Design method and system for no air gap stable filling casting

A pouring system and stable mold filling technology, applied in casting molding equipment, molds, cores, etc., can solve the problems of easy scouring of molds, excessive metal flow rate, air entrainment, etc., to improve performance and service life, The effect of improving process yield and reducing design size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take the large-scale integral casting cast steel backup roll as an example, the material is 40Cr4, the weight of molten steel is 50t, the filling time is 7-8min, and the pouring temperature is 1550°C.

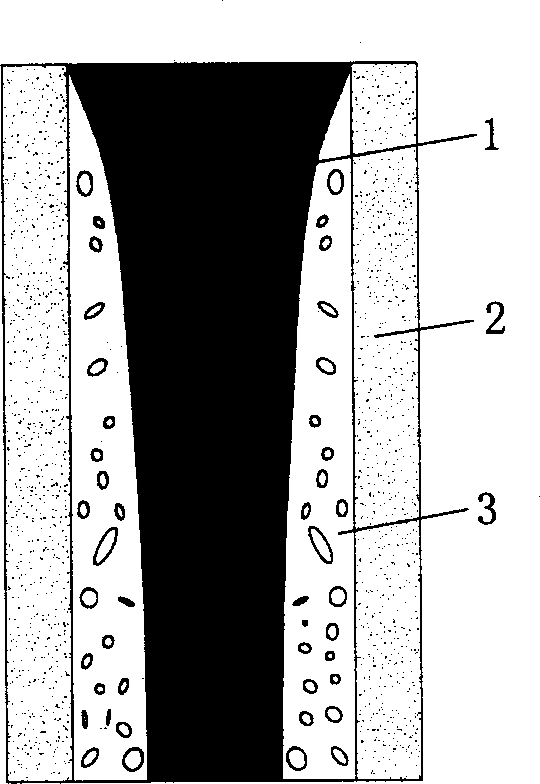

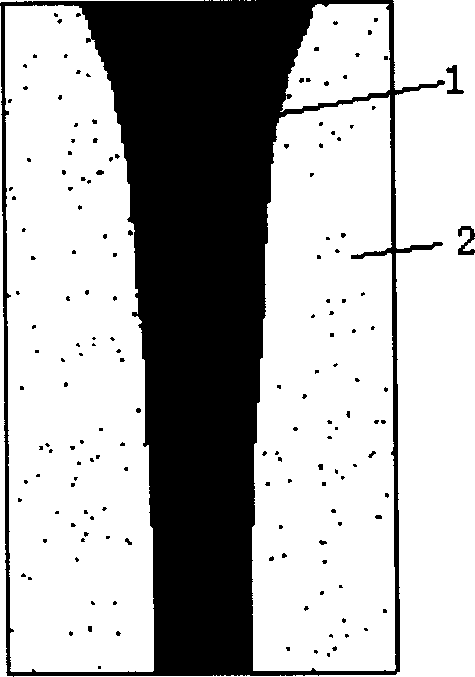

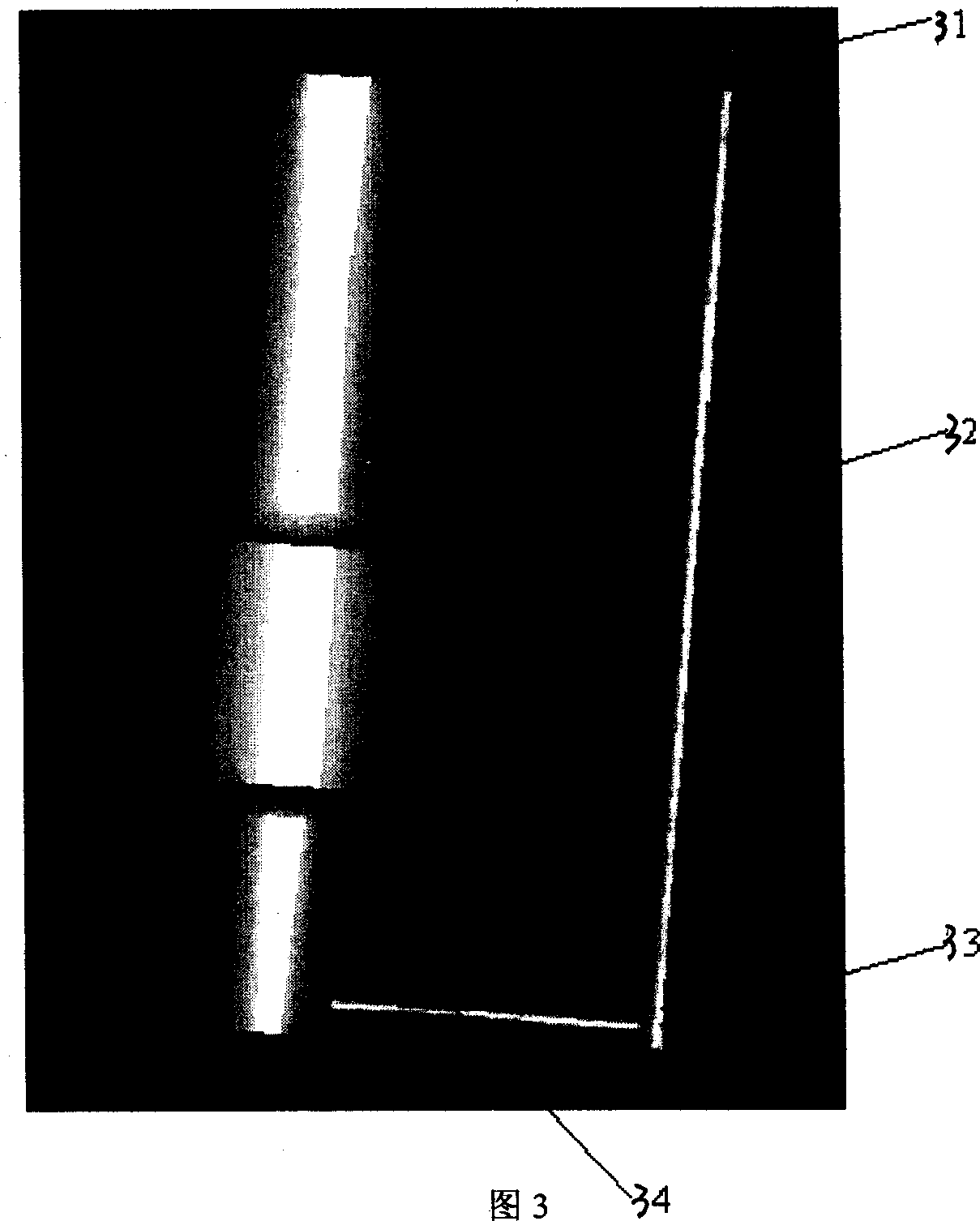

[0020] Such as Figure 4 As shown, the casting pouring method and system structure of the present invention are as follows: 1) Design the sprue cup according to the principle of smooth filling. A boss-type steady flow platform 48 is designed at the outlet end of the sprue cup, so that the molten metal does not splash during the filling process. The inner opening of the gate of the sprue cup is connected with a stopper system. When the molten metal is filled to 2 / 3 of the height of the sprue cup, the stopper system is opened, which is beneficial to the removal of oxidized inclusions during the filling process, and is also beneficial to the metal The liquid filling type is stable. 2) Adopt a streamlined sprue structure with a large top and a small bottom, and it is embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com