Die of cast aluminum shell for high pressure switch, and method for producing cast aluminum shell

A high-voltage switch, cast aluminum technology, applied in the field of metal mold forming, can solve the problems of low one-time pass rate, local coarse grains, low production efficiency, etc., and achieve high air tightness inspection pass rate, low production cost, convenient control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the drawings.

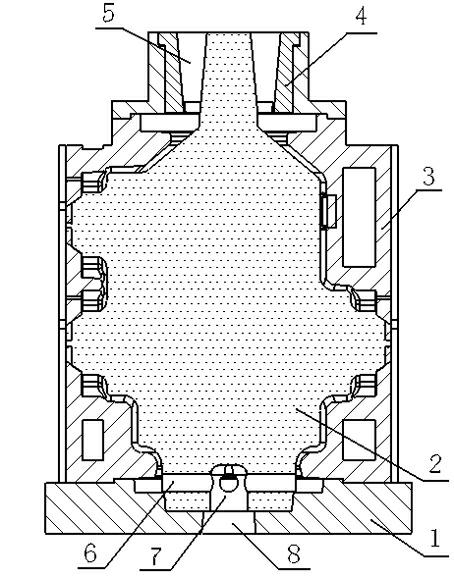

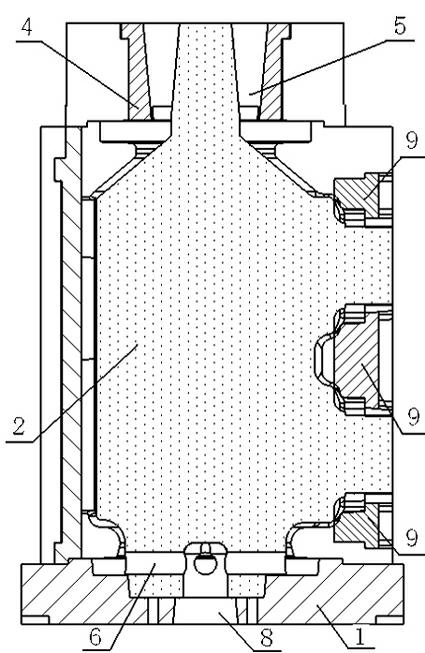

[0027] figure 2 Is a schematic diagram of the main cross-sectional structure of the mold, image 3 for figure 2 The left-side cross-sectional structure diagram of the middle mold, as shown in the figure, the bottom plate 1 is provided with an inlet 8 connected with the crucible riser pipe, and connected with the inlet 8 is the sprue 7 at the bottom of the sand core 2 and the sprue 7 There are 4 evenly distributed inner runners 6; the sand core 2 is wrapped with a metal mold 3, and the top of the metal mold 3 is provided with a riser core 4, the inner side of the riser core 4 and the upper outer side of the sand core 2 form a riser 5. There are 3 inserts 9 distributed longitudinally on the side of the sand core 2.

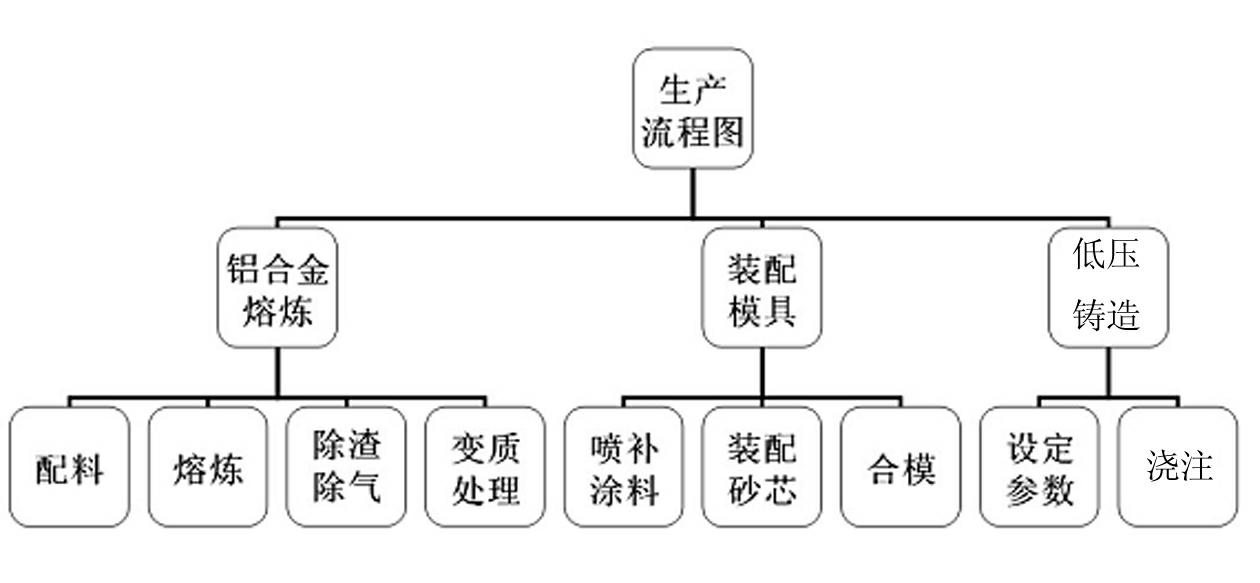

[0028] figure 1 It is the production process flow chart of the present invention, as shown in the figure, including the following steps:

[0029] (1) Aluminum alloy smelti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com