Passive containment cooling and pressure-reducing system

A passive containment and containment cooling technology, which is applied in the field of safety systems, can solve the problems of increasing the size of the containment, increasing the construction cost, increasing the difficulty of containment design and manufacturing, and achieving the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

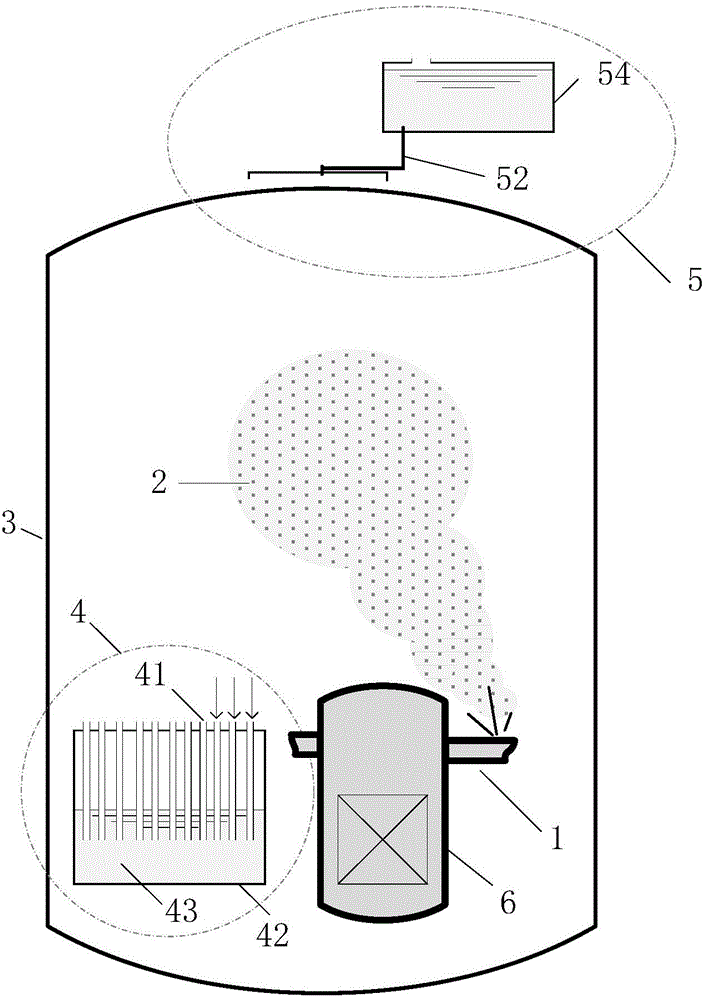

[0024] Such as figure 1 As shown, a reactor 6 is set inside the containment vessel 3 , and a passive containment vessel cooling and depressurization system according to the present invention includes a containment vessel depressurization subsystem 4 and a containment vessel cooling subsystem 5 .

[0025] The containment suppression subsystem 4 includes a suppression water tank 42 arranged in the containment vessel 3 , and a discharge channel 41 passing through the top of the suppression water tank 42 . Wherein, the suppressed water tank 42 is an airtight water tank or a pool, the upper part of the suppressed water tank 42 is an air space, and the lower part is water 43; , and the other end communicates with the atmosphere inside the containment vessel 3 .

[0026] The containment cooling subsystem 5 includes an external cooling pool 54 arranged above the exterior of the containment vessel 3 , and a pipeline 52 for spraying to the top of the containment is provided in the extern...

Embodiment 2

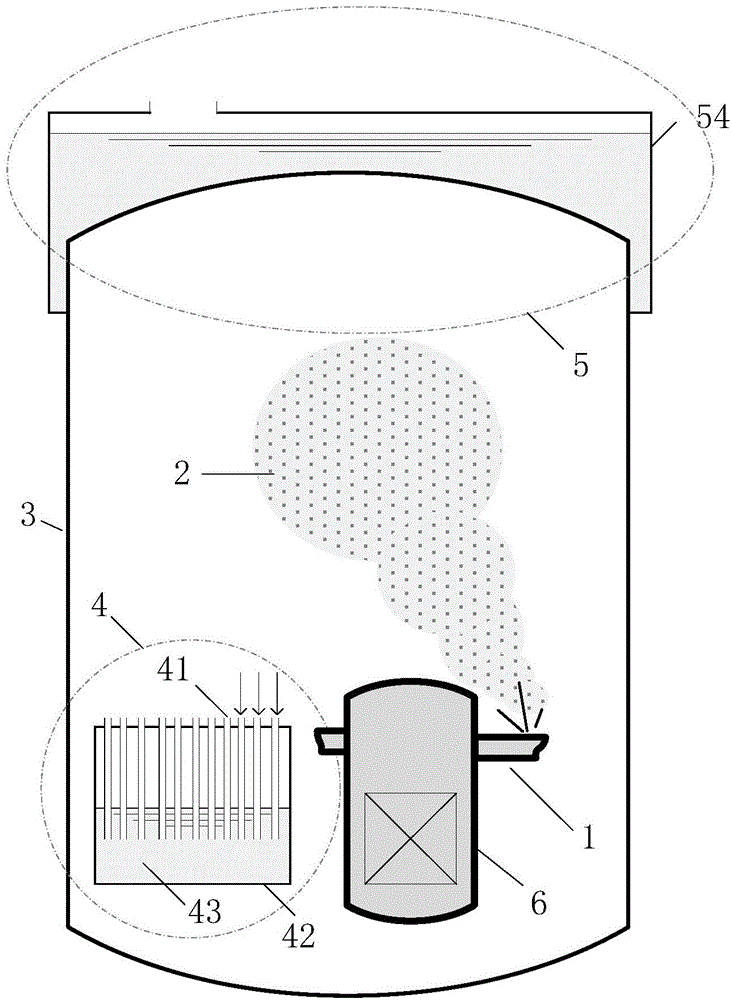

[0029] Such as figure 2 As shown, a reactor 6 is set inside the containment vessel 3 , and a passive containment vessel cooling and depressurization system according to the present invention includes a containment vessel depressurization subsystem 4 and a containment vessel cooling subsystem 5 .

[0030] The containment suppression subsystem 4 includes a suppression water tank 42 arranged in the containment vessel 3 , and a discharge channel 41 passing through the top of the suppression water tank 42 . Wherein, the suppressed water tank 42 is a closed water tank or pool, the upper part of the suppressed water tank 42 is the air space, and the lower part is the water 43; , and the other end communicates with the atmosphere inside the containment vessel 3 .

[0031] The containment cooling subsystem 5 includes an external cooling water pool 54 arranged outside the containment vessel 3 and submerging the containment vessel 3 .

[0032] When a breach accident occurs in a nuclea...

Embodiment 3

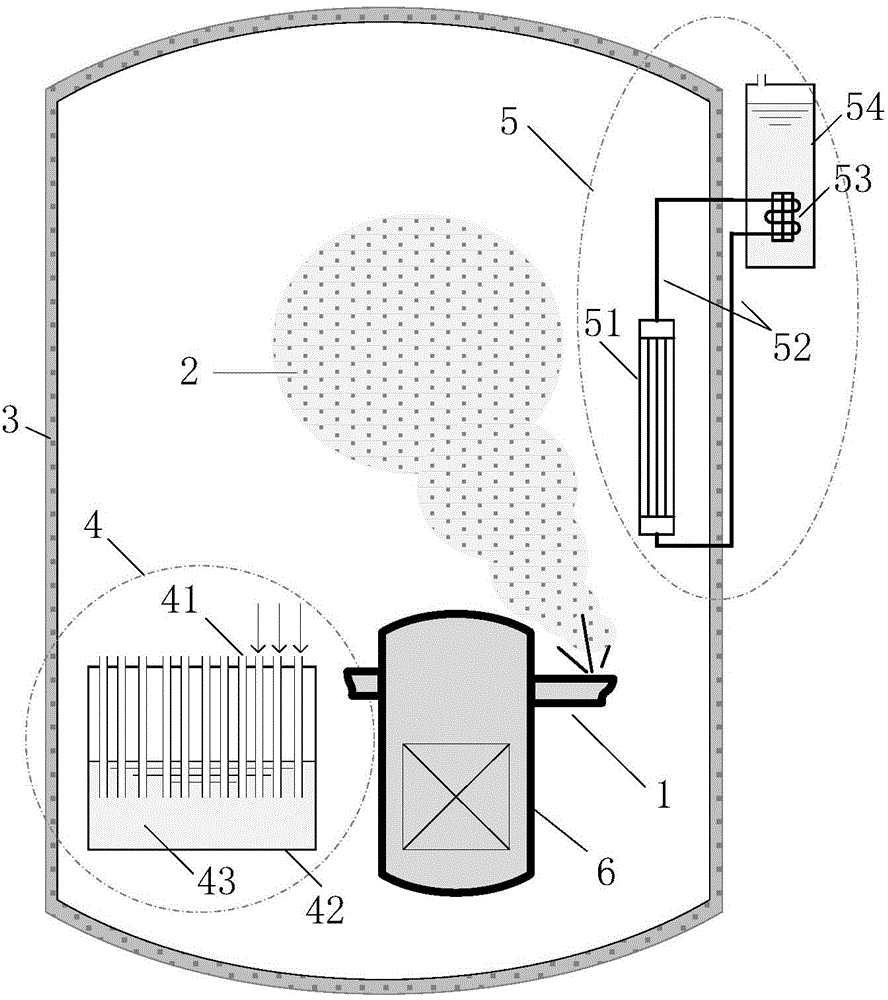

[0034] Such as image 3 As shown, a reactor 6 is set inside the containment vessel 3 , and a passive containment vessel cooling and depressurization system according to the present invention includes a containment vessel depressurization subsystem 4 and a containment vessel cooling subsystem 5 .

[0035] The containment suppression subsystem 4 includes a suppression water tank 42 arranged in the containment vessel 3 , and a discharge channel 41 passing through the top of the suppression water tank 42 . Wherein, the suppressed water tank 42 is a closed water tank or pool, the upper part of the suppressed water tank 42 is the air space, and the lower part is the water 43; , and the other end communicates with the atmosphere inside the containment vessel 3 .

[0036] The containment cooling subsystem 5 includes an in-shell condenser 51 arranged inside the containment vessel 3, an outer-shell cooling water pool 54 arranged outside the containment vessel 3, and an outer-shell cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com