One-box multi-piece casting mold and casting method for brake disc castings

A technology for brake discs and castings, which is applied in the field of multiple molds and castings in one box of brake disc castings. It can solve the problems of high production cost, low production efficiency, and low process yield, so as to reduce the ratio of sand to iron and improve production efficiency. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the description.

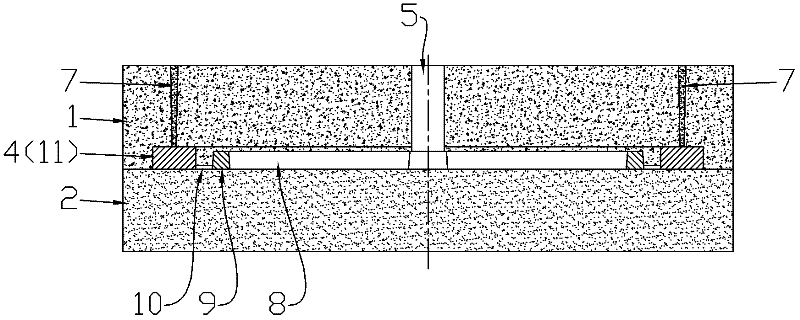

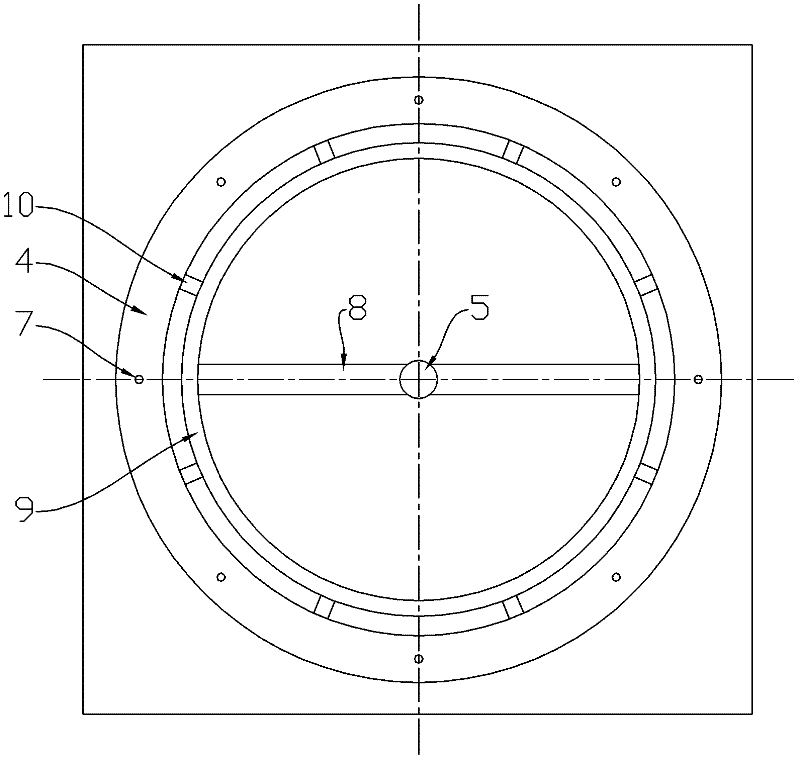

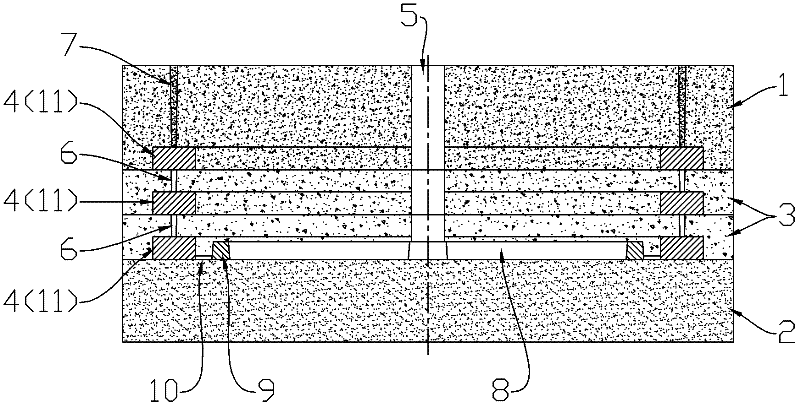

[0027] A kind of scheme of one case multi-piece casting method of brake disc casting of the present invention is to rely on image 3 As shown in the mold, the brake disc castings have a multi-piece mold including an upper case 1, a lower case 2 and at least one middle case 3, and the upper case 1, the middle case 3, and the lower case 2 are stacked from top to bottom, each A circular brake disc cavity 4 and a sprue 5 are made in the middle case 3 and the upper case 1, and each sprue is connected up and down, and a plurality of connected brake disc cavities are respectively made in each middle case 3. Upright ingate 6, a plurality of outlet rods 7 connected to the brake disc cavity are vertically placed in the upper box 1, and the lowermost middle box is also made with runner 8, sub-runner 9, and horizontal ingate 10. The sub-runner 9 is circular and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com