Novel process for treating fermentation waste gas of amino acid by utilizing biofilter

A biological filter and amino acid technology are applied in the new process field of using biological filter to treat amino acid fermentation waste gas, which can solve the problems of high water temperature, high solid particles and large spray volume, so as to reduce the pressure of environmental protection and reduce the content of pollutants. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

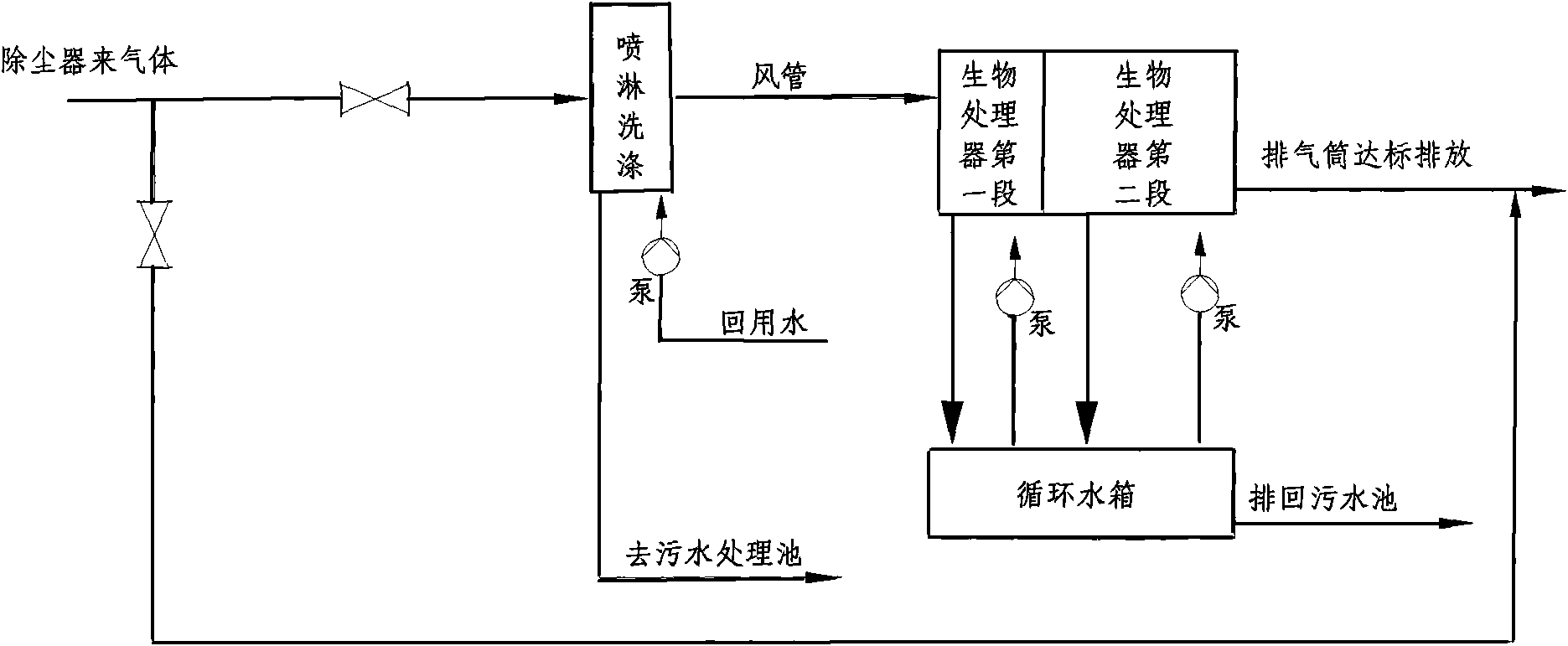

[0011] After the waste gas of the fermentation liquid is dedusted by Venturi and electrostatic dedusting, the flue gas and condensate containing extremely high COD are removed through the gas-liquid separator, and the condensate enters the sewage treatment system; when the flue gas is cooled to 35°C by spraying, it enters the biological filter The pool, under the action of microorganisms, decomposes the VOC in the flue gas, and the gas discharged up to the standard is sent out from the exhaust stack; the biological filter pool is composed of the first section of the biological processor and the second section of the biological processor, and the inside of the biological filter It is filled with a composite packing layer composed of quartz sand, ceramics and polypropylene, and the composite packing layer and microorganisms form a biological filter bed; in the first stage of the biological processor, that is, the pre-humidification zone of the biological pretreatment stage, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com