Gravity casting method and device for piston

A technology of gravity casting and piston, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of difficult quality assurance, low process yield rate, low production efficiency, etc., and achieve low cost, high process yield rate, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

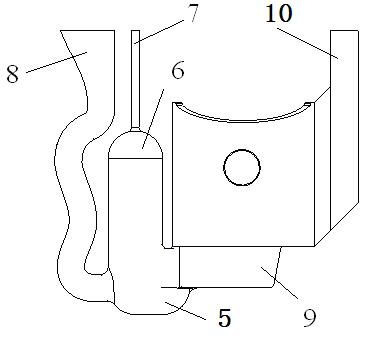

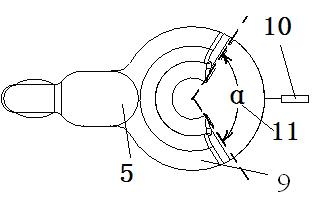

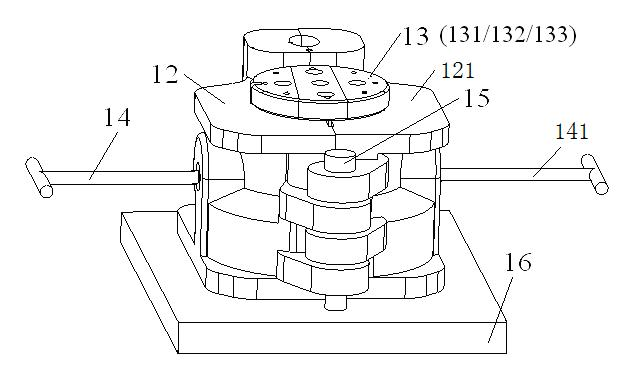

[0025] Hereinafter, preferred embodiments of the present invention and its manufacturing method will be described in detail with reference to the drawings.

[0026] The piston of the traditional process cannot guarantee smooth filling and smooth exhaust, and the shrinkage cavity is mainly distributed in the 4 hot joint circles of the lower side ring groove of the piston pin hole. The research combined with the specific production practice, the casting of the aluminum piston manual gravity casting process The cause of the defect was analyzed, the structure of the pouring system was changed, the shrinkage cavity at the thick part of the piston head was effectively eliminated, and the yield and process yield were improved.

[0027] The material of the test sample is Al-Si eutectic alloy which is widely used in engine pistons. This alloy has good castability, weldability and thermal conductivity, and has high strength and good thermal conductivity Corrosion resistance. The piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com