Novel impeller head capable of improving input shot quality

A technology of shot blasting machine and high quality, which is applied in the direction of abrasive material feeding device, explosion generating device, abrasive material, etc. It can solve problems such as frequent failure, abrasive wear of shot material, and complicated maintenance, so as to prolong life, increase shot blasting amount, and Pill uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

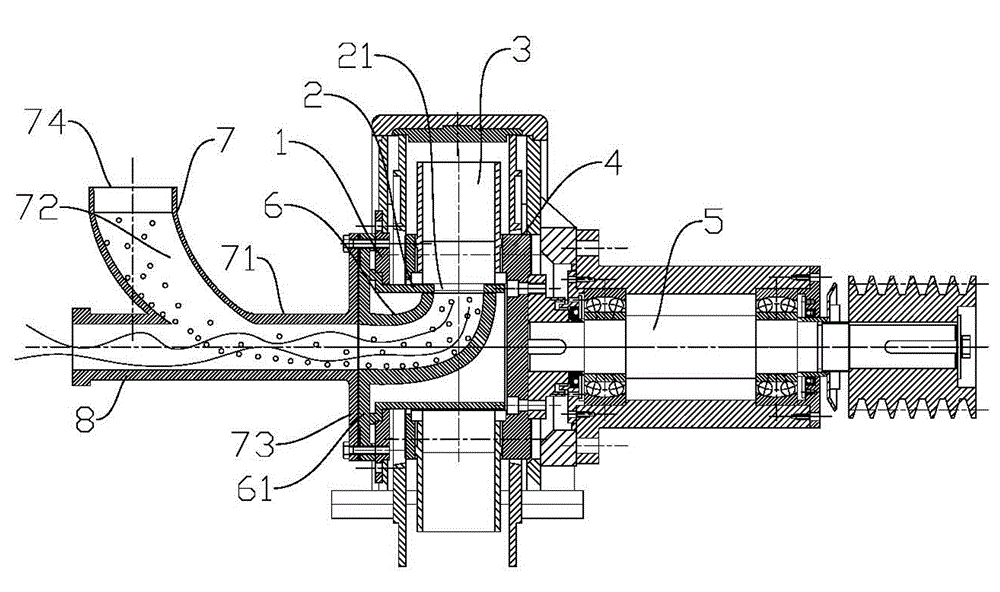

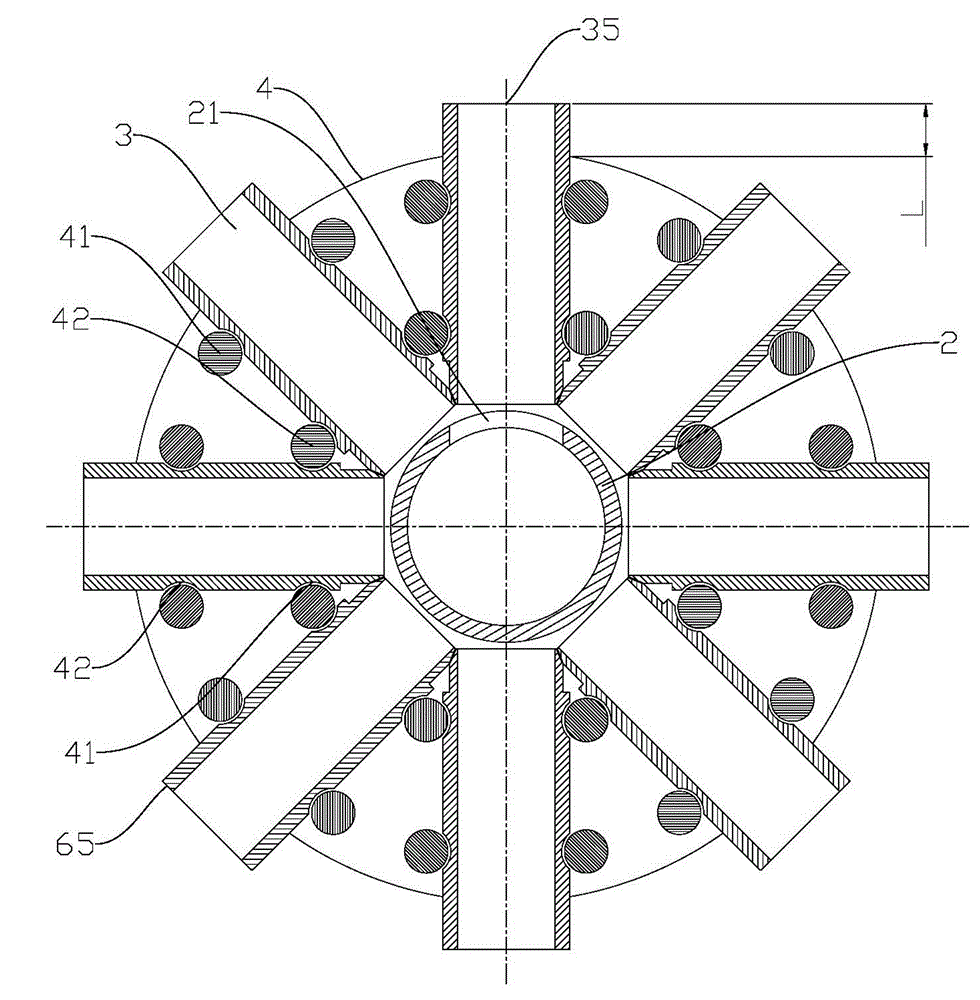

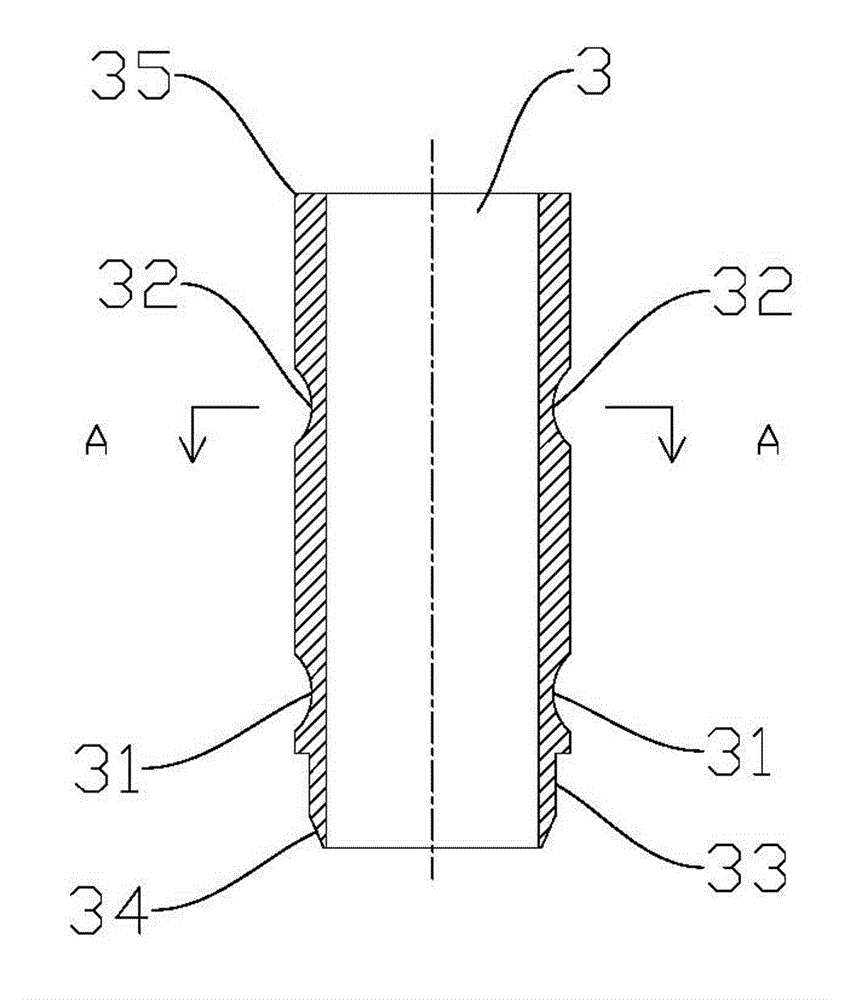

[0025] Such as figure 1 As shown, the new shot blasting machine that can improve the quality of shot delivery includes a shell 1, a shot tube, an orientation sleeve 2, a blade 3, an impeller body 4, and a main shaft 5; the blade 3 is installed on the impeller body 4, and the impeller body 4 Consists of two coaxial discs; the orientation sleeve 2 is provided with a shot blasting window 21; its special features are:

[0026] The pill inlet tube is composed of two parts: the inner pill tube 6 and the outer pill tube 7;

[0027] The pill inlet of the inner pill tube 6 is coaxial with the main shaft 5; and the first flange 61 is provided at the pill inlet end; The axis of the axis is vertical, and the shot blasting window 21 of the shot blasting window 21 of the directional sleeve 2 is docked with the shot blasting port of the inner shot tube 6; are the same.

[0028] The outer shot tube 7 includes a straight section 71 and a curved section 72; the shot outlet end of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com