Pouring process for extrusion casting

A pouring method and squeeze casting technology, which are applied in the field of squeeze casting and pouring, can solve the problems of difficulty in pouring, difficulty in anti-oxidation protection, and high energy consumption in smelting, shorten the process cycle period, facilitate anti-oxidation protection, and improve process yield. yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

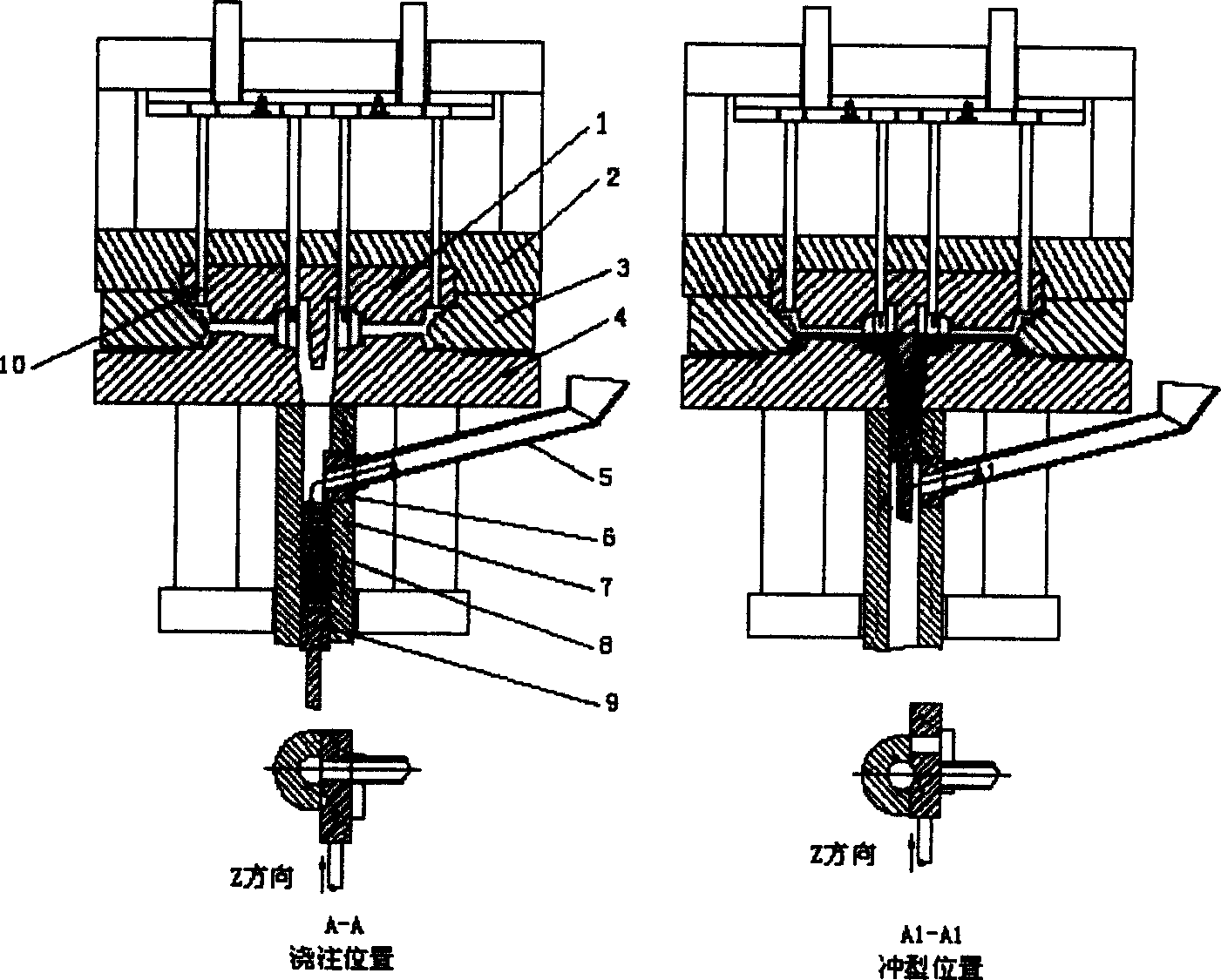

[0009] The following is attached with the manual figure 1 And implementation case further illustrates the present invention:

[0010] The implementation case takes the extrusion casting of magnesium alloy wheels as an example, and the process is as follows:

[0011] 1. Clean the mold, apply paint, close the mold, and reset the pressure head;

[0012] 2. Pouring: The magnesium alloy melt is poured into the pressure chamber 7 through the quantitative pouring device 5 and gate slider 6 on the side of the pressure chamber, and then the gate slider 6 quickly slides to the filling position along the Z direction;

[0013] 3. Mold filling, pressure keeping and solidification: the magnesium alloy melt in the pressure chamber 7 quickly enters the cavity under the action of the indenter 9. After the mold filling is completed, the indenter 9 continues to maintain the magnesium alloy melt in the mold. Press until the casting is completely solidified;

[0014] 4. Mold opening and pick-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com