Wind energy yaw brake disc integrated side vertical casting sand box

A brake disc and yaw technology is applied in the field of wind energy yaw brake disc integrated side vertical casting sand box, which can solve the problems of high production cost, low process yield, low finished product qualification rate, etc., to reduce the sand-iron ratio and improve the The qualified rate of finished products and the effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

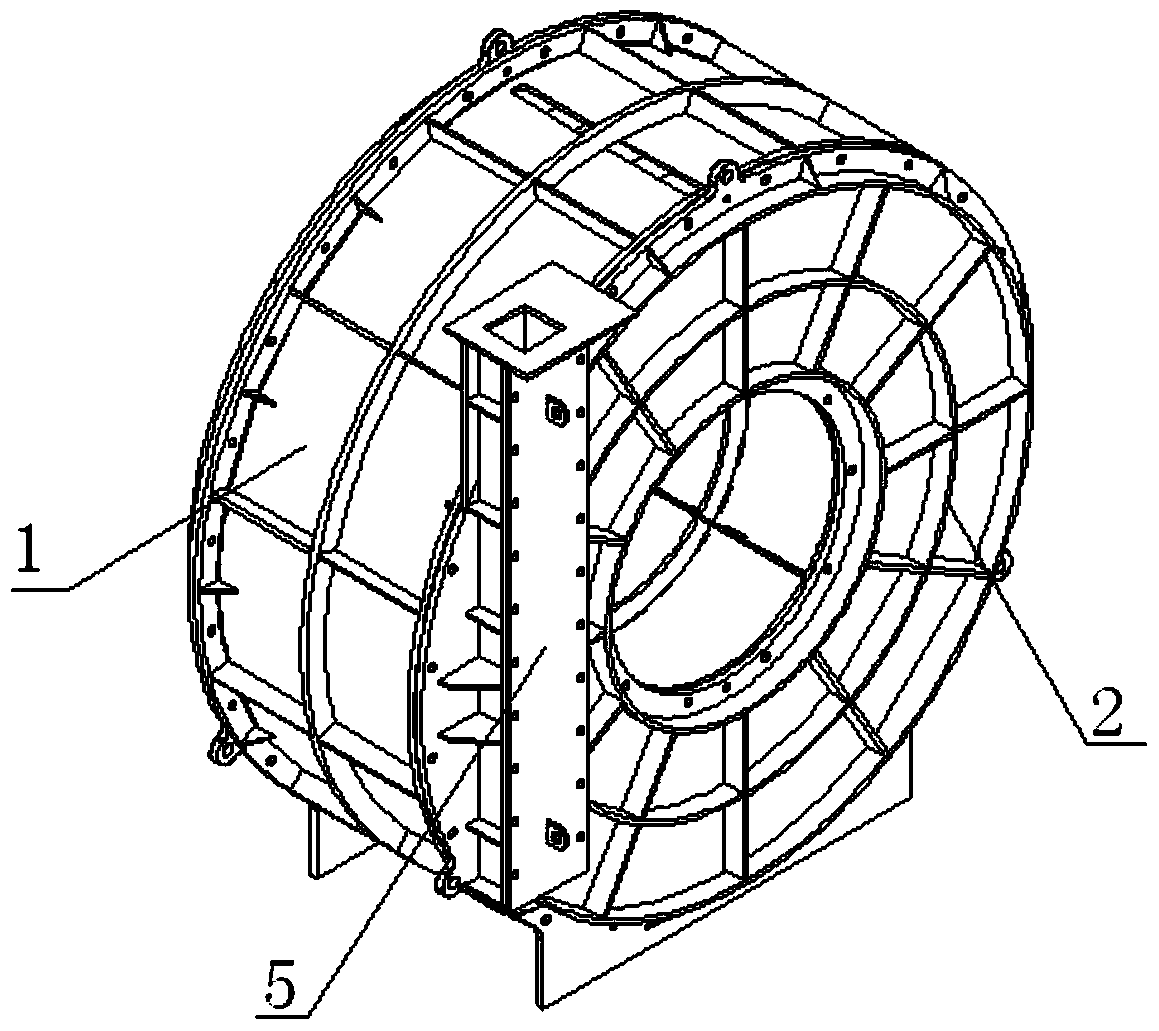

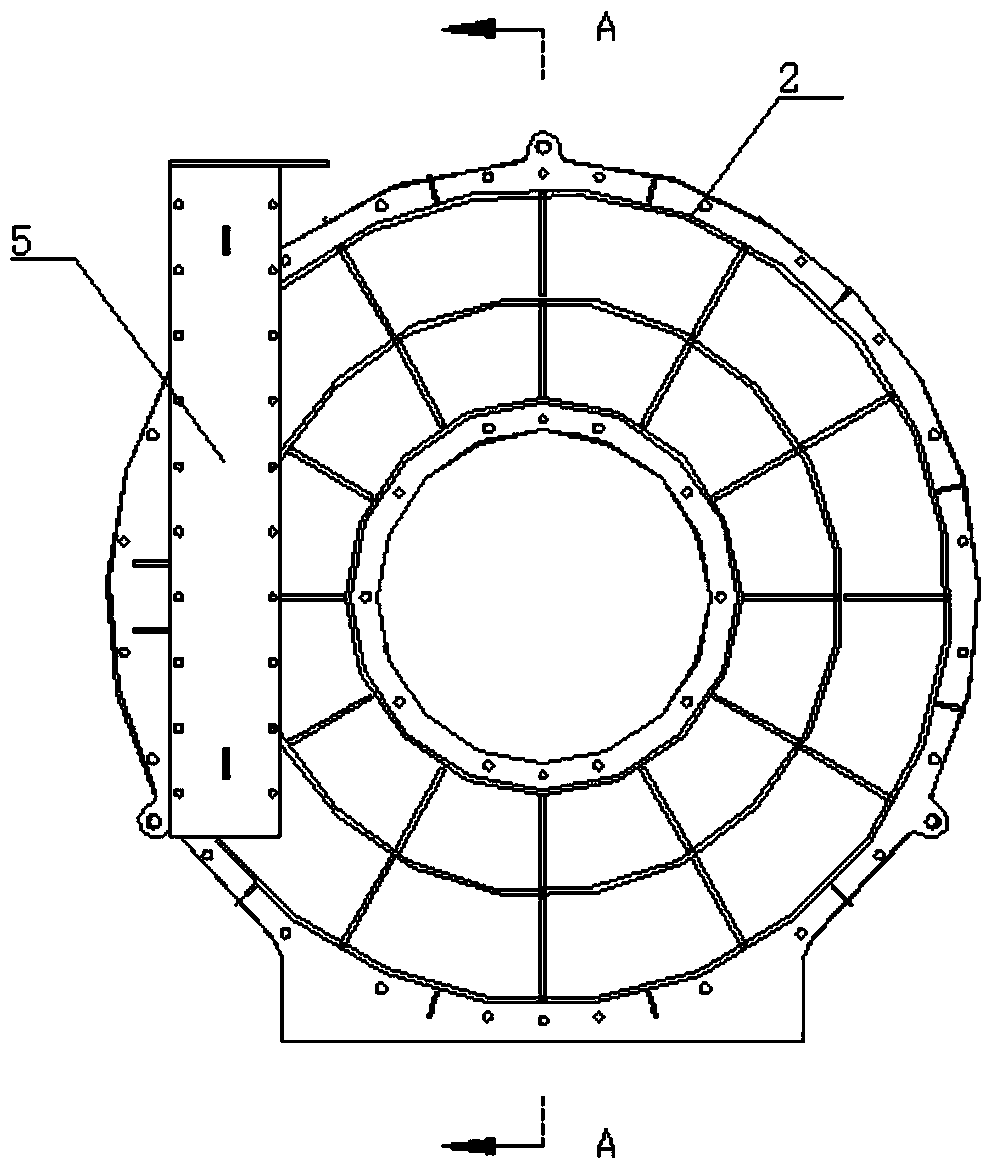

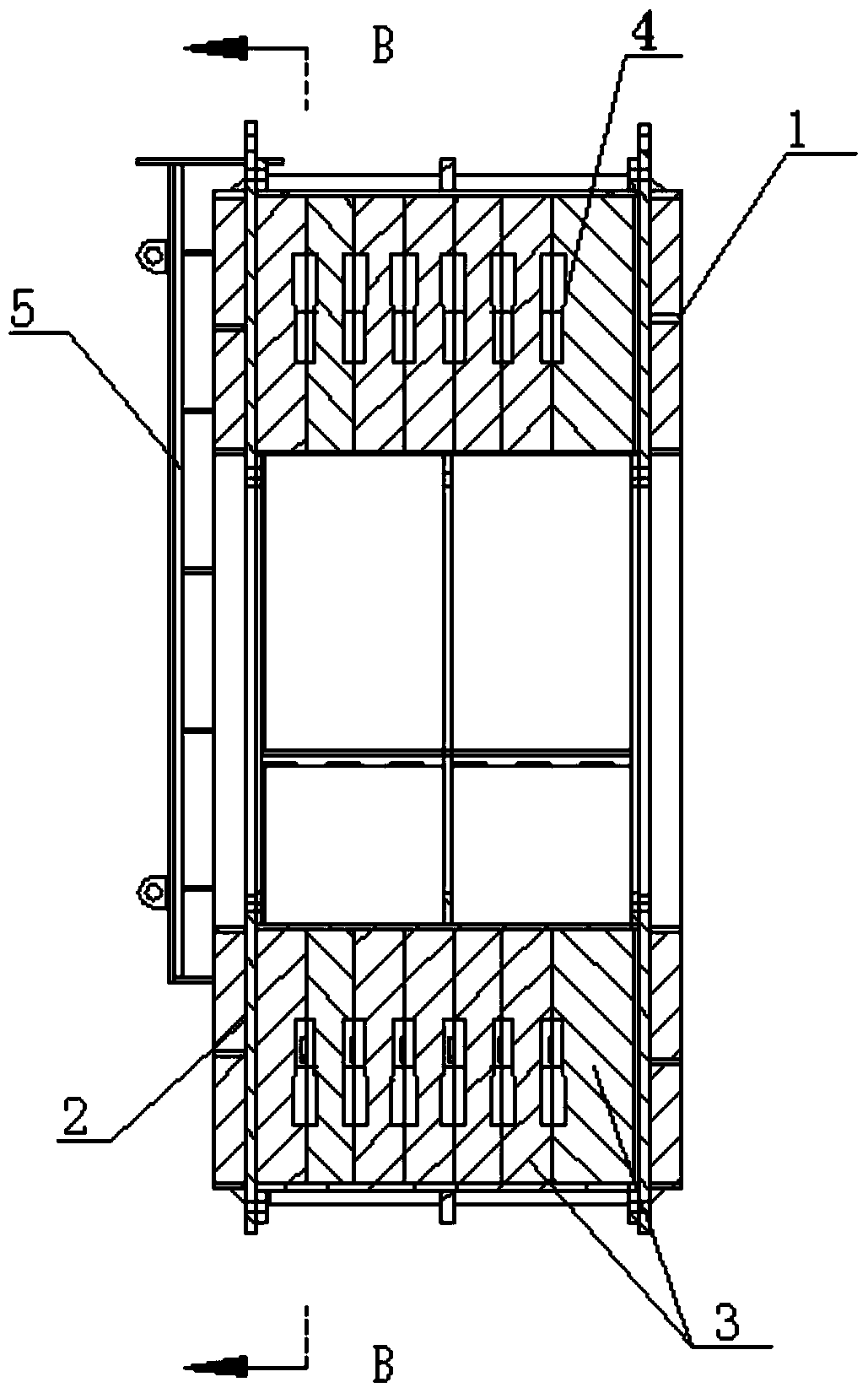

[0022] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a wind energy yaw brake disc integrated side casting sand box includes a hollow annular cylindrical sand box main body 1 and a box cover 2 for closing the opening of the sand box main body. A plurality of sand molds 3 stacked in sequence from left to right, a yaw brake disc cavity 4 is formed in two adjacent sand molds; a vertical sprue 5 is provided on the box cover, and the sand A horizontal runner communicating with the vertical runner and the cavity of the yaw brake disc is formed on the mold.

[0023] Preferably, the flask is a core-assembling type, and each molding sand mold is composed of a plurality of fan-shaped co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com