Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

A nodular cast iron and yaw technology, which is applied in the field of casting, can solve the problems of high labor intensity, poor precision of castings, and high difficulty in production, and achieve the effects of low environmental pollution, good surface quality, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiments:

[0029] The manufacturing method of the ductile iron castings of the wind power yaw pitch converter of the present invention includes the following steps:

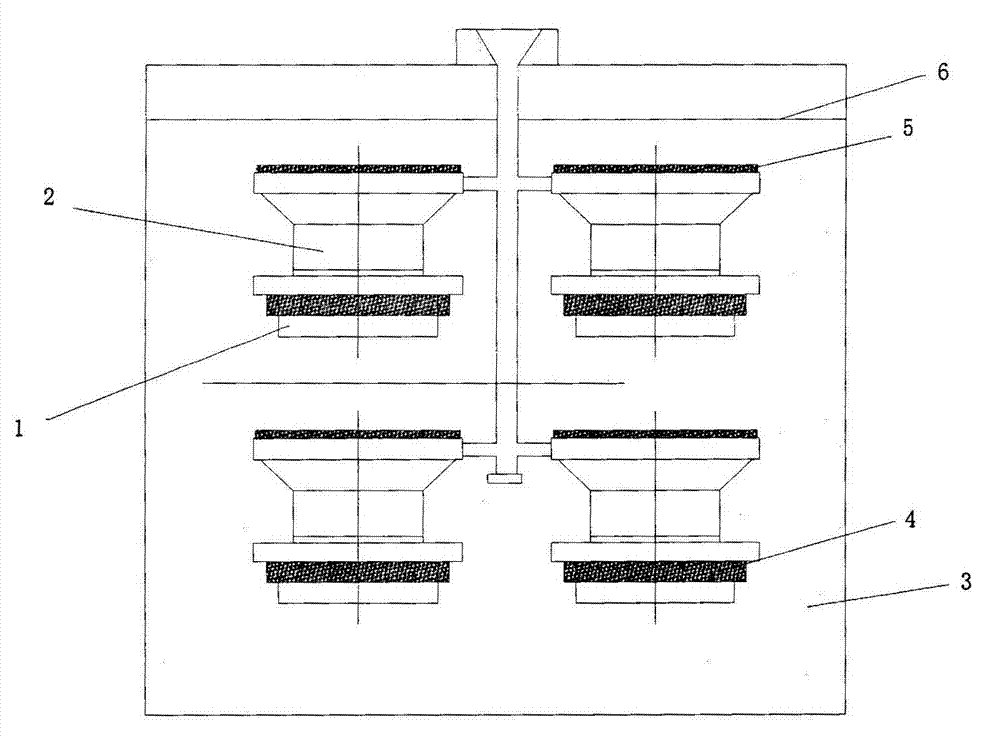

[0030] a. Mold making: According to the structural characteristics of various yaw pitch devices, choose to make them into integral or split molds;

[0031] b. Foaming moulding: inject the copolymerized EPMMA material into the lost foam mold to make a whole or split yaw pitcher lost foam, then dry, repair the mold and bond the split lost foam together to form The lost foam is exactly the same as the yaw variable pitcher casting, and the inner gate and runner are glued on the lost foam;

[0032] c. Paint brushing: Brush the evaporative foam paint on the evaporative foam by dipping, eliminate air bubbles, and dry it in a drying room at 40-50℃ for 8-10 hours. Do this two to three times to make the coating thickness reach 1-2mm; The molding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com