Electronic ink microcapsule and manufacture method of electronic ink microcapsule

An electronic ink and microcapsule technology, applied in the directions of microcapsule preparation, microsphere preparation, ink, etc., to avoid deterioration, improve barrier properties, avoid shrinkage cavities and prevent the backplane from being wetted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

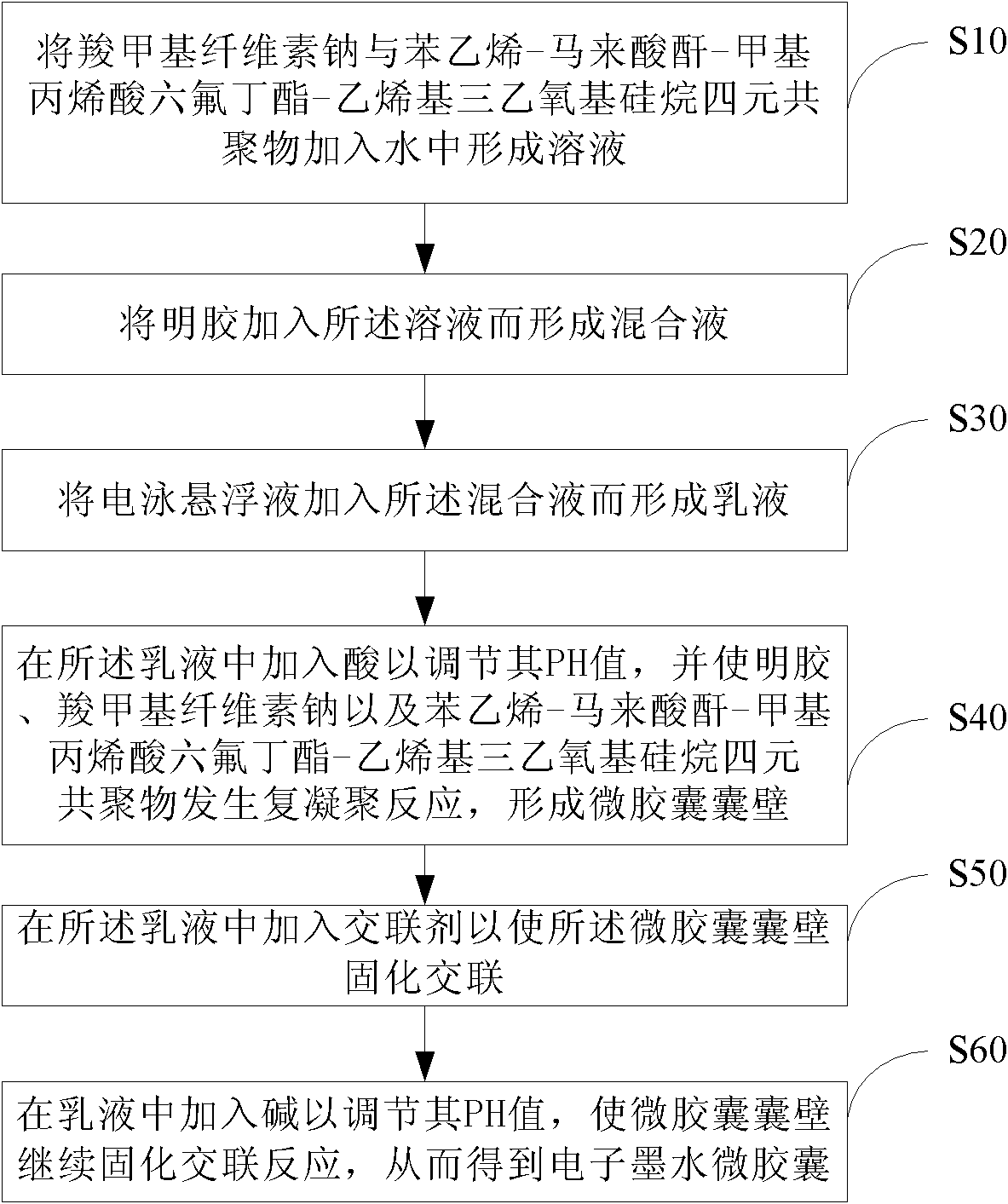

Method used

Image

Examples

Embodiment 1

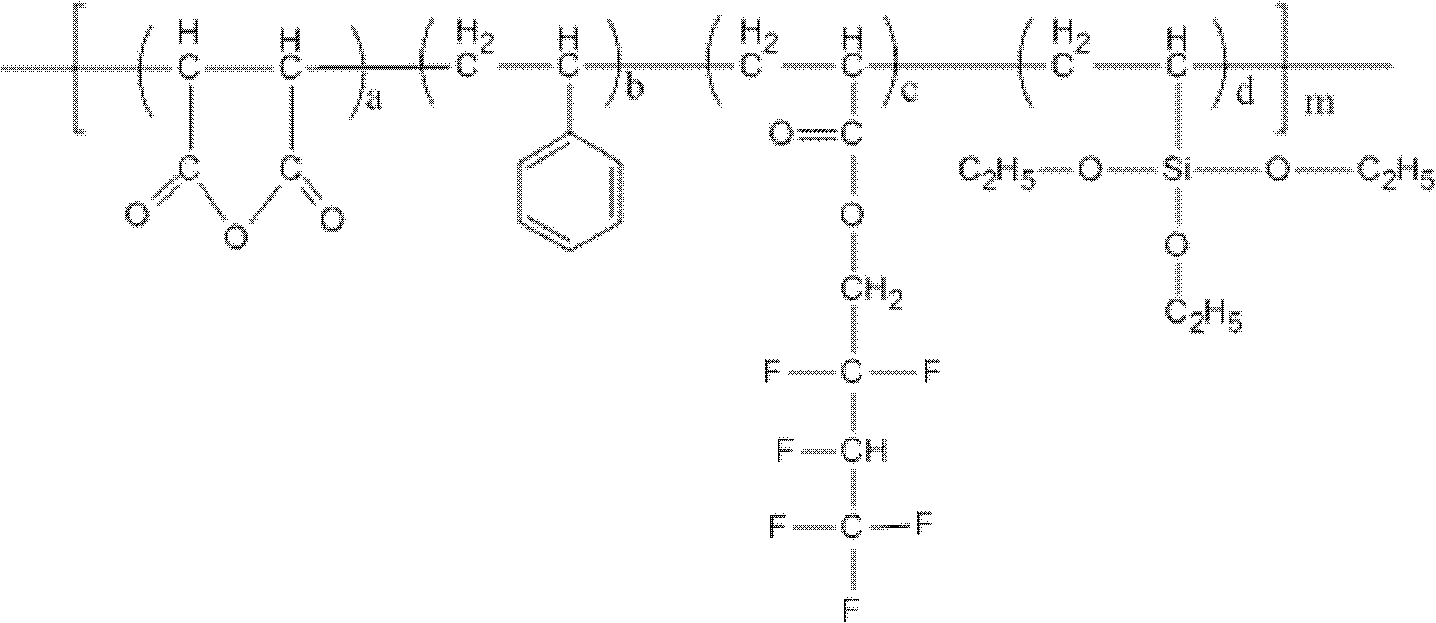

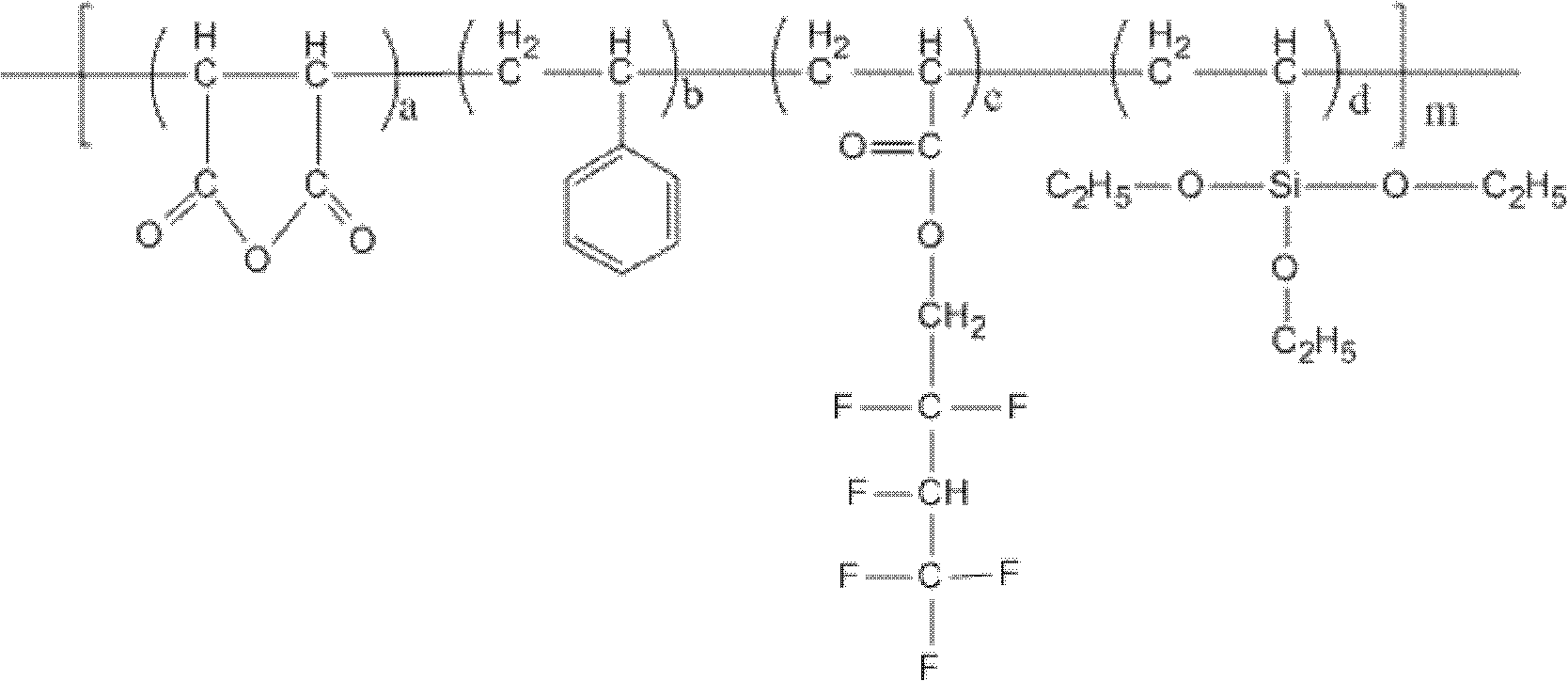

[0073] a. the hydrolyzate of sodium carboxymethylcellulose and styrene-maleic anhydride-hexafluorobutyl methacrylate-vinyl triethoxysilane tetrapolymer in a mass ratio of 1:1 is added to water, and Dissolve it completely at a temperature of 40°C to form a solution;

[0074] b. adding the gelatin aqueous solution to the solution obtained in step a to form a mixed solution, wherein the mass ratio of gelatin to sodium carboxymethylcellulose is 0.5:1;

[0075] c. Add the electrophoretic suspension to the mixed solution obtained in step b, and stir until an O / W emulsion is formed, wherein the electrophoretic suspension is mixed with gelatin, sodium carboxymethylcellulose and styrene-maleic anhydride-methacrylic acid The mass ratio of the hydrolyzate of hexafluorobutyl-vinyltriethoxysilane tetrapolymer is 100:1;

[0076] d. Adding hydrochloric acid with a concentration of 0.05% by mass, the pH value of the emulsion is adjusted to 2, and gelatin, sodium carboxymethylcellulose and st...

Embodiment 2

[0080] a. the hydrolyzate of sodium carboxymethylcellulose and styrene-maleic anhydride-hexafluorobutyl methacrylate-vinyl triethoxysilane tetrapolymer in a mass ratio of 20:1 is added to water, and Dissolve it completely at a temperature of 40°C to form a solution;

[0081] b. adding the gelatin aqueous solution to the solution obtained in step a to form a mixed solution, wherein the mass ratio of gelatin to sodium carboxymethylcellulose is 5:1;

[0082] c. Add the electrophoretic suspension to the mixed solution obtained in step b, and stir until an O / W emulsion is formed, wherein the electrophoretic suspension is mixed with gelatin, sodium carboxymethylcellulose and styrene-maleic anhydride-methacrylic acid The mass ratio of the hydrolyzate of hexafluorobutyl ester-vinyltriethoxysilane tetrapolymer is 60:1;

[0083]d. Adding hydrochloric acid with a concentration of 0.5% by mass, the pH value of the emulsion is adjusted to 3, and gelatin, sodium carboxymethylcellulose and ...

Embodiment 3

[0087] a. the hydrolyzate of sodium carboxymethylcellulose and styrene-maleic anhydride-hexafluorobutyl methacrylate-vinyl triethoxysilane tetrapolymer in a mass ratio of 50:1 is added to water, and Dissolve it completely at a temperature of 40°C to form a solution;

[0088] b. adding the gelatin aqueous solution to the solution obtained in step a to form a mixed solution, wherein the mass ratio of gelatin to sodium carboxymethylcellulose is 20:1;

[0089] c. Add the electrophoretic suspension to the mixed solution obtained in step b, and stir until an O / W emulsion is formed, wherein the electrophoretic suspension is mixed with gelatin, sodium carboxymethylcellulose and styrene-maleic anhydride-methacrylic acid The mass ratio of the hydrolyzate of hexafluorobutyl ester-vinyltriethoxysilane tetrapolymer is 20:1;

[0090] d. adding hydrochloric acid with a mass percent concentration of 2%, the pH value of the emulsion is adjusted to 4, and gelatin, sodium carboxymethylcellulose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com