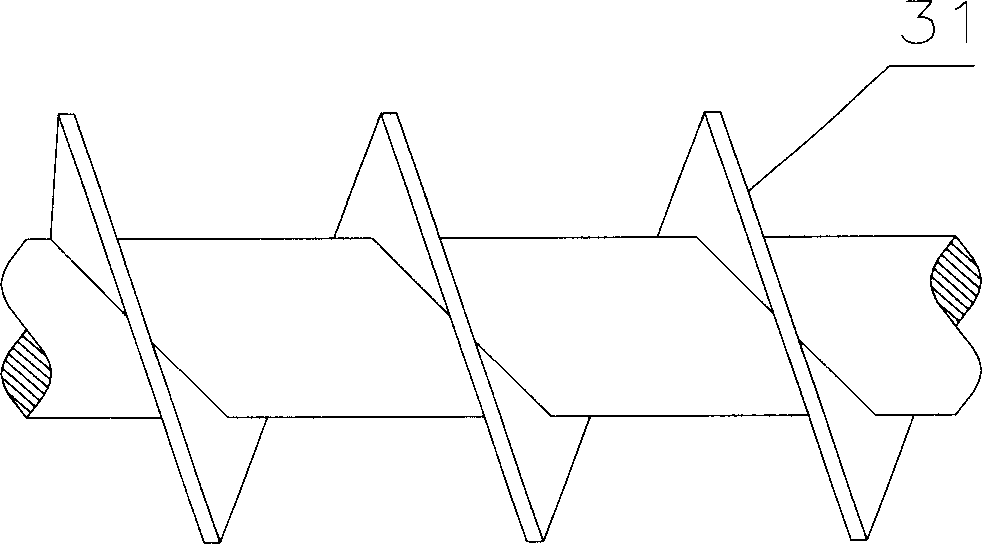

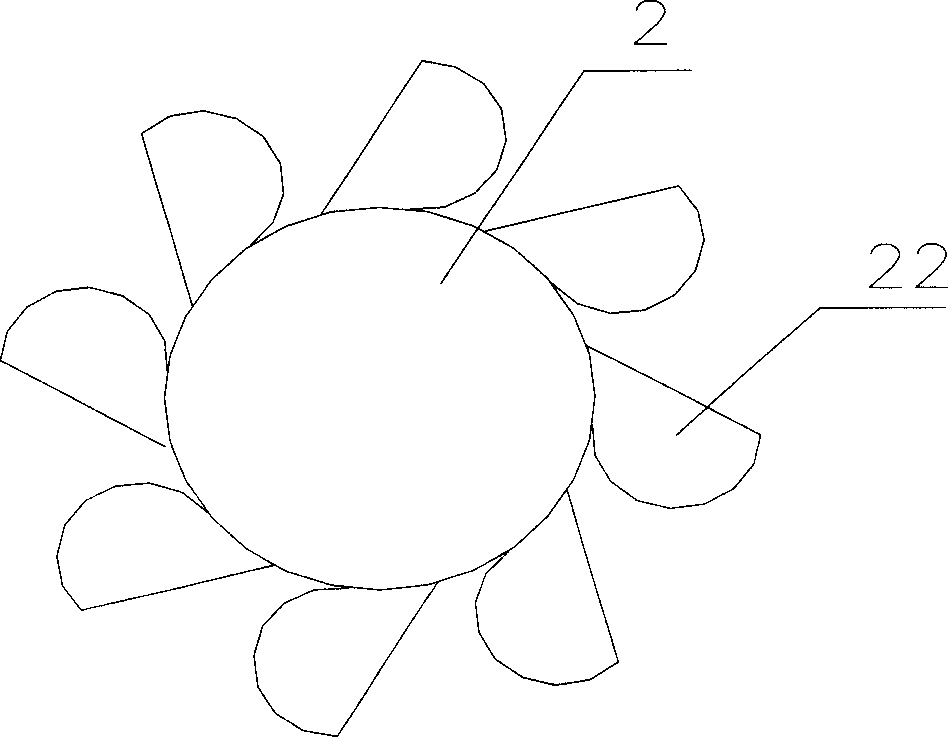

[0010] Such as figure 1 , 2 , 3, the present invention includes a bucket wheel 2 with a throwing bucket 22 arranged on the front end 1 of the reclaimer, and the two sides of the bucket wheel 2 are respectively provided with a left helical blade group 4 and a right helical blade group 3 . The bucket wheel 2 is located on the same central line as the left helical blade group 4 and the right helical blade group 3 . The outer diameters of the blades 31 of the left and right helical blade groups are equal, and the inner diameter of the throwing bucket 2 is slightly smaller than the outer diameter of the blades 31 of the helical blade groups.

[0011] When taking materials, the bucket wheel 2 rotates, drives the throwing bucket 22 to take materials, and throws bulk materials to the conveyor belt 11 . Due to the inertial effect of rotation, many bulk materials fall on the way in the throwing bucket 22. During this process, the left helical blade group 4 and the right helical blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com