Casting method capable of preventing precise investment casting from generating hot-spot shrinkage holes

A technology for precision castings and thermal joints, applied in the fields of precision casting and casting, can solve the problems of reduced production efficiency, increased casting costs, wasted man-hours and costs, and achieved the effect of saving man-hours and costs, reducing casting costs, and improving surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

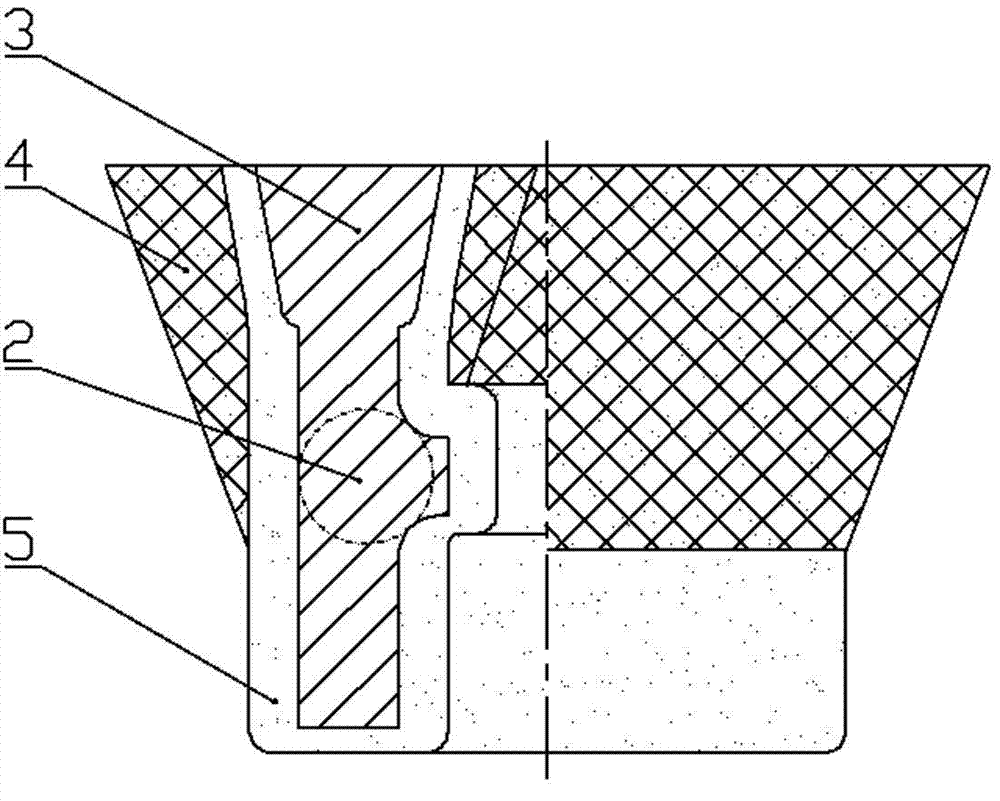

[0034] see Figure 1 to Figure 3 , a casting method for preventing thermal shrinkage cavities in investment castings, comprising the following steps:

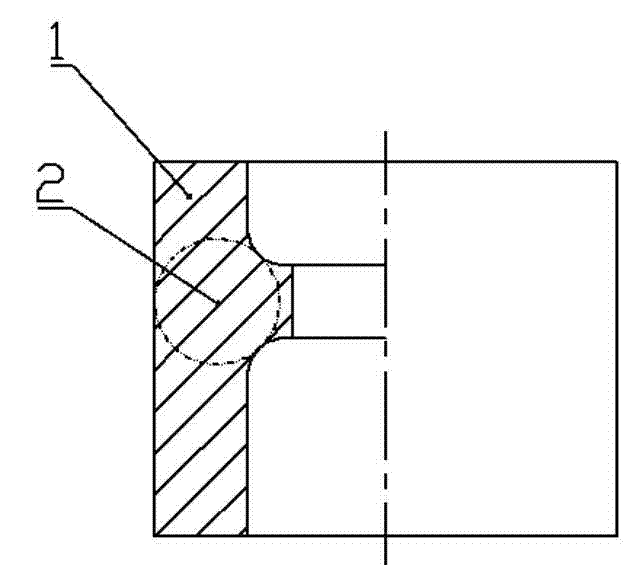

[0035] (1) For attached figure 1 The position and height of the riser 3 are determined according to the existing technology in the casting 1 shown in the figure. The thickness of the riser root is increased by 5% to 10% compared with the wall thickness of the casting here. Mouth metal subsidy thickness.

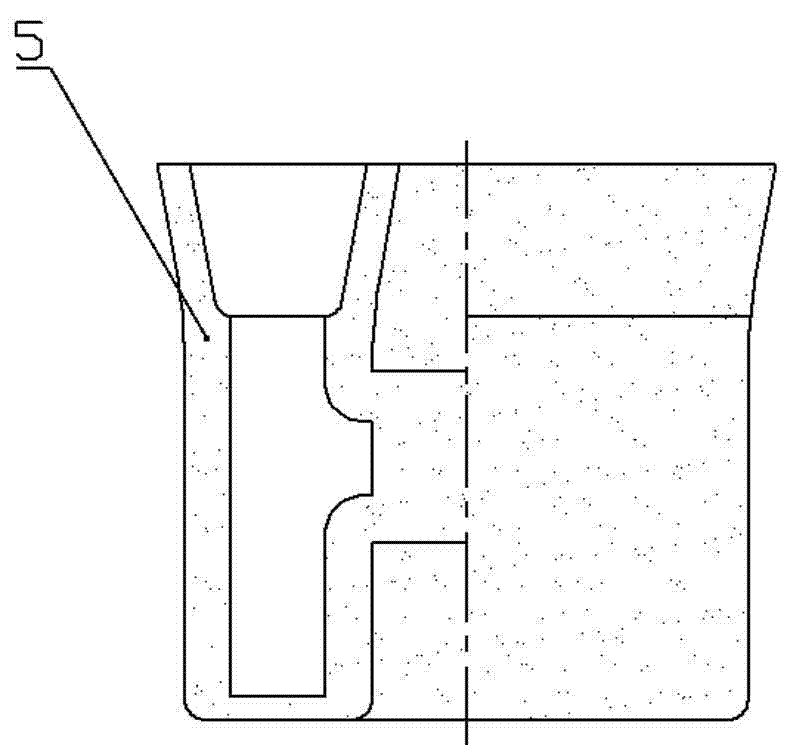

[0036] (2) Dip, sand and dewax the same as normal parts. to obtain a shell that is approximately uniform throughout the shell thickness (see e.g. figure 2 ).

[0037] (3) Use back layer slurry: back layer powder: back layer sand = 1:1:5 mass ratio to mix mortar and mud paste. Mortar paste must be viscous, and after the shell subsidy is made, it will not creep or flow when placed.

[0038] (4) Determine the position and area of the riser shell subsidy according to the conventional technology. The area of the riser sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com